Advisethecustomerofthenecessityofinformingtheelectricityproviderwithregardtobillingandpayback.SeetheUsersOperatinginstructionssection13.3.

NOTE:Seealsowww.baxi.co.uk/products/getfitwithbaxiecogen

page57

13.0Servicing

13.1General

1.Forreasonsofsafetyandeconomy,itisrecommendedthattheapplianceisservicedannually.Servicingmustbeperformedbyacompetentpersoninaccordancewith

BS79674:2007.

2.Afterservicing,completetherelevantServiceIntervalRecordsectionoftheBenchmarkCommissioningChecklistattherearofthispublication.

NOTE:ServiceandmaintenanceengineersmusthaveundergoneBaxiEcogenTrainingandbeenapprovedtoservicethisappliance.

3.Beforeelectricallyisolatingtheappliance:removealldemandsforheatandensuretheenginehasdisconnectedfromthegrid.(Power=0kW)Thiswillprotecttheengine

fromthestressesproducedbydisconnectingduringelectricitygeneration.

IMPORTANT:

Duringroutineservicing,andafteranymaintenanceorchange

ofpartofthecombustioncircuit,thefollowingmustbechecked:

Theintegrityofthecompletefluesystemandtheflueseals.

TheintegrityoftheboilercombustioncircuitandrelevantsealsasdescribedinSection14.14.

TheoperationalgasinletpressureasdescribedinSection11.5andthegasrateasdescribedin11.3.8.

Thecombustionperformanceasdescribedin'ChecktheCombustionPerformance'(15.1).

4.CompetencetocarryoutCheckingCombustionPerformance

B.S.6798'SpecificationforInstallation&MaintenanceofGasFiredBoilersnotexceeding70kW'advisesthat:

Thepersoncarryingoutacombustionmeasurementshouldhavebeenassessedascompetentintheuseofafluegasanalyserandtheinterpretationoftheresults.

ThefluegasanalyserusedshouldbeonemeetingtherequirementsofBS7927orBSEN503793andbecalibratedinaccordancewiththeanalysermanufacturers'

requirements.

CompetencecanbedemonstratedbysatisfactorycompletionoftheCPA1ACSassessment,whichcoverstheuseofelectronicportablecombustiongasanalysersin

accordancewithBS7967,Parts1to4.

NOTE:Itisnotpossibletoundertakeanyservicingoftheengineanditsburnerandassuchitshouldberegardedasasealedunit.

Whenperformingcombustioncheckseachburnermustberunindependently,seesection15.0CombustionChecks.

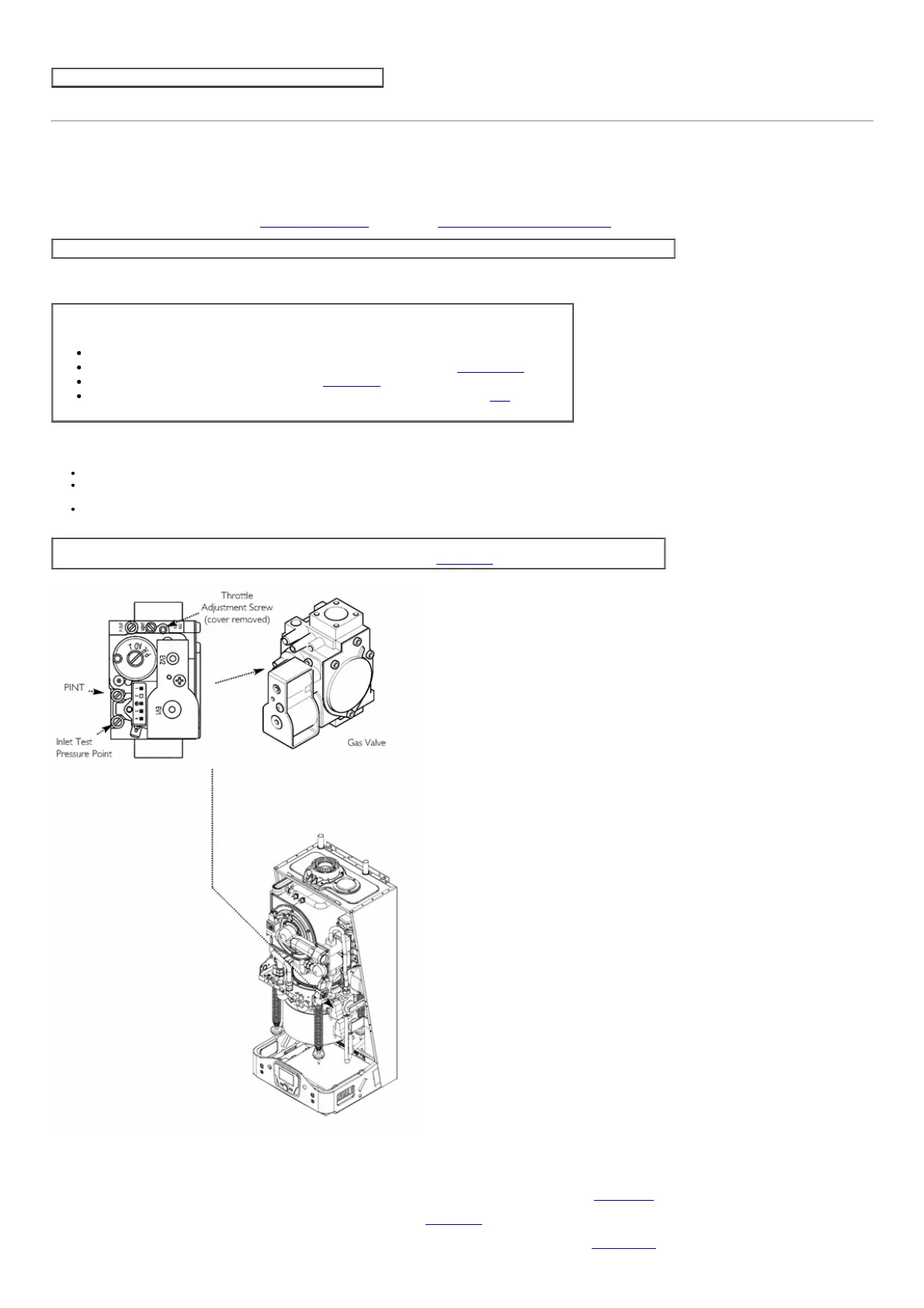

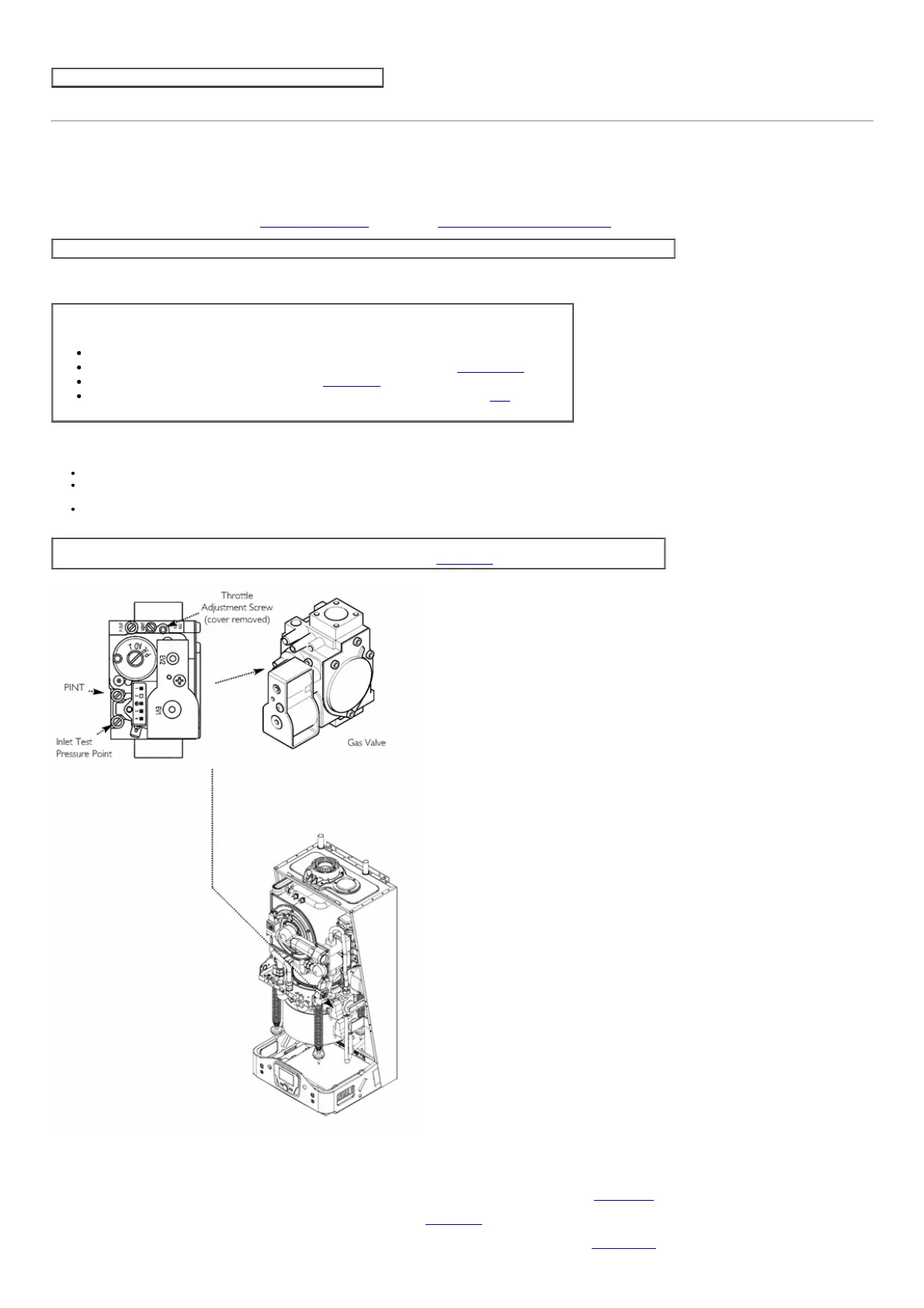

Fig.50

13.2Powergeneration

1.EnsurethesystemiscoldandusethechimneysweepmodetoforcetheEngineburnertomaximumrateseesection15.1.

2.UsetheTHINKControllertoobservethepowergenerated.

3.MonitortheheadtemperatureandthepowerviatheIthinkcontrollerseesection13.3safetynote.

4.Thepowershouldbebetween800to1000Wwithin10minutesoftheengineburnerstartingtheheadtemperatureshouldbebetween450500degC.

5.IfthepowerlevelislowwhentheheadhasreachedtemperaturetheengineisnotproducingpowercorrectlyseesectionQforfaultfindingontheengine.

Loading...

Loading...