Ascon Tecnologic - X34 - OPERATING INSTRUCTIONS - PAG. 19

the RTC, the key action has priority on the event.

4 Pressing the key for at least 1 s activates/deactivates a

Turbo cycle.

5 Forces a programmed Switch-ON/Switch-OFF (Stand-

by) event - Pressing the key for at least 1 s switches the

instrument from the ON state to the Stand-by state and

vice-versa, until the next event. Therefore, if switch-ON/

Stand-by events are programmed using the RTC, the key

action has priority on the event.

6 HACCP Alarm Reset - Pressing the key for at least 1 s

resets stored HACCP alarms. The display confirms the

reset showing “---” for about 1 s.

7

HACCP Alarm Recording Disabled - Pressing the key for at

least 1 s disables/enables recording of the HACCP alarms.

After the selection is made the display shows for about 1 s:

Hon (HACCP alarms enabled) or

Hof (HACCP alarms disabled).

5.13 Clock programmable events

Programmable events are set using the 14 parameters

(c.01... c.14) contained in the

]

cE group.

After selecting the desired parameter, press the

key re-

peatedly to cycle through the following:

h..

oo

Hours (e.g. h.13);

n..

oo

Minutes (e.g. n.45);

d..

o

Day of the week (e.g. d.1);

t.

o

Type of event to be performed at the programmed time

(e.g. t.1).

Note: See “2.8 Scheduling events at defined times” a pagina

5 for details.

The days are numbered as follows:

d. 1 Monday;

d. 2 Tuesday;

d. 3 Wednesday;

d. 4 Thursday;

d. 5 Friday;

d. 6 Saturday;

d. 7 Sunday;

d. 8 every day;

d. 9 Monday, Tuesday, Wednesday, Thursday, Friday;

d.10

Monday, Tuesday, Wednesday, Thursday, Friday, Saturday;

d.11 Saturday and Sunday;

d.oF No day (event disabled).

The 14 event-programming parameters allow a maximum of

14 x 7 = 98 weekly events to be scheduled (using d. 8).

The following events can be programmed:

t.1 Switch instrument ON;

t.2 Put instrument in Stand-by;

t.3 Switch auxiliary output ON;

t.4 Switch auxiliary output OFF;

t.5 Start defrost (to enable scheduled defrosting, also

program d.dC = cL);

t.6 Switch to Eco mode (SPE);

t.7 Switch to normal mode (SP).

A manual intervention, e.g. to change the mode (Eco or Nor-

mal) or activate/deactivate the auxiliary output, is effective

only until the next scheduled event.

For example, if the instrument is in Eco mode and is forced

manually to Normal mode it will stay in Normal mode until

the next event that switches it to Eco mode.

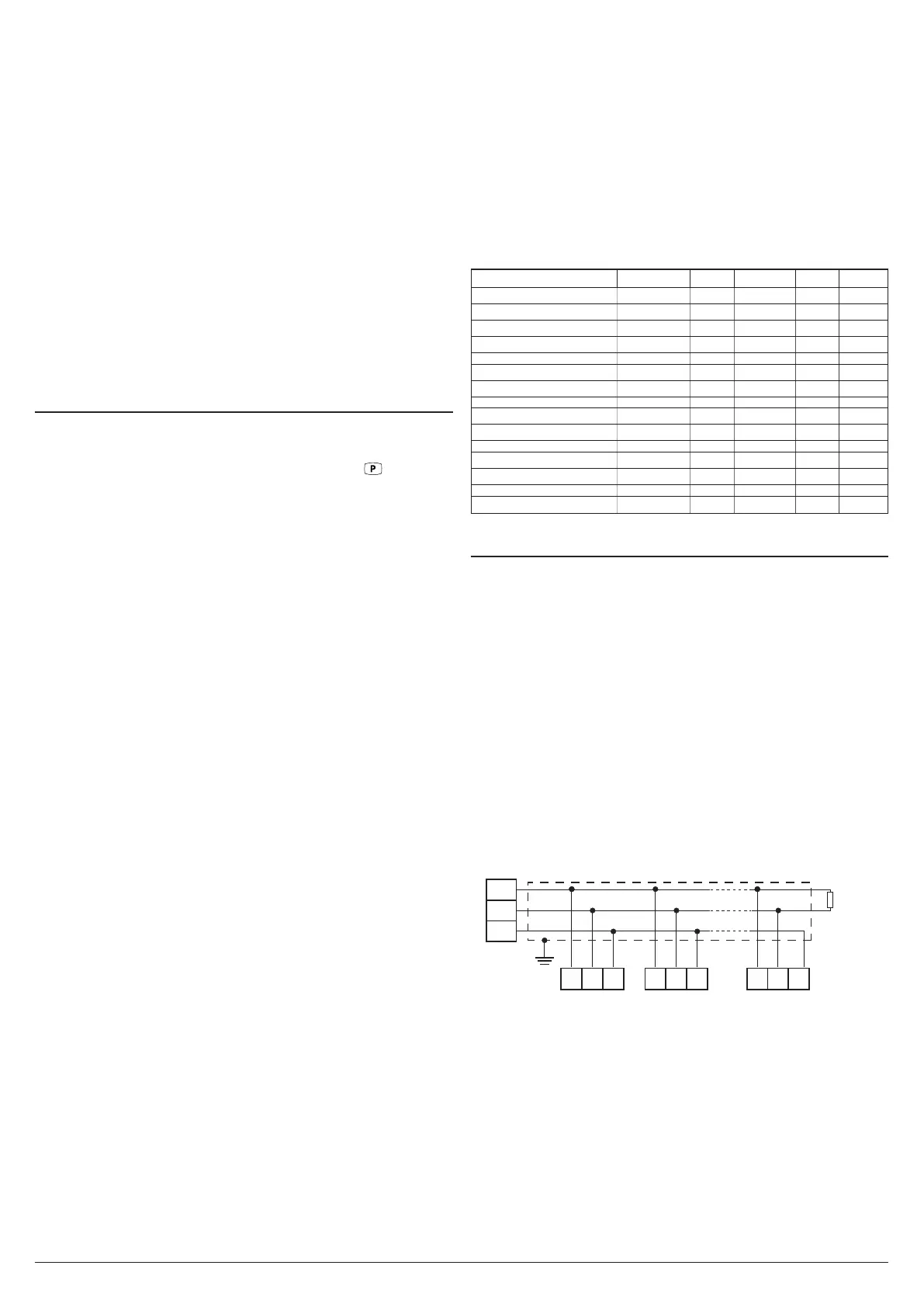

Programming example

The user wishes to set the following events:

– 4 daily defrosts weekdays at 7:00, 12:00, 17:00 and 22:00;

– 2 defrosts every Sunday at 7.00 and 19.00

(also set d.dC = cL);

– 1 daily weekday switching from Normal to Eco mode at

20.00 and 1 switching from Eco to Normal mode at 6.00;

– No switches on Sundays;

– 1 daily weekday switching Aux output ON at 8.00 and

1 daily switching the Aux output to OFF at 21.00;

– No switches on Sundays.

Event Parameter Hour Minutes Days Event

Work day defrost 1

c.01 h.07 n.00 d.10 t.5

Work day defrost 2

c.02 h.12 n.00 d.10 t.5

Work day defrost 3

c.03 h.17 n.00 d.10 t.5

Work day defrost 4

c.04 h.22 n.00 d.10 t.5

Sunday defrost 1

c.05 h.07 n.00 d.7 t.5

Sunday defrost 2

c.06 h.19 n.00 d.7 t.5

ECO mode

c.07 h.20 n.00 d.10 t.6

Nomal mode

c.08 h.06 n.00 d.10 t.7

Aux on

c.09 h.08 n.00 d.10 t.3

Aux off

c.10 h.21 n.00 d.10 t.4

c.11...... c.14

h.00 n.00 d.oF t.oF

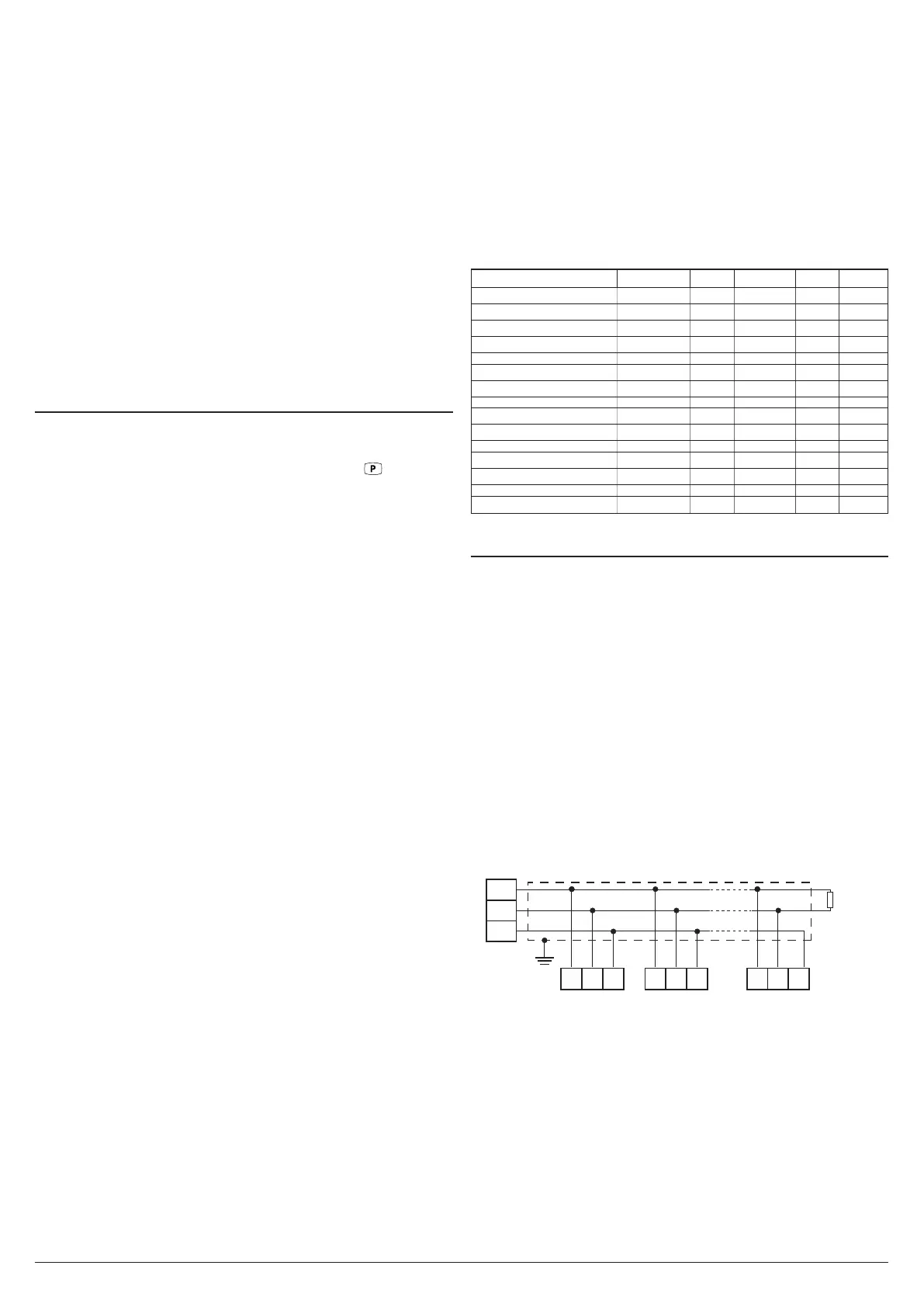

5.14 RS485 Serial Intefarce

The instrument can be equipped with a RS485 serial com-

munications interface, by means of which it is possible to

connect the controller to a network to which other instru-

ments (PLC controllers) are connected, all depending typi-

cally on a personal computer used as plant supervisor.

Using a Personal Computer it is possible to acquire all

the function information and to program all the instrument

configuration parameters. The software protocol adopted fa

MODBUS RTU type, widely used in several PLC and super-

vision programs available on the market (X34 series protocol

manual is available on request).

The instrument has two terminals called D+ and D- that must

be connected to all network terminals with the same label.

For wiring the line, it is advisable to adopt a 3-pole wired and

shielded cable connected as shown.

D+

D-

GND

(OP/PC/PLC)

RS485

Interface

shield

14

Rt

120Ω

15 16

D+ GNDD-

X34 no. 1

14 15 16

D+ GNDD-

X34 no. 2

14 15 16

D+ GNDD-

X34 no. 31

The interface circuit allows the connection of up to 32 instru-

ments on the same line.

To maintain the line in rest conditions a 120

W

resistance (Rt)

must be connected to the end of the line.

If the instrument is equipped with a serial interface, the pa-

rameters to be programmed are those present at parameters

group ]tS:

t.AS Address of the station. Set a different number for

each station, from 1 to 255.

t.br Serial interface baud rate. Settings available:

1 = 9600 baud, 2 - 19200 baud, 3 - 38400 baud.

Loading...

Loading...