Cleaning, maintenance and repairs

UX01 Super CP Plus BAG0157.3 03.18

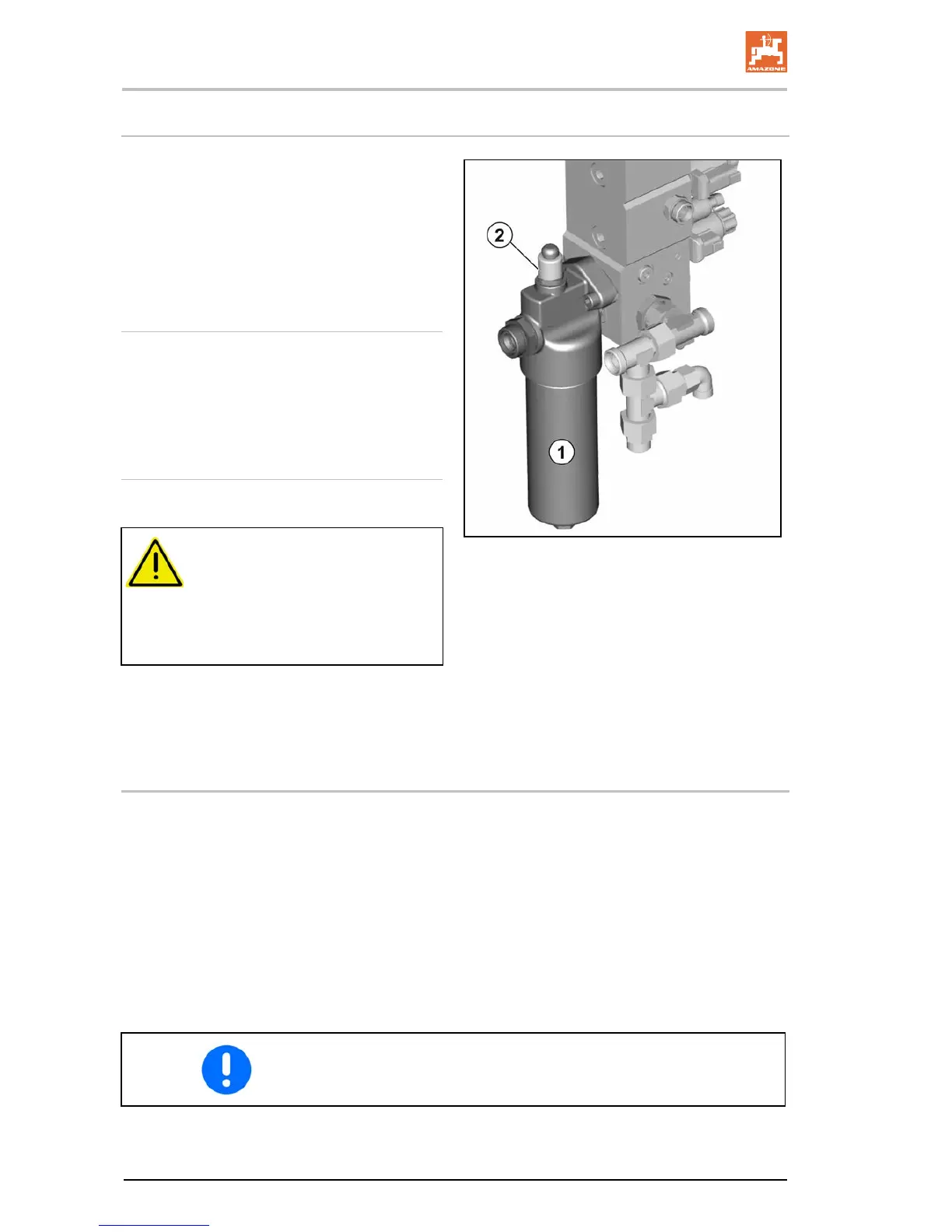

• Oil filter for Profi-folding

• Oil filter for hydraulic pump drive

Hydraulic oil filter (1) with contamination indicator

(2).

• Green Filter is working

• Red Replace filter

Checking the oil filter for contamination

The hydraulic oil must have reached operating

temperature.

1. Press in the contamination indicator.

2. Continue working with the implement.

3. Observe the contamination indicator.

Replacing the oil filter

To dismantle the filter, unscrew the filter lid and

remove the filter.

CAUTION

Depressurise the hydraulic system

beforehand.

Otherwise, there is danger of injuries

from escaping hydraulic oil at high

pressure.

After replacing the oil filter, press the contamina-

tion indicator back down.

Green ring is visible again.

14.11.6 Adjusting the hydraulic throttle valve

The operating speeds for the individual hydraulic functions are

set at the factory using the respective hydraulic throttle valves

on the valve block (fold/unfold sprayer boom, lock/unlock the vibra-

tion compensation, etc.). However, depending on the type of

may be necessary to correct these speed settings.

The operating speed for a hydraulic function associated with a par-

ticular throttle pair can be adjusted by screwing the hexagon socket

head screw on the corresponding throttle in or out.

• Reduce operating speed = screw in hexagon socket head screw.

• Increase operating speed = screw out hexagon socket head

screw.

Always adjust the two throttles in a throttle pair equally when correct-

ing the operating speed of a hydraulic function.

Loading...

Loading...