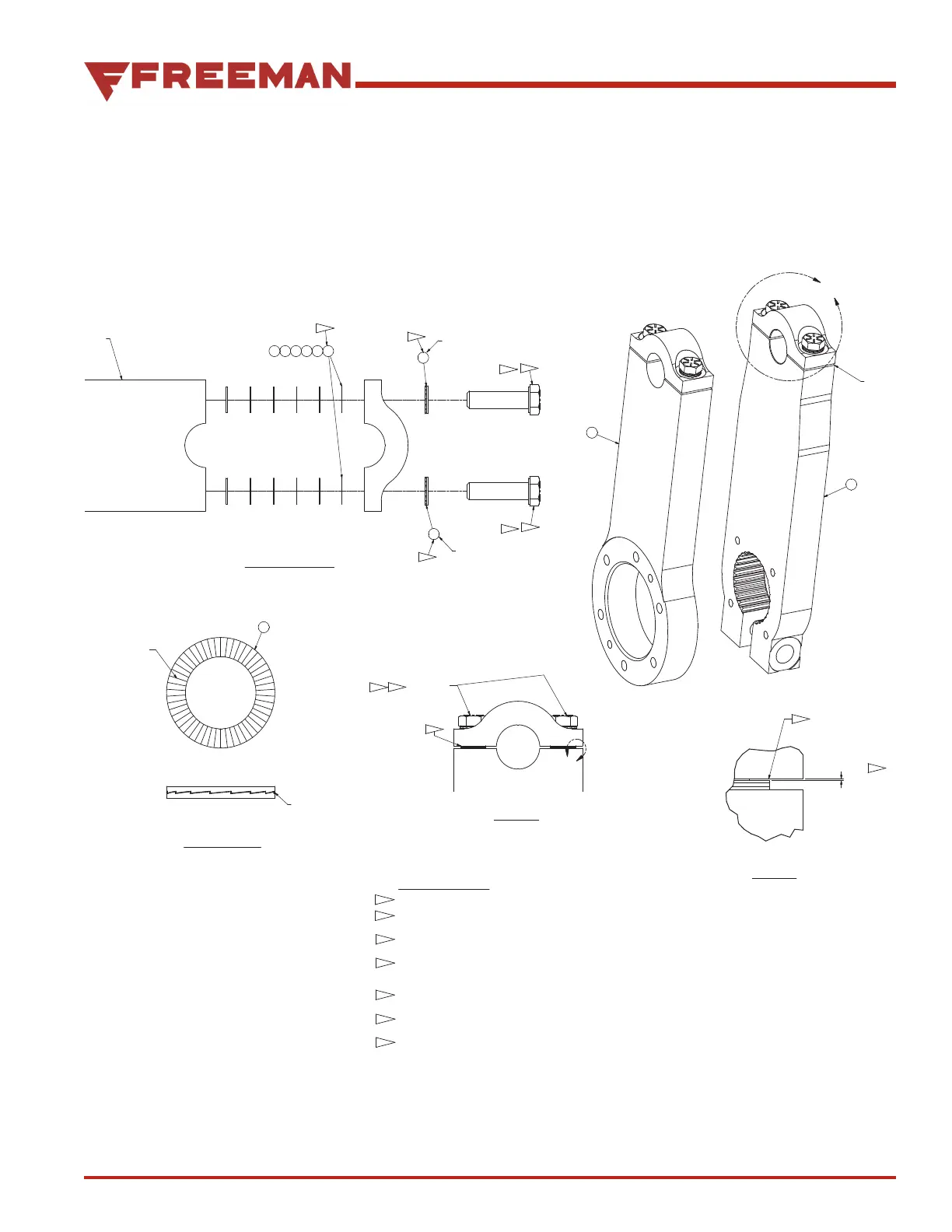

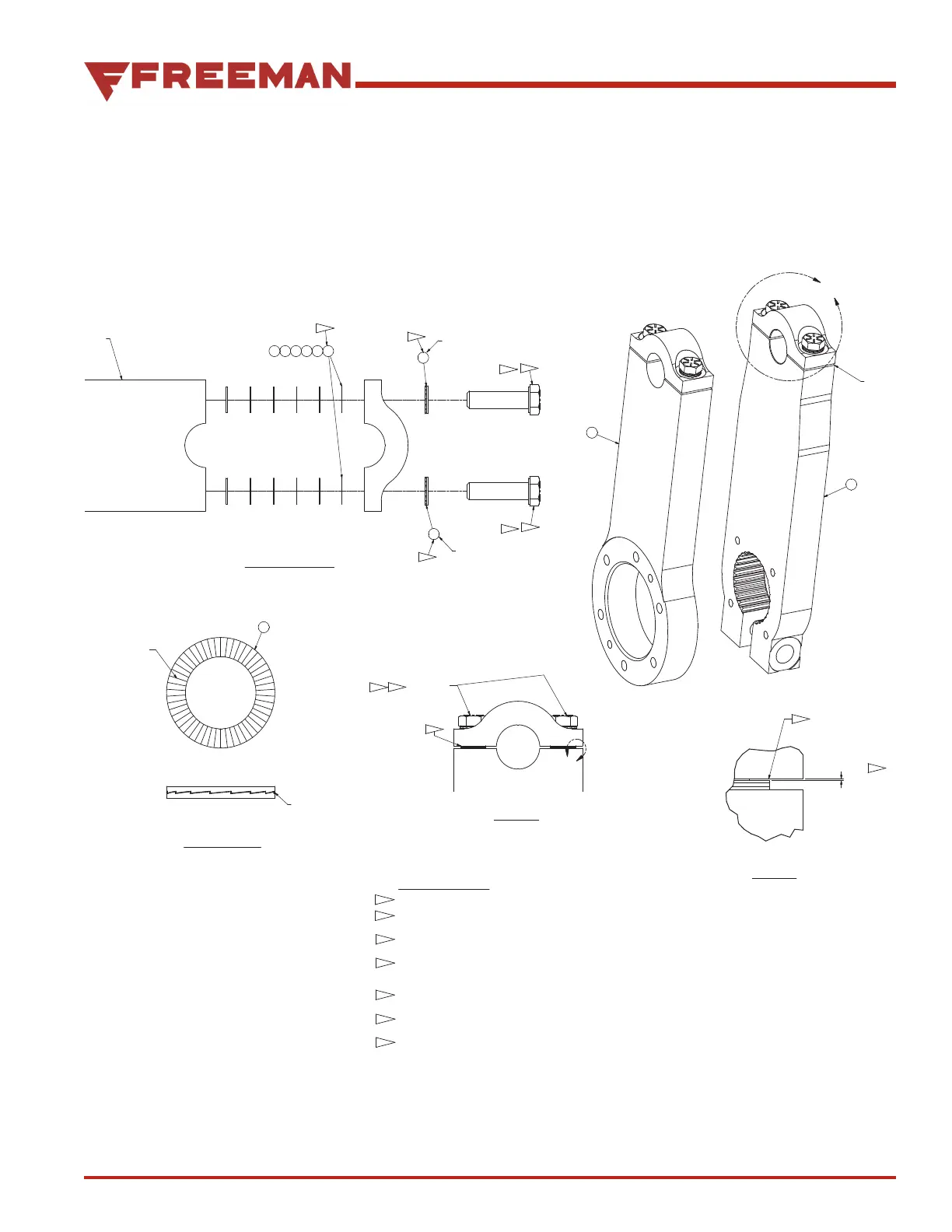

CAP INSTALLATION

SAME FOR 904466 & 906841

DETAIL E

WASHER DETAIL

DETAIL F

INSTALLATION NOTES:

USE THE HARDWARE PROVIDED WITH THE ARM.

INSTALL ITEM 36 SERRATED EDGES FACING OUT AND WEDGE

FEATURES MESHED.

PLACE CAP ON SHAFT, HAND TIGHTEN BOLTS, MEASURE

GAP (BOTH SIDES) BETWEEN CAP & CRANK/DRIVE ARMS.

SHIM AS REQUIRED TO ACHIEVE A GAP 0.010 " OR LESS WHEN

BOLT IS HAND TIGHT. GAP DOES NOT NEED TO BE THE

SAME ON BOTH SIDES.

RE-ASSEMBLE WITH SHIMS, HAND TIGHTEN BOLTS AND CONFIRM

GAP (MAX 0.010") BEFORE TIGHTENING.

TORQUE BOLTS EVENLY TO 340 FT-LB. TORQUE BOTH B

OLTS

FIRST TO 100 FT-LB, THEN TO 200 FT-LB AND FINALLY TO 340 FT-LB.

INSPECT BOLTED CONNECTION TO CONFIRM GAP IS ELIMINATED

(BOTH SIDES).

FASTENERS

HAND TIGHT

ARM

WEDGE FEATURES

SERRATED EDGES

BOTH SIDES

3-2

3-3

3-4

3-5

3-6

3-7

3-1

3-3

3-5

SHIMS

3

4

3-1

36

3-1

3-6

3-6

3-7

3-7

36

36

373839

40

4142

3-5

SEE

WASHER DETAIL

SEE

WASHER DETAIL

3-2

3-2

GAP .010" MAX

3-4

E

F

Gearbox Installation 14”X21”KTD (16” Frame)

Page 5 of 5

45

89-096Rev: 11-2016

Loading...

Loading...