WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

Overview

The D10 Expert Small Object Counter sensor is a high-performance plastic

fiber optic amplifier that has been optimized for small object counting

using through-beam fiber optic arrays. Fiber optic arrays emit and receive

light over an area instead of a narrow beam. Having an area of light

makes alignment and positioning control of the object less critical than

using single point emitter and receiver fiber optic assemblies. Because the

object only breaks part of the fiber optic array, reliable detection requires

very precise thresholds, an auto compensation tracking algorithm, and

high speed electronics to make split-second decisions.

The setup and configuration of the advanced D10D sensor has been

reduced to the act of applying power to the device with the fiber optic

assemblies rigidly mounted in position. The user also has access to a

comprehensive collection of setup and configuration parameters through

the sensor’s advanced setup menu, but for most applications the default

options provide superb performance and reliability.

Upon power-up, the clear-state light level is measured and appropriate

switching thresholds are established, making the fiber optic sensor

system a stable, fast, and reliable small object counter. The clear-state

light level can be reset by performing a 2 second hold on the dynamic (+)

push button or single-clicking the remote line.

Continued reliable operation is ensured as the thresholds adapt to

changing signal levels over time using Banner Engineering’s auto

compensation tracking algorithm. The sensor continuously tracks the

clear-state light level and makes fine adjustments to the switching

thresholds as required because of dust or contamination building up on

the fiber optic array and for ambient temperature changes.

The sensor features either two NPN or two PNP outputs, depending on

your model. Each output serves a different purpose. The discrete output 1

(white wire) switches whenever an object breaks the fiber optic array and

can be used for counting. The Health Mode output 2 (black wire) switches

when the fiber optic array becomes contaminated to a point that the auto

compensation tracking algorithm cannot sufficiently adjust the thresholds

to ensure reliable detection (see Health Mode Alarm on page 3).

The duration of the discrete output 1 (white wire) can be increased

(stretched) to ensure accurate counting. The amount of increase is a user

configurable percentage of the detection event duration; the default

increase time is 50% more than the event duration. Banner calls this

feature a Dynamic Event Stretcher (DES), and it prevents errant double

counts of translucent gel-caps and other small objects of that type. The

DES provides a “smart” OFF-delay that is independent of application

speed and can be adjusted from 0% to 100% of the detection event

duration.

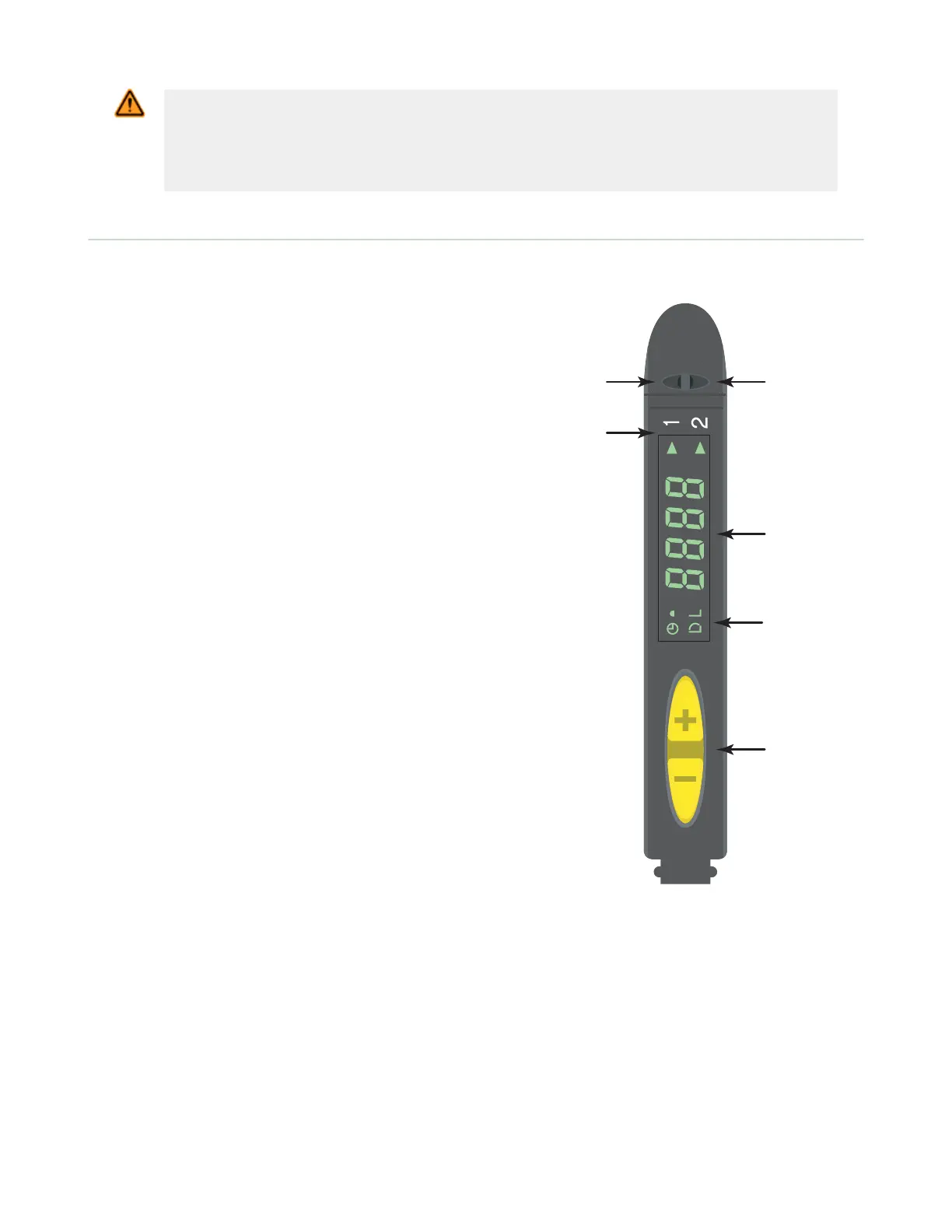

Figure 1. D10D Features

1. Counting output indicator

2. Arrow icons

3. Health mode output indicator

4. 4-digit display

5. Light/dark operate, clock, and lock

icons

6. Programming push buttons

D10 Expert Series - Small Object Counter

2 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 146132 Rev. D

Loading...

Loading...