page58

13.3ServicingInternalIntegrity

SafetyNote:Beforeremovingthefrontcover;thecorrectshutdownsequencemustbefollowedforyourownsafety.

Beforeservicing,ensurethattheboileriscoolwiththeengineheadbelow120°Cotherwisethereisariskof

electricshockevenwiththesuppliesdisconnected.

TheheadtemperaturemaybeaccessedviatheTHINKController.

PresstheMENUButton.TurntheSelectorButtontohighlight'Information'.

PresstheButtontoselect.TurnSelectorButtonuntil'headtempactualvalue'isshown.

Ensurethatboththegasandelectricalsuppliestotheapplianceareisolatedwaitaminimumof6minutes30seconds

beforeanyworkisstartedagainthereisariskofelectricshockevenwiththesuppliesdisconnected.

NOTE:Beforeundertakinganyserviceworkthatentailstheremovalandreplacementofparts,ensurethatthecenter

transitbracketisrefittedtoprotecttheenginehead(seeFig.48).

Thisbracketmustthenberemovedbeforerunningtheengine.

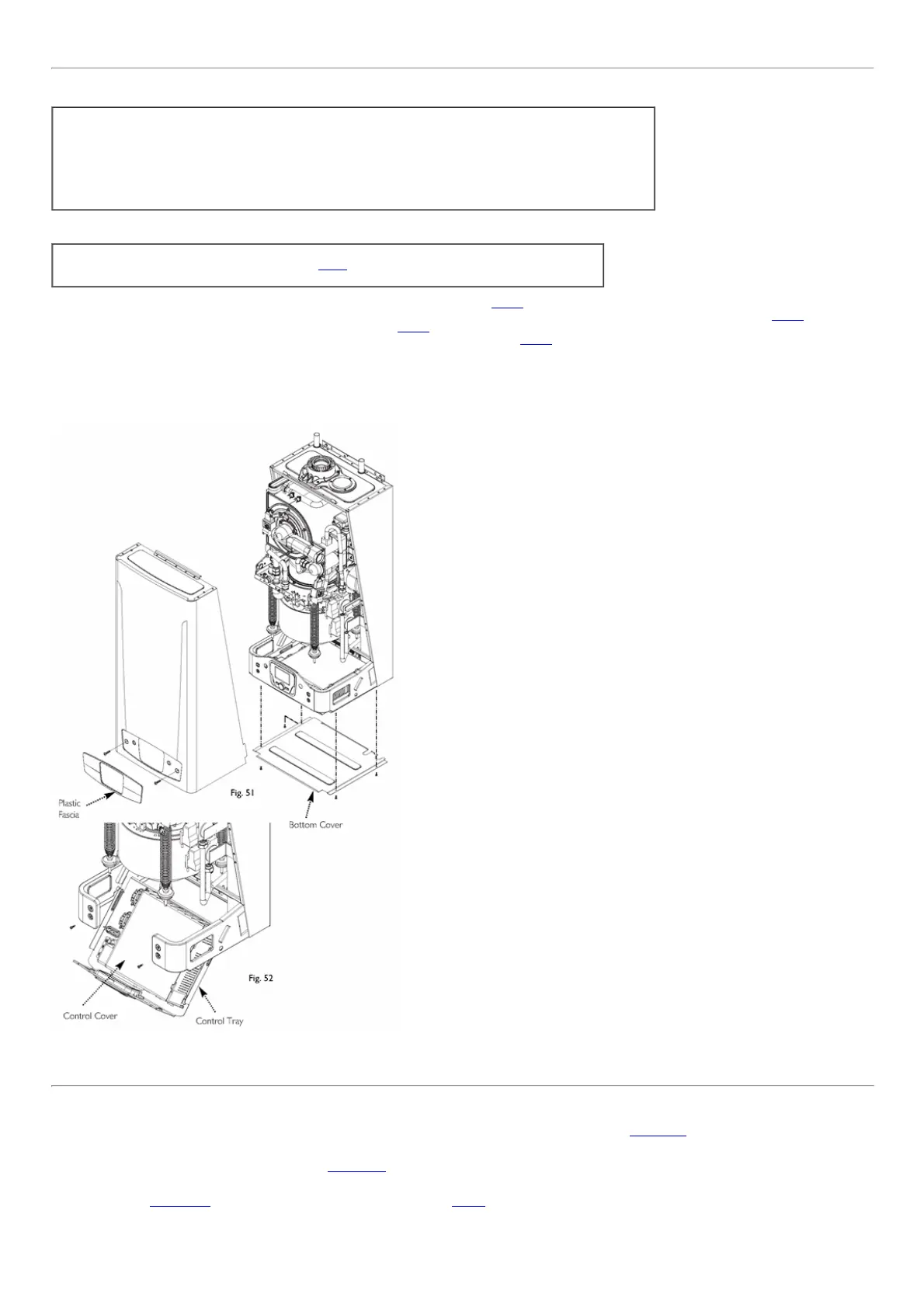

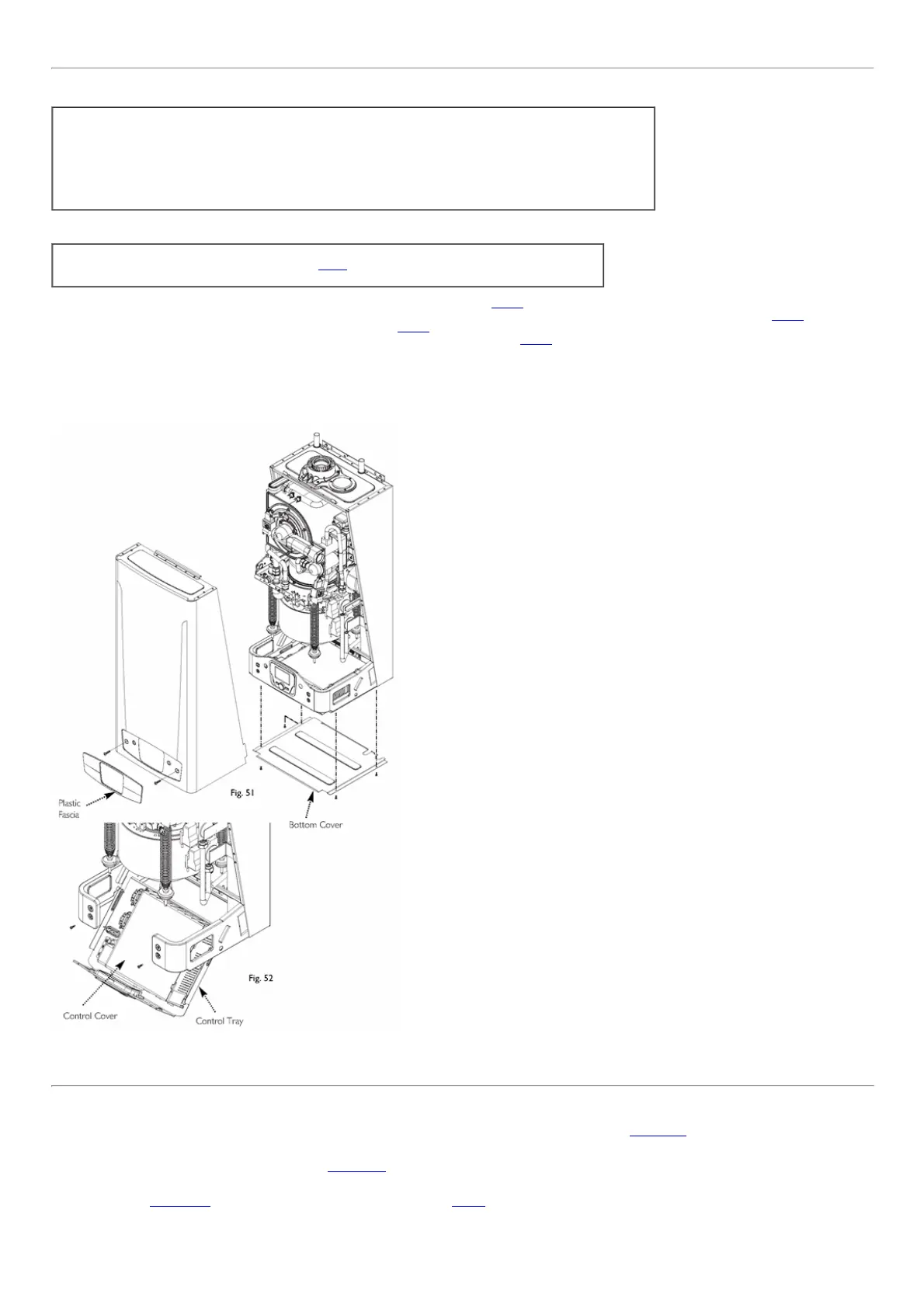

1.Removetheplasticfaciaonthefrontoftheappliancewhichisheldonbytwomagnets(Fig.51).

2.Removethetwoscrewsandthefrontcasebypullingforwardatthebottomedgeandthenliftingclearoftheengagementatthetopoftheappliance(Fig.51).

3.Undothefourscrewsfromthebottomcoverandremovethecover(Fig.51).

4.Removethetwoscrewsonthefrontofthecontroltraytogainaccesstothecontroltrayarea(Fig.52).

5.Inspecttheunitforanysignsofwaterdamageandrectifyanyleaks.

6.Generallychecktheconditionsofthewiringoftheapplianceandtheexternalwiringforandloose/poorconnectionsandremakeifnecessary.

7.Inspecttheconditionofthecondensetrapforsignsofdebrisandpossibleblockage.Ifnecessaryremovetheserviceplug,drainandcleanthecompartment.Replacethe

plug,reassemblethecaseandcheckforcorrectoperationwhentheapplianceisrunning.

8.Checkandcleanthemagneticfilterifitisoftheserviceabletype,otherwisereplacethecartridge.Ifitobservedthatthereisexcessiveamountsofcorrosionproduct

blackresidue/sludgechecktheinhibitorlevelinthesystemandtopupwithinhibitorsolutionasrequired.

Fig.51&Fig.52

page59

13.4ServicingCombustionandRateChecks

1.Performcombustionandratechecksbyusingthechimneysweepmodetoforceeachburnerintomaximumrate(seesection15.0CombustionChecks).Combustion

readingofCO2~8.79.3andCOlessthan100ppmareacceptableforbothburners.MeasuretheCO/CO2ratio.Thisvalvemustbelessthan0.004.

2.Seteachburnerseparatelytoaminimumandcheckthattheburnerstayslitwithcleancombustion.

3.IfthereisaproblemwiththerateorcombustionseeSection15.2.

4.Ifthereisaproblemwiththeignition,thefollowingservicingshouldbecarriedout.

SeeSAFETYNOTESection13.3EngineIgnitionandFlameSensingElectrodes(Fig.53)

1.Detachtheignitionandflamesenseleadsfromthewiringharnessnotingtheirpositions.

2.Undothelongnuts(7mmspanner)retainingtheengineignitionandflamesenseelectrodes.

3.Carefullywithdrawtheelectrodesfromtheengine.

Loading...

Loading...