Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

77

① Apply some molybdenum disulfide paste on the intake and exhaust valve stems evenly, and

assemble the intake and exhaust valves into the cylinder head, ensuring that the intake and

exhaust valves slide in the guide, without blockage;

② Assemble the lower seat of intake valve spring. Put the protective sleeves in the valve guides.

Assemble the valve stem seal.

Notice: Before assembling, must check whether the internal spring in the sealing bush of the

valve stem is kept intact.

③ Assemble the valve inner and outer springs.

④ Assemble the upper retainer for the valve spring. Press the valve spring in place. Assemble the

valve collet.

⑤ After assembly of the valve collets, tap the intake and exhaust valves using a rubber hammer so

that the valve collets come in close contact with the upper retainers for the valve springs. If the

valve collets fail to come in contact with the upper retainers for the valve springs, identify then

disassemble the causes.

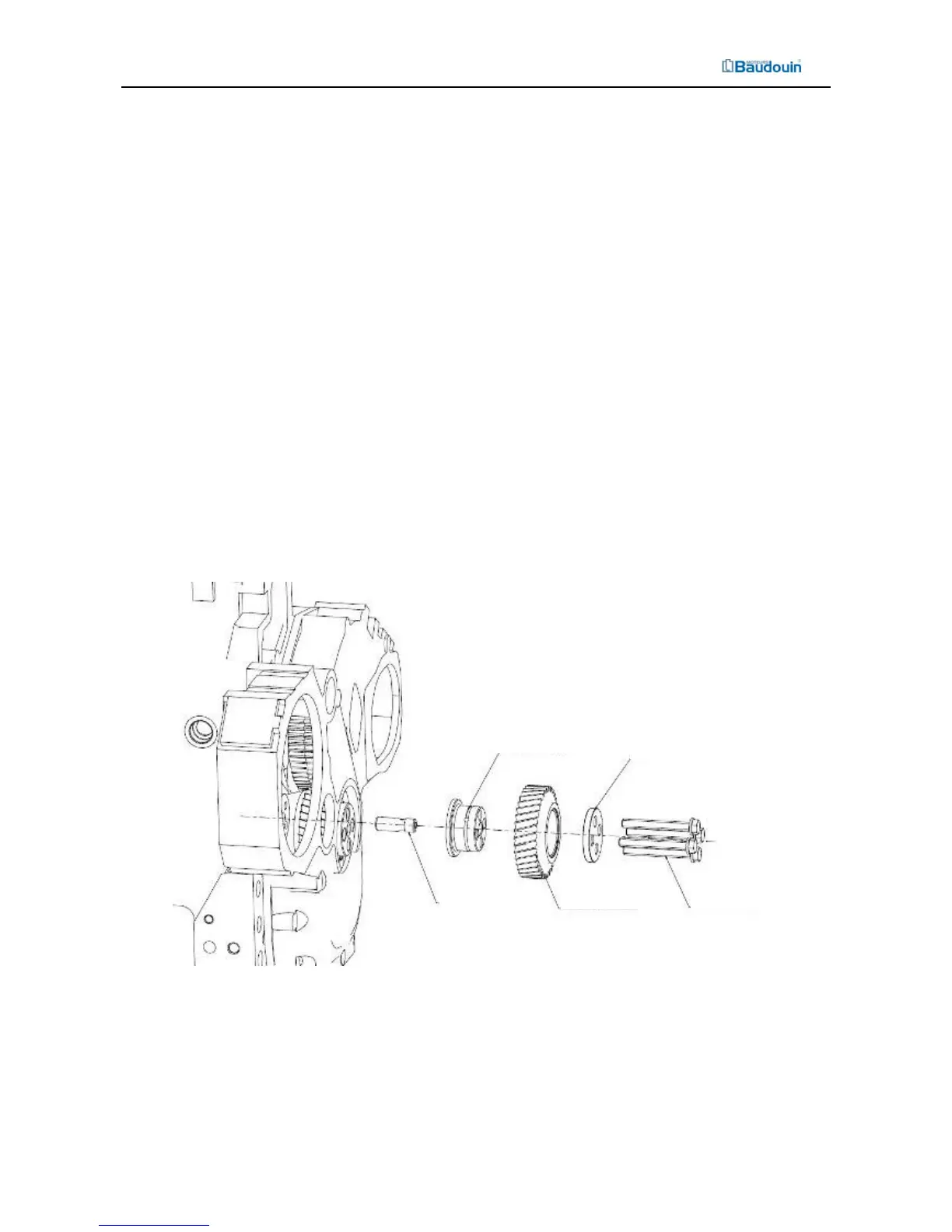

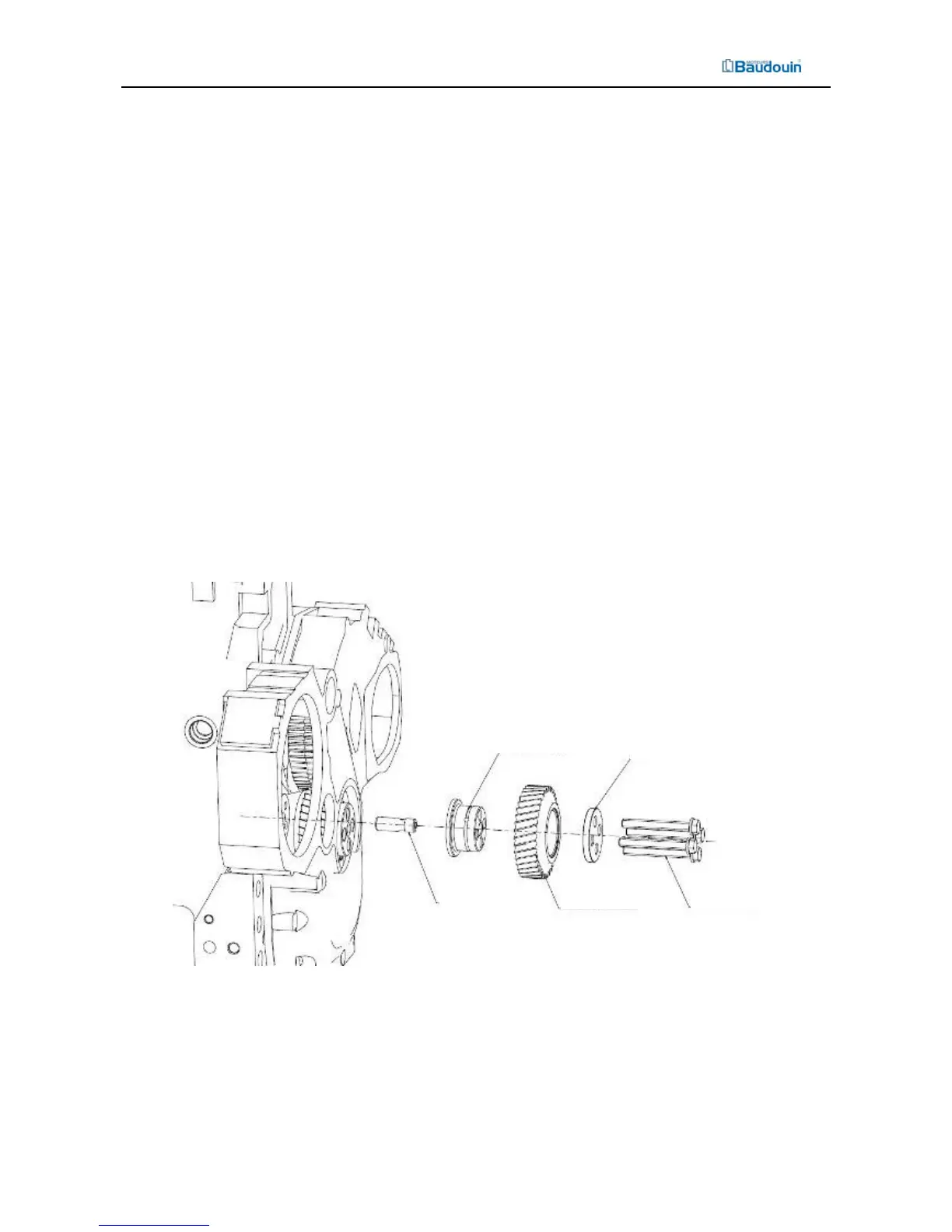

4.5.6 Disassembly, Inspection, Repair, and Assembly of Intermediate Gear

4.5.6.1 Exploded View for Assembly of Intermediate Gear

Figure 4-43 Exploded View for Assembly of Intermediate Gear

4.5.6.2 Intermediate Gear DisassemblyProcedures

① Observe the markings of mounting bolts and determine whether the bolts can rotate.

② Disassemble the four M10 hexagon bolts used for fixing the intermediate gear. Disassemble the

washer.

Intermediate gear shaft

Fender

Shaft Intermediate gear part Hexagon bolt

Loading...

Loading...