Page 66

Hardware

4.3.1 - Thermoelectric cooler

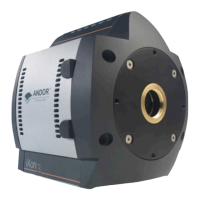

TheiXon3rangemakesuseofafour-stage(seeNOTEbelow),Peltiercoolingassembly,whichutilizesthethermoelectric

effect to rapidly cool the sensor down to the stable operating temperature. TE coolers have a cold end (in contact with

the sensor) and a hot end. Heat must be efciently dissipated from the TE cooler for effective cooling of the sensor.

The iXon3 is expertly designed to yield maximum heat dissipation, via either forced air cooling (in-built fan) or water

cooling, which in combination with Andor’s UltraVacTM vacuum process, results in market-leading cooling performance.

A recirculator or a chiller can be purchased from Andor Technology to provide convenient and effective heat dissipation

through water cooling.

The iXon3 camera also contains temperature control components, which regulate the cooling of the camera and ensure

that a stable temperature is maintained between and throughout measurements.

NOTE: DV885 models have a three-stage peltier cooler; DU885 models have a four-stage peltier cooler.

4.4 - OUTGASSING

Outgassingisthereleaseofagastrappedinmaterial.Itisaproblemencounteredinhigh-vacuumapplications.

Materials not normally considered absorbent can release enough molecules to contaminate the vacuum and cause

damage to optical sensors, window coatings, etc.

Even metals and glasses can release gases from cracks or impurities, but sealants, lubricants, and adhesives are the

most common cause. Left unchecked, cooling performance would steadily degrade and therefore lead to increased dark

current. Furthermore, resulting electrochemical reactions would eventually destroy the sensor.

Figure 44: UltravacTM metal

hermetic vacuum sealing

Loading...

Loading...