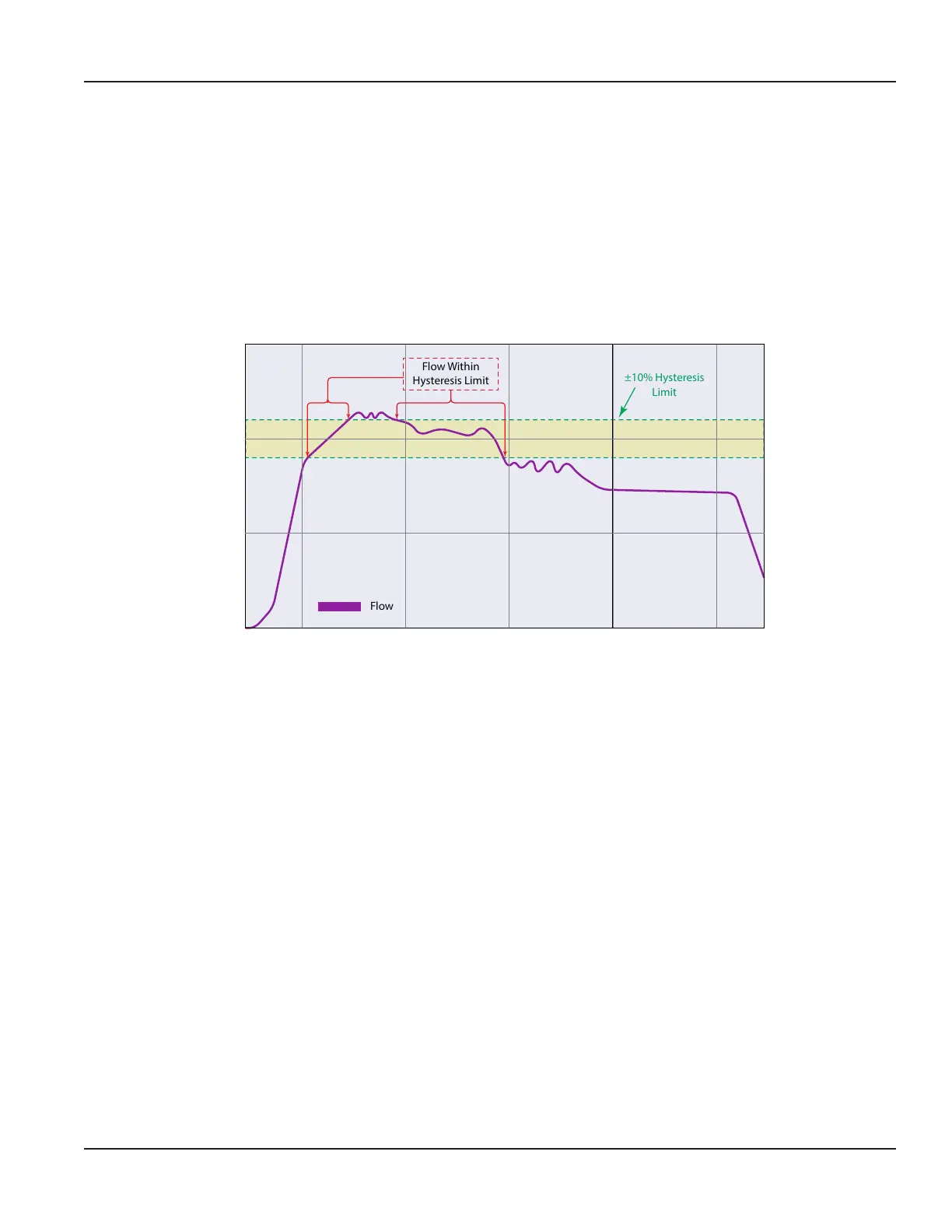

For example, if the average flow rate is 100 gpm and the Hysteresis is set to 10%, a filter window of 90…110 gpm is

established. Successive flow measurements that reside within that window are recorded and averaged in accordance with

the Damping setting. Flow readings outside of the window are rejected or accepted in accordance with the

Bad Data Rejection setting.

Filter settings for this example:

Filter Method Adaptive

Damping 40 seconds

Sensitivity 60%

Hysteresis 10%

Bad Data Rejection 3

Flow Within

Hysteresis Limit

±10% Hysteresis

Limit

Flow

150

100

50

0

110

90

Figure 38: Hysteresis window

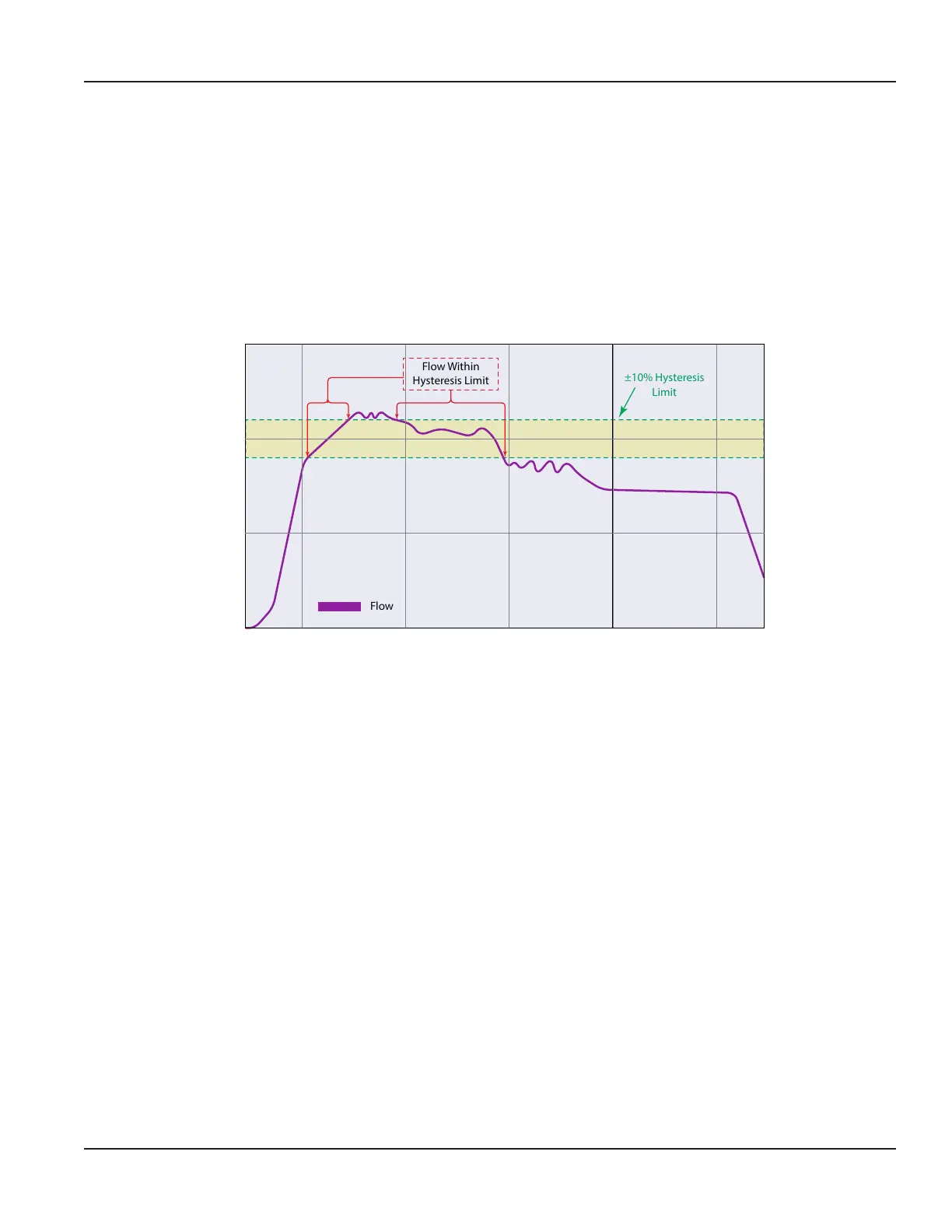

Bad Data Rejection (Range 0…10 Samples; Default: 3)

The Bad Data Rejection setting is related to the number of successive readings that must be measured outside of a the

Hysteresis value before the flow meter considers the new flow value valid. In this example, a Hysteresis setting of 10% produces

a ± 10% band centered on the current valid flow rate of 100 gpm.

The Bad Data Rejection setting is the number of successive samples that must be outside of the Hysteresis window before

the flow meter considers the change in flow as real. Larger values are entered into the Bad Data Rejection window when

measuring liquids that contain gas bubbles, as the gas bubbles tend to disturb the ultrasonic signals and cause more

extraneous flow readings to occur. Larger Bad Data Rejection values tend to make the flow meter less responsive to rapid

changes in actual flow rate.

In Figure 40 on page 30, flow data falls outside the flow Hysteresis window but does not reach the minimum time specified in

the Bad Data Rejection window. When data appears that is outside the Hysteresis band and shorter than the Bad Data Rejection

window time, the data is rejected.

Parameter Descriptions by Menu

Page 29 October 2019 TTM-UM-02222-EN-04

Loading...

Loading...