16 02.A.003

7. ASSEMBLY

7.1. General recommendations

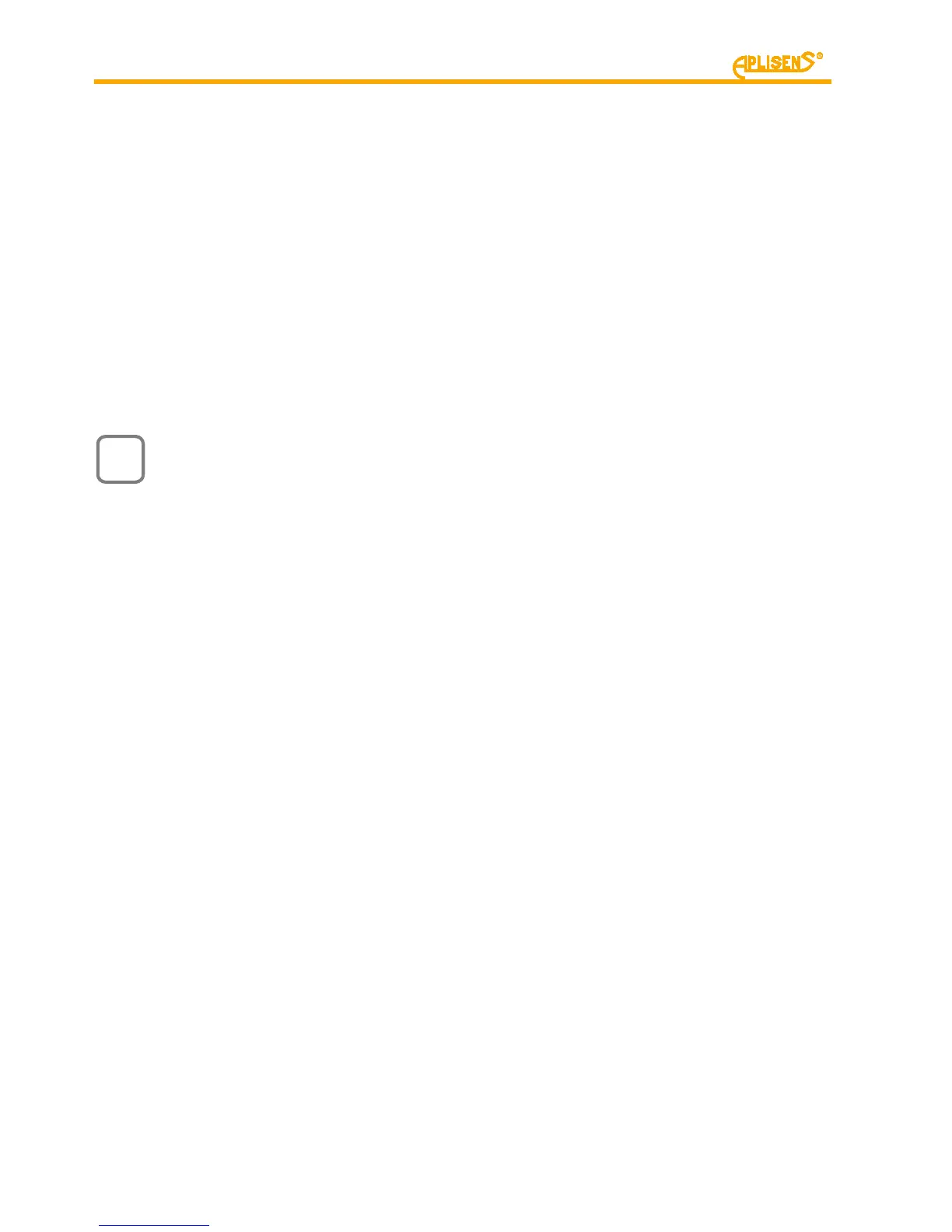

Sensor of the electromagnetic flowmeter can be installed in any position in

accordance with the requirements but in case of vertical installation axis of

the electrodes should be always horizontal.

Entire space inside the sensor should be filled with the measured liquid during

the measurements.

It is recommended to ensure that direction of flow is consistent with direction of

the arrow on cover of the sensor; converter is factory set for operation in

this direction. It is possible to reverse direction of flow on operating device but

then also direction of flow in converter parameters should be changed.

It needs to be checked before the assembly whether there is enough space at

the flange to mount the flow meter using the available screws and nuts.

To avoid the influence on the vibration measurement as well as on the deflection

installation, the piping system must be fixed on both sides of the flow meter.

If the flow meter is installed on the pipeline with an greater inside diameter,

a reducer must be applied to ensure the axial fastening without the increase of

stress in pipes and flanges of the sensor.

During installation the straight sections should be of nominal diameter of

the sensor (DN) with lengths of at least 5DN before and 3DN after the sensor.

When installing the sensor on an insulated pipe (e.g. glass, plastics etc.) please

insulate the system with earthing rings connected with ground terminal of

the sensor - (fig. 15).

Conductive connection between ground (enclosure) of the sensor and liquid is

necessary for correct measurements.

It is essential to assemble the seal on both sides of the earthing ring during

the installation. It must be ascertained that no element of the seal is not included

in the clearance of the pipeline, as it may generate turbulence and disturb

the flow meter operation.

Loading...

Loading...