Maintenance Manual of 4M11 Series Diesel Engine For Land Power Generators

90

② Disassemble the connecting nuts between high pressure fuel pipe and various cylinders of fuel

injection pump in turn.

4.7.3.3 Inspection and Maintenance of High-pressure Oil Pipe

①Observe the external surface of high pressure fuel pipe for presence of cracking and leakage. If yes, replace

high pressure fuel pipe and feed back as per corresponding procedure.

②Observe the connector cones on two ends of high pressure fuel pipe and ensure the intactness.

4.7.3.4 High-pressure Oil Pipe Assembly Procedures

The assembly procedures are in the reverse order of the disassembly procedures. However, notice to

keep the high pressure fuel pipe clean and intact.

4.7.4 Disassembly, Inspection, Repair, and Assembly of Fuel Injector

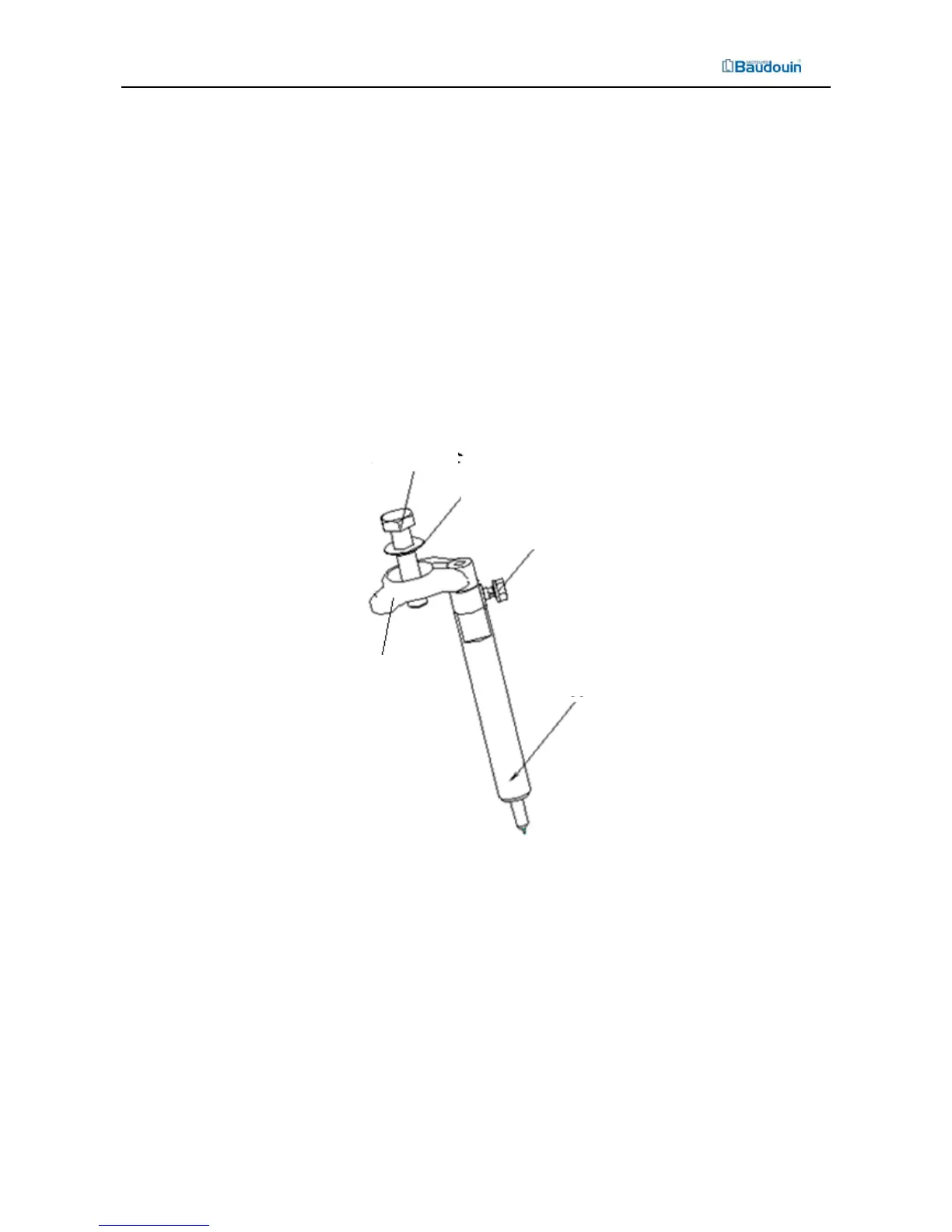

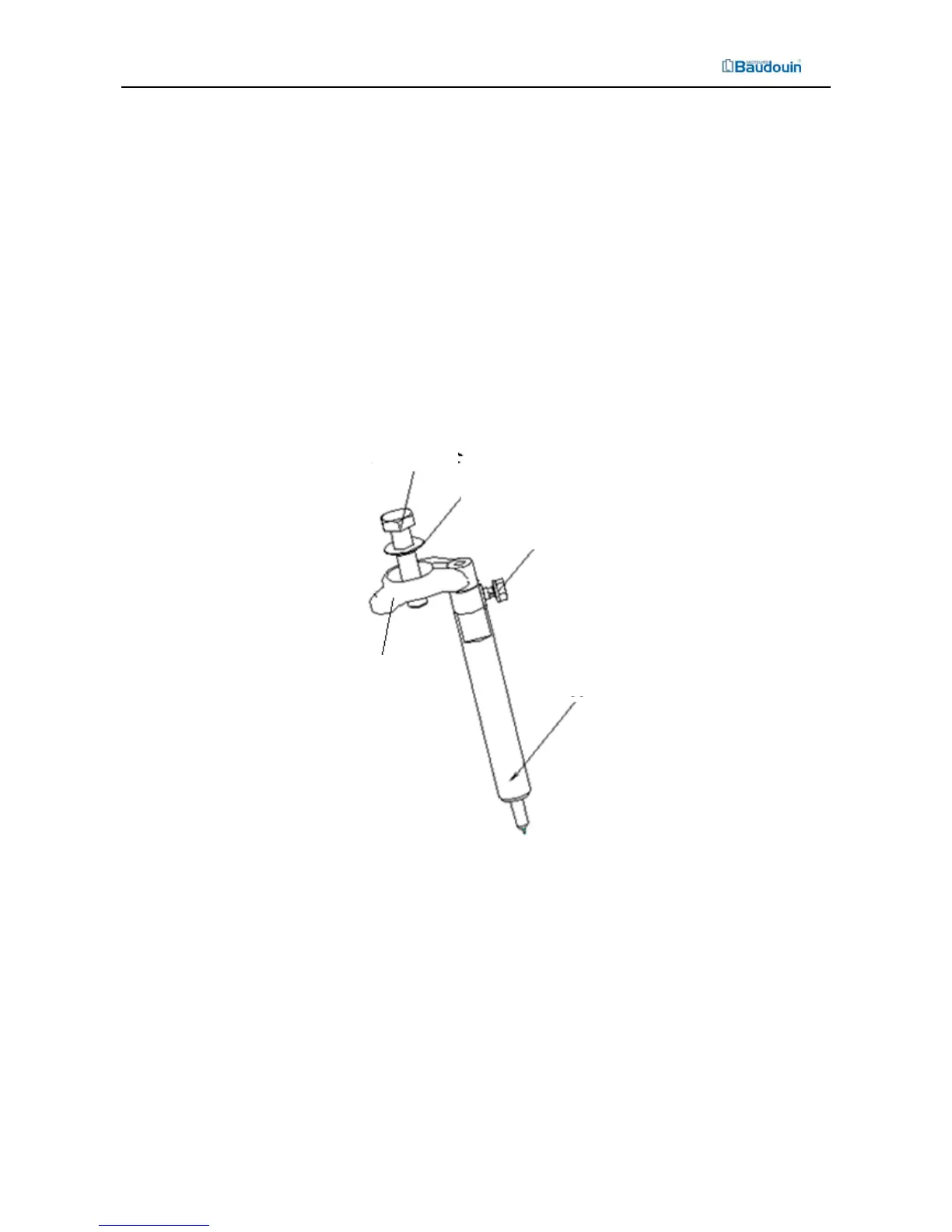

4.7.4.1 Exploded View for Assembly of Fuel Injector

Figure 4-57 Exploded View for Assembly of Fuel Injector

4.7.4.2 Fuel Injector DisassemblyProcedures

①Disassemble the connecting hollow bolts between fuel injectors of various cylinders and fuel

injector fuel return pipe.

②Disassemble the compression bolts of fuel injectors and take out the fuel injector pressure plate.

③Disassemble the fuel injectors by special tool.

4.7.4.3 Inspection and Maintenance of Fuel Injector

①Check the copper seal washer. Upon detection of excessive deformation or other damage, replace

it and at the same time clean the surfaces of fuel injector seat holes to disassemble carbon

Gland bolt

Spherical

washer

Hollow bolt

Fuel injector

Fuel injector pressure

Loading...

Loading...