Page 65

Hardware

Slow scan CCD’s have relatively low bandwidth and hence can only be read out at modest speeds typically less than

1MHz. EMCCD cameras avoid this constraint by amplifying the charge signal before the charge amplier and hence

maintain unprecedented sensitivity at high speeds. By amplifying the signal the readout noise is effectively by-passed

and as such, EMCCD readout noise is no longer a limit on sensitivity (and can often be considered negligible).

Please see pages 23 & 24 for further details on EMCCD technology and sensor architecture.

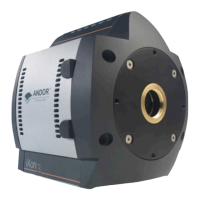

4.3 - VACUUM HOUSING

Unless protected, cooled CCD sensors will condense moisture, hydrocarbons and other gas contaminants that

will attack the CCD surface. If that happens, CCD performance will decline proportionally and will eventually fail.

Fortunately, the integrity of the sensor can be preserved by housing it in a protective enclosure. However, it is important

to understand that all such environments are not the same and the underlying technology used can seriously impact

camera life (and performance).

A permanent hermetic vacuum head is an essential component of high-end imaging and spectroscopy EMCCD

cameras. A permanent vacuum requires not only a hermetic seal, but also low outgassing. These criteria are what

Andor’s UltraVacTM vacuum process uniquely ensures. It is the low outgassing (see page 78) that is the real challenge

and, in reality, what sets the real limit on long-term performance. Andor has developed and utilized the UltraVacTM

process over more than 10 years, so it is proven with 1000’s of systems in the eld and a measured Mean-Time-

Between-Failure (MTBF) of 100 years; that means it will take 100 years for half of them to fail!

Furthermore, Andor’s rigorous, proprietary vacuum process is carried out in a Class 10,000 clean room; this

means less than 10,000 particles of less than 0.5 micron dimension per cubic meter. The air is fully replenished

every minute. We welcome visitors to inspect our state-of-the-art facility.

• Sustainedvacuumperformanceovermanyyearsoperation–proprietaryprocesstominimizeoutgassing.

• Benetfromathoroughlyprovensolution-UltraVacTM.10yearsofshippingvacuumsystemstotheeldanda

negligible failure rate (an MTBF of 100 years).

• Performanceimprovesbecausethetemperatureofthechipcanbereducedsignicantly.Bettercooling(down

to-100°CwithanenhancedthermoelectricPeltierdesign)translatesintosubstantiallylowerdarkcurrentand

fewer blemishes.

• SuchdarkcurrentperformanceisparticularlycriticaltoEMCCDtechnology,whereevenasinglethermal

electron is detected as a spurious noise spike.

• Eliminationofcondensationandoutgassingmeansthatthesystemcanalsouseonlyasingleentrancewindow,

withantireectioncoating–youcanbelievetheQEcurve.

• Thepermanenthermeticvacuumensuresthatpeakquantumefciencyandcoolingwillnotdegrade,evenafter

years of operation.

Loading...

Loading...