8 02.A.003

water management, the measurements of drinking water and wastewater,

the chemical, textile, paper industries as well as mining,

the food industry,

energy and heating installations,

agriculture.

The converter processes the measuring signal from the measuring sensor into

the 4...20 [mA] signal and Modbus RTU/RS 485.

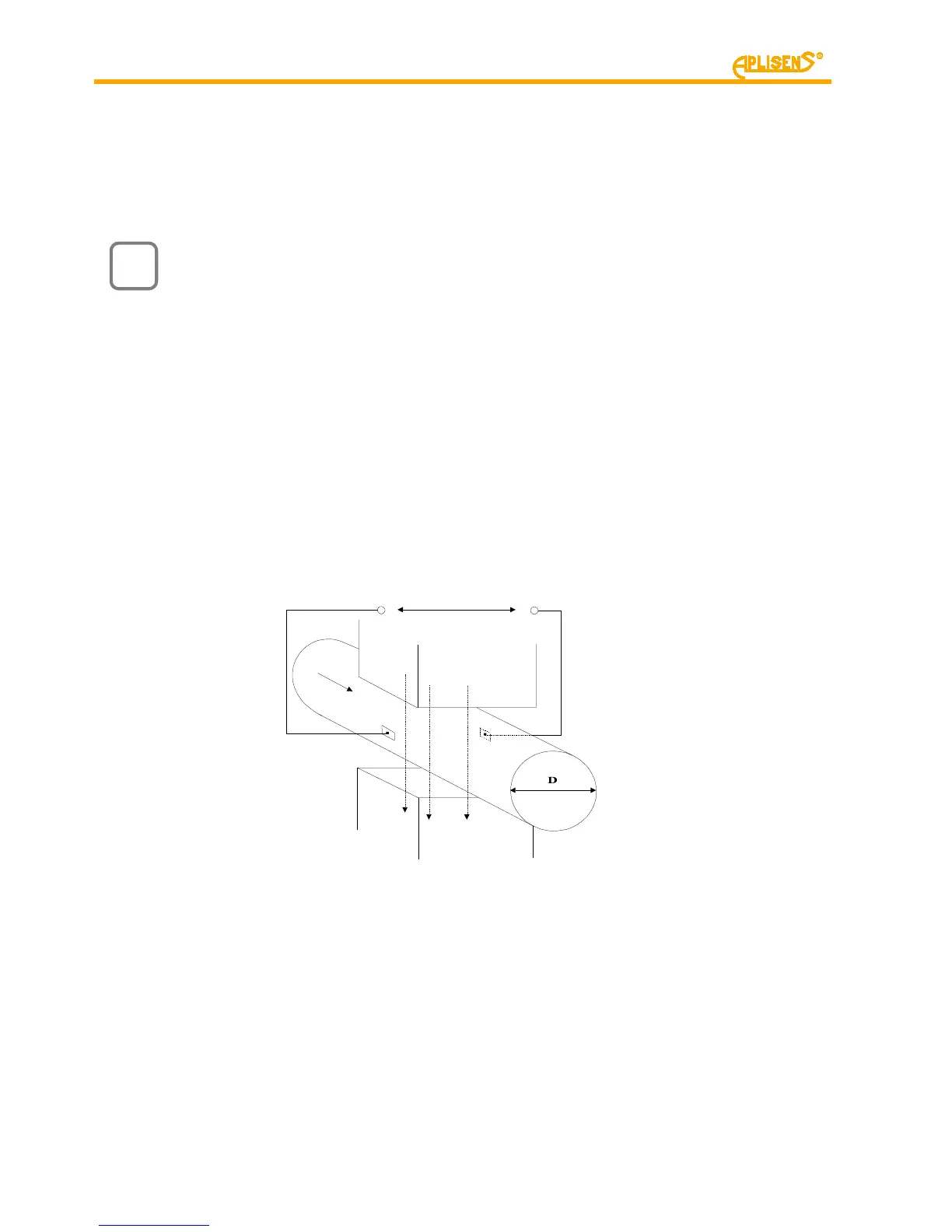

6.2. The operating principle

The measurement flow uses the phenomenon of electromagnetic induction. In accordance

with the law of Faraday the conductor moving in the magnetic field induces the electrical

voltage. To designate the induced voltage the following equation is applied:

U=B x D x v

where:

U – induced voltage

v – the average flow velocity vector

D – diameter of the pipe

B – magnetic flux density

If magnetic flux density B and the pipe diameter D are constant the induced voltage is

proportional to the average flow velocity. The fluid flows through the flow meter

perpendicularly to the magnetic field. The electrical voltage, which is controlled by two

electrodes, placed at right angles to both the magnetic field and the flow, is induced by the

stream of the electrical conductive fluid. The excitation of the rectangular-wave shape current

is generated in the converter and fed to the spool coils of the measuring sensor, producing

the magnetic field of the flow meter. The power supply provides the coil with constant

excitation in all working condition of the flow meter.

Loading...

Loading...