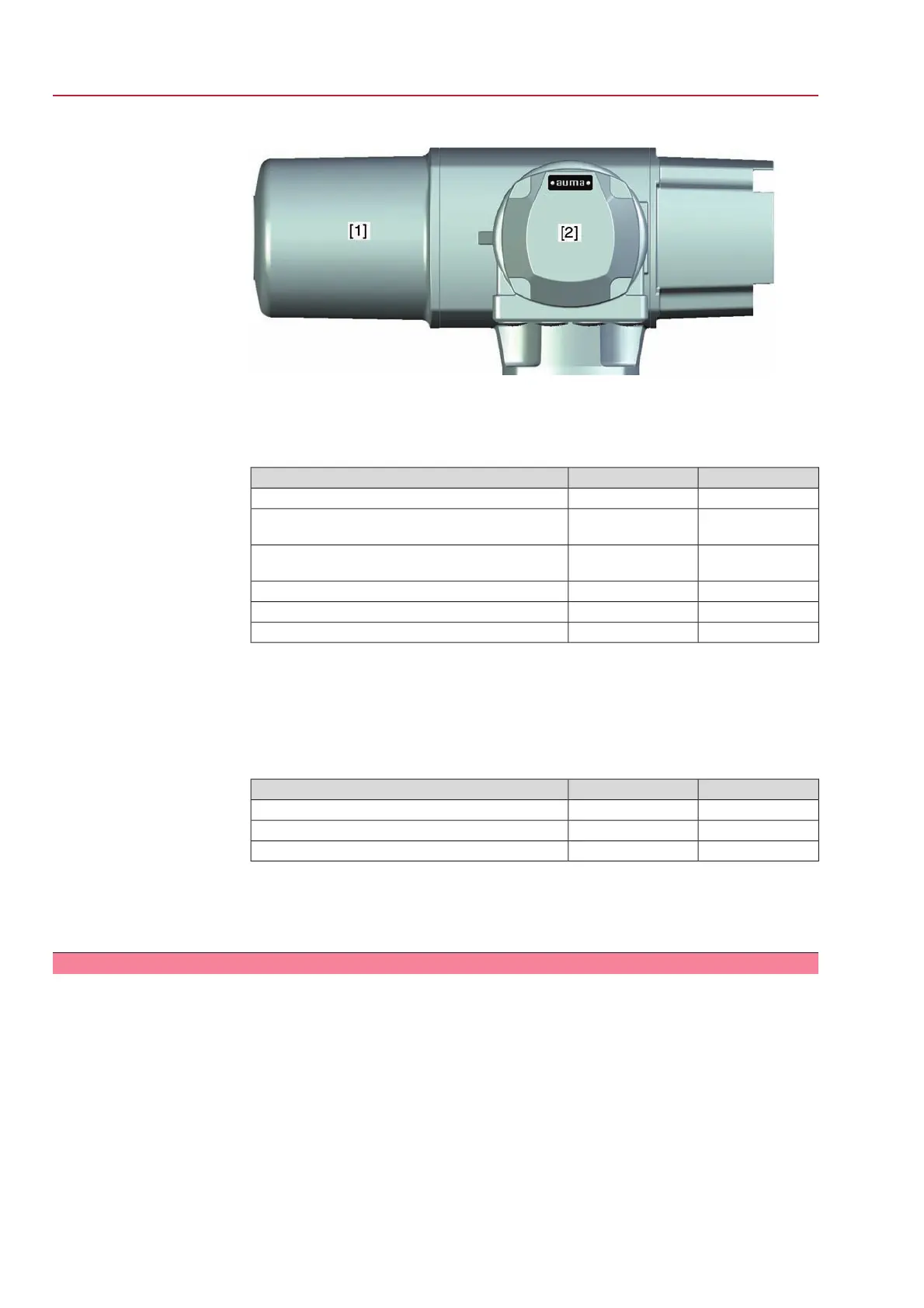

Figure 58: Access to fuses

[1] Rear cover

[2] Electrical connection

F1/F2

Primary fuses on power supply unit

AUMA Art. No.:F1/F2G fuses

6.3 x 32 mmSize

K002.2771 A T; 500 VReversing contactors

Power supply 싨 500 V

K002.6652 A FF; 660 VReversing contactors

Power supply > 500 V

K001.18516 A FF; 500 VThyristor units for motor power up to 1.5 kW

K006.96530 A FF; 500 VThyristor units for motor power up to 3.0 kW

K002.2771 A T; 500 VThyristor units for motor power up to 5.5 kW

F3

Internal 24 V DC supply

F4

Internal 24 V AC supply (115 V AC) for:

●

Heater, switch compartment, reversing contactors control

●

PTC tripping device

●

for 115 V AC also control inputs OPEN - STOP - CLOSE

F4F3G-fuse according to IEC 60127-2/III

5 x 20 mm5 x 20 mmSize

1.25 A T; 250 V1.0 A T; 250 VVoltage output (power supply unit) = 24 V

0.315 A T; 250 V1.0 A T; 250 VVoltage output (power supply unit) = 115 V

F5

Automatic reset fuse as short-circuit protection for external 24 V DC supply for

customer (see wiring diagram)

Information After fuse replacement, replace and fasten cover.

10.3.2 Motor protection (thermal monitoring)

In order to protect against overheating and impermissibly high temperatures at the

actuator, PTC thermistors or thermoswitches are embedded in the motor winding.

The thermoswitch is tripped as soon as the max. permissible winding temperature

has been reached.

The actuator is switched off and the following signals are given:

●

LED 3 (thermal fault) on the local controls is illuminated.

●

Status indication S0: Operation mode OFF/LOCAL = FLT + NR

●

Status indication S0/S6: Operation mode REMOTE = FAULT IND.

●

Status indication S1: THERMAL FAULT

The motor has to cool down before the operation can be resumed. Depending on

the parameter setting, the fault signal is either automatically reset or the fault signal

has to be acknowledged.

60

SG 05.1 – SG 12.1/SGR 05.1 – SGR 12.1 Control unit: electromechanic

Corrective action AC 01.1 Intrusive Modbus RTU

Loading...

Loading...