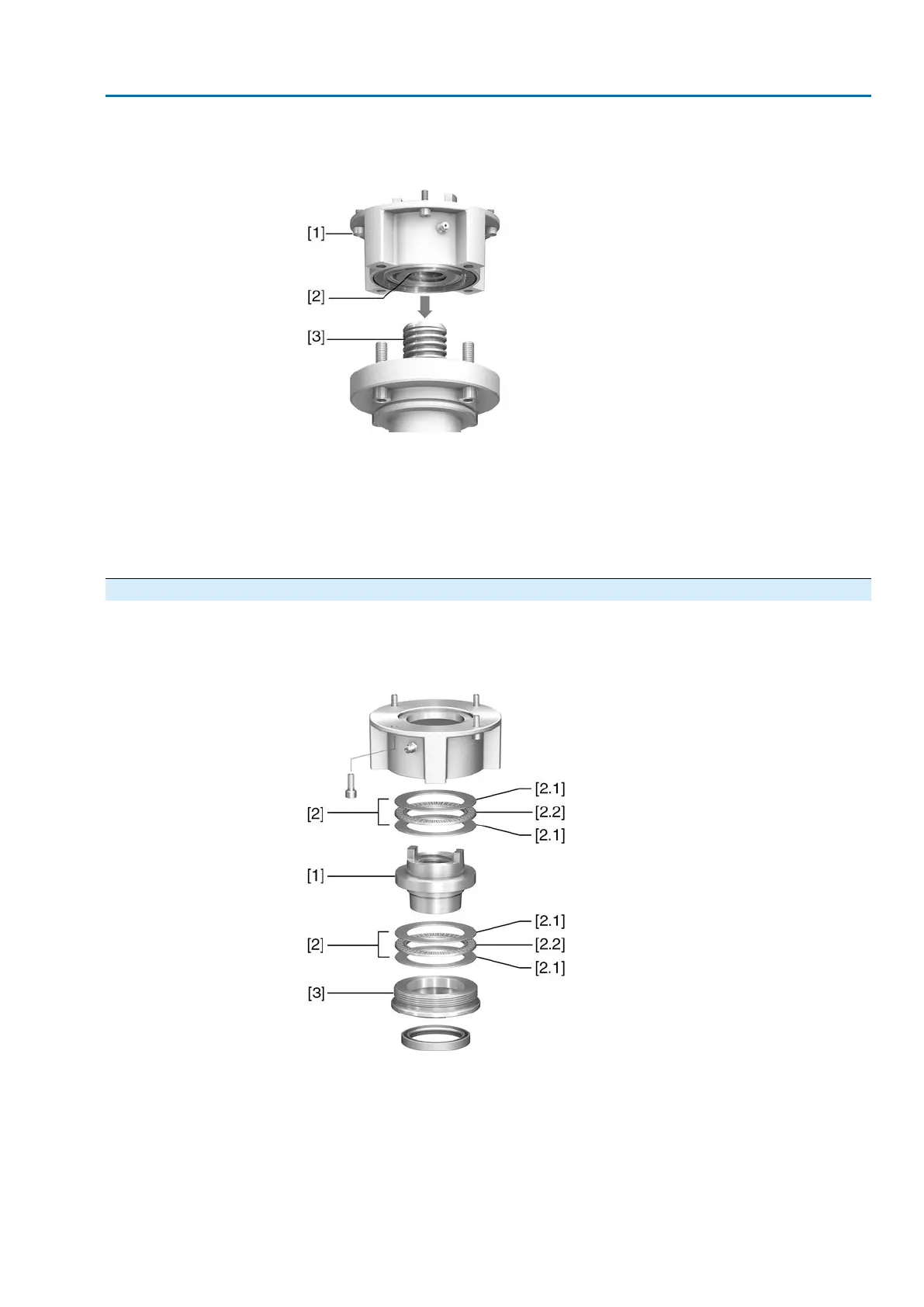

Design

Output mounting flange [1] with axial bearing stem nut [2] form one unit.Torque is

transmitted to valve stem [3] via stem nut [2].

Figure 9: Design of output drive type A

[1] Output mounting flange

[2] Stem nut with dog coupling

[3] Valve stem

Information

To adapt the actuators to available output drive types A with flanges F10 and F14

(year of manufacture: 2009 and earlier), an adapter is required. The adapter can be

ordered from AUMA.

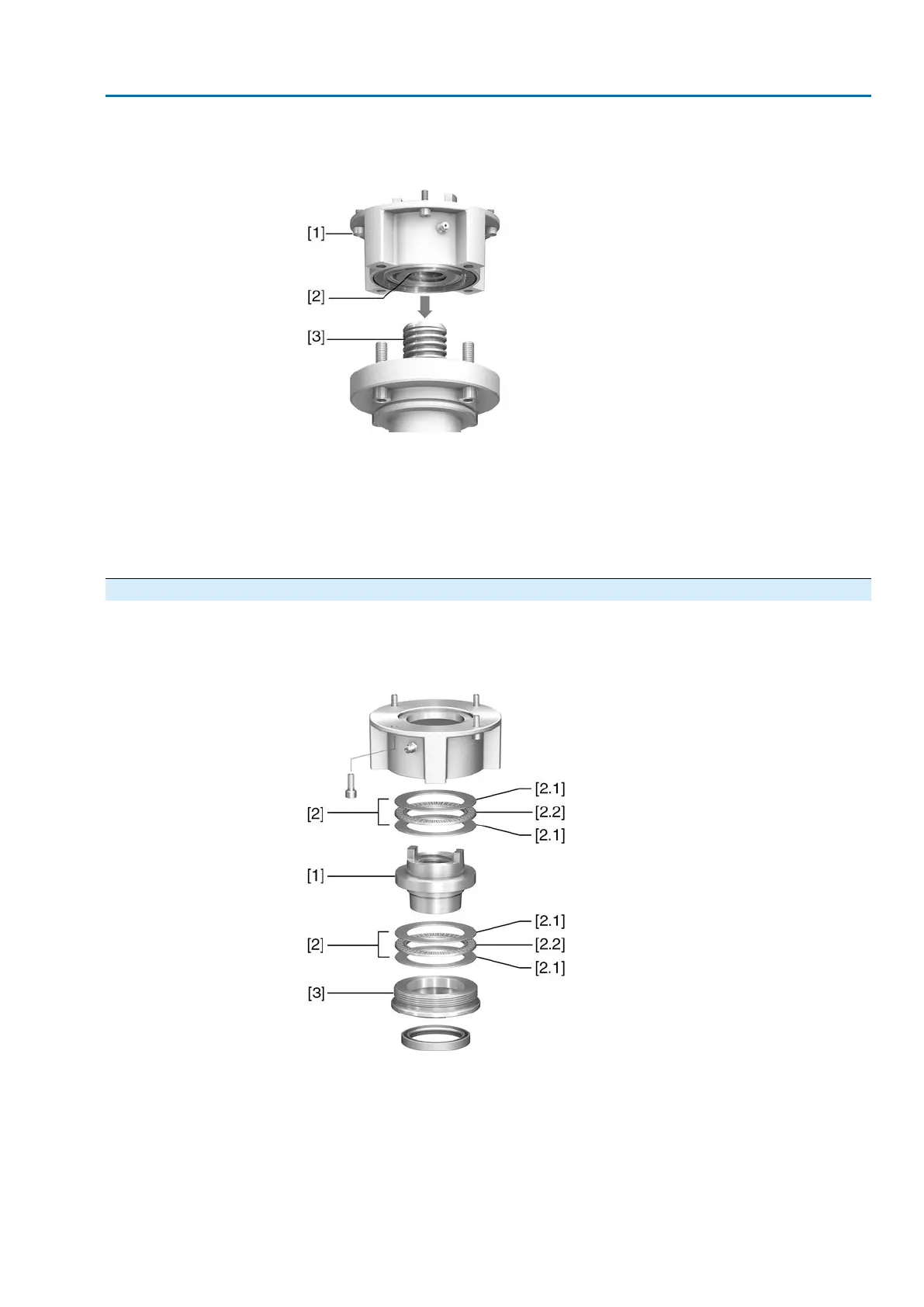

4.3.1.1. Stem nut: finish machining

✔

This working step is only required if stem nut is supplied unbored or with pilot

bore.

Figure 10: Output drive type A

[1] Stem nut

[2] Axial needle roller bearing

[2.1] Axial bearing washer

[2.2] Axial needle roller and cage assembly

[3] Spigot ring

1. Remove spigot ring [3] from output drive.

2. Remove stem nut [1] together with axial needle roller bearings [2].

17

SAV 07.2 – SAV 16.2 / SARV 07.2 – SARV 16.2 Control unit: electronic (MWG)

ACV 01.2 Modbus TCP/IP Assembly

Loading...

Loading...