What does it mean if the “Broken Gage Bit” is set on ATI Technologies Axia80-M8?

- SStephanie WiseSep 7, 2025

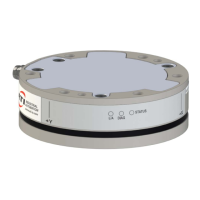

If the “Broken Gage Bit” is set, it suggests a potential electrical failure inside the ATI Technologies sensor. In this case, the sensor must be returned to ATI for diagnosis.