43

OPERATION MANUAL

© AMETEK, Inc.

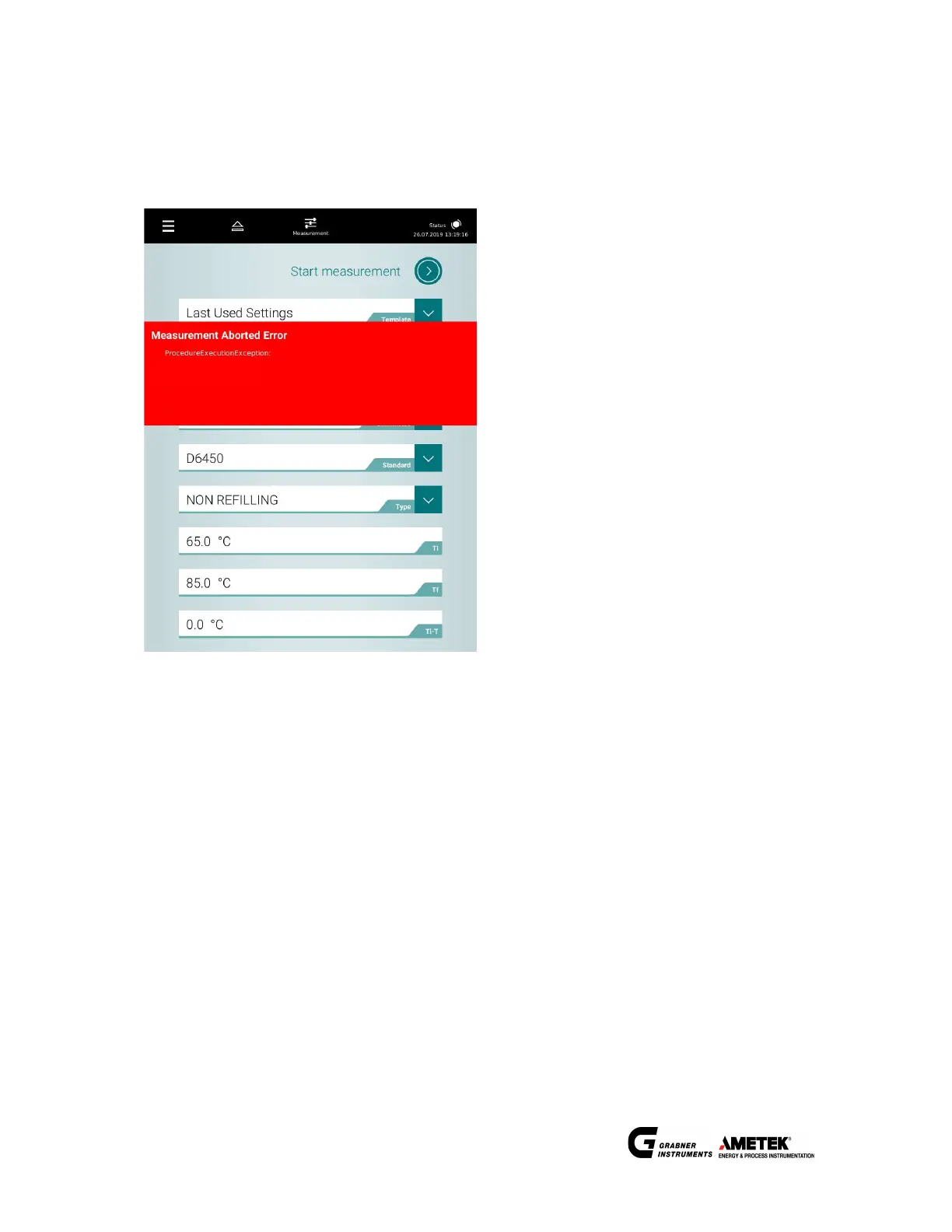

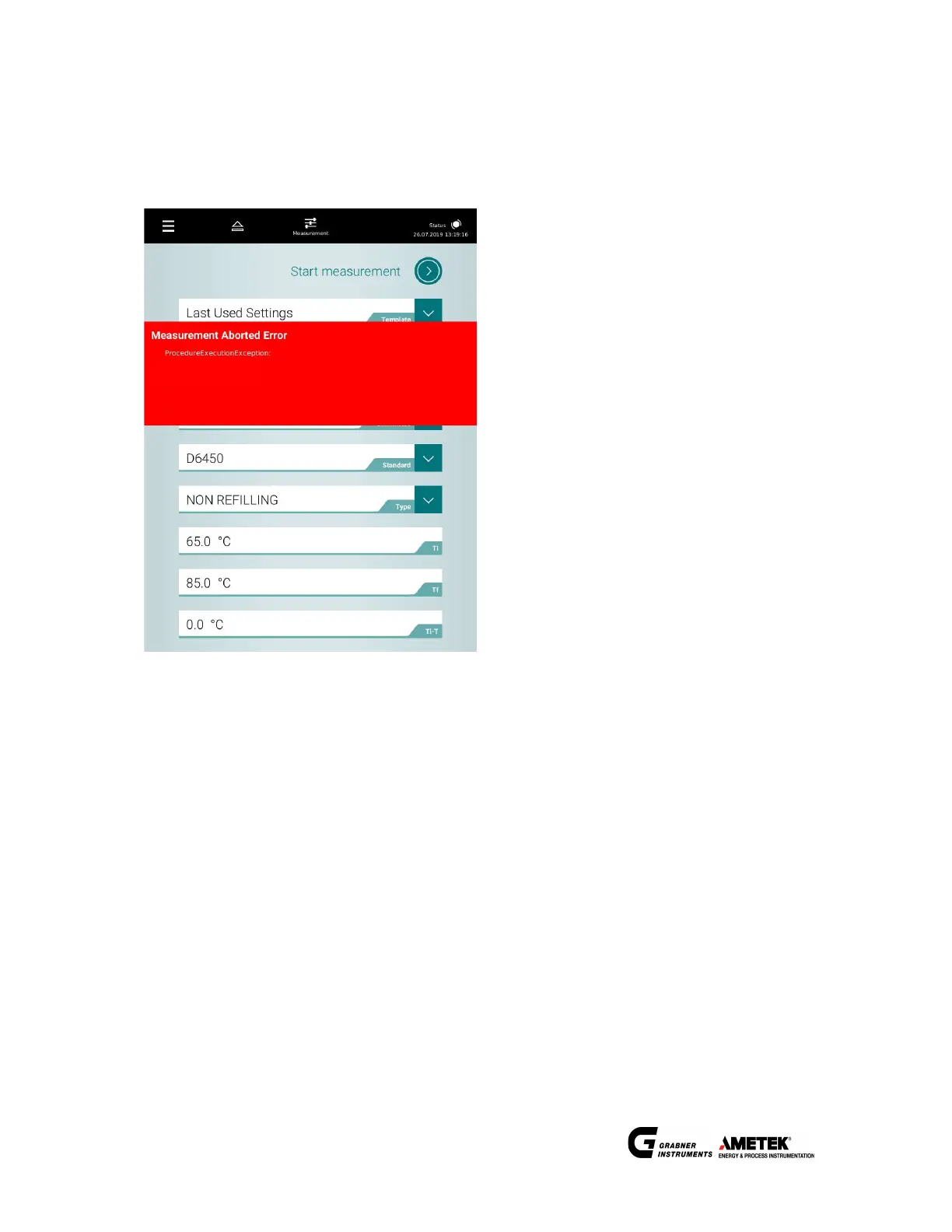

8.3 Start Temperature Adjustment (Ti-T)

If the initial temperature of the sample is near or below ambient temperature, a refrigerator is necessary to cool the

sample because the temperature of the sample has to be below the initial temperature to start the measuring

routine. Otherwise the instrument will report an error:

To be able to cool the sample well below the initial temperature before the measuring routine starts, the starting

temperature can be set up to 0-15°C or 0-27°F below the initial temperature.

By setting the Start Temperature Ti-T to >0, the analyzer starts to actively cool the sample prior to measurement. This

feature is primarily intended to be used for using MINIFLASH FP(H) VISION in the field, where no refrigerator is

available.

Example: Room temperature and sample temperature is 20°C and the test has to be started at 18°C. If you insert the

sample and press RUN, the instrument will report an error, as it is not actively cooling. If you set the Start

Temperature Ti-T to 5°C, the analyzer will cool the sample to 18-5 = 13°C and be able to start the measurement.

8.4 Pressure threshold adjustment p Limit (Custom Programs only)

The standard value 20.0 kPa for the pressure threshold detects flames that cover 50% to 90% of the surface with a

thickness of approx. 3 mm. This ensures reliable flash detection. A low limit for pressure increase degrades the

repeatability. For testing flashpoint according to standards, the pressure threshold for flashpoint tests must be 20 kPa.

If you are using the standard methods ASTM D6450 and ASTM D7094, the pressure threshold is locked to 20 kPa and

cannot be changed.

Loading...

Loading...