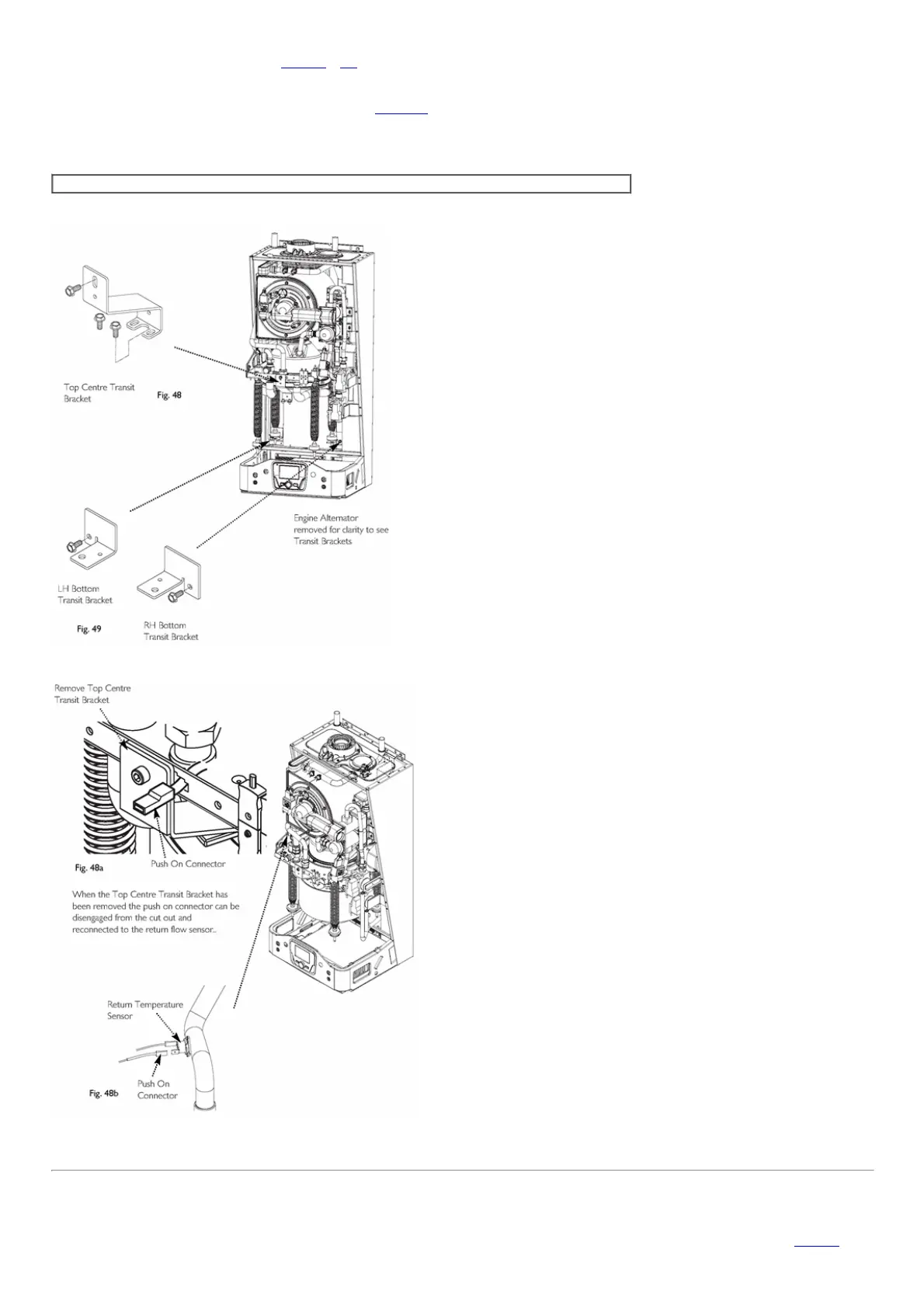

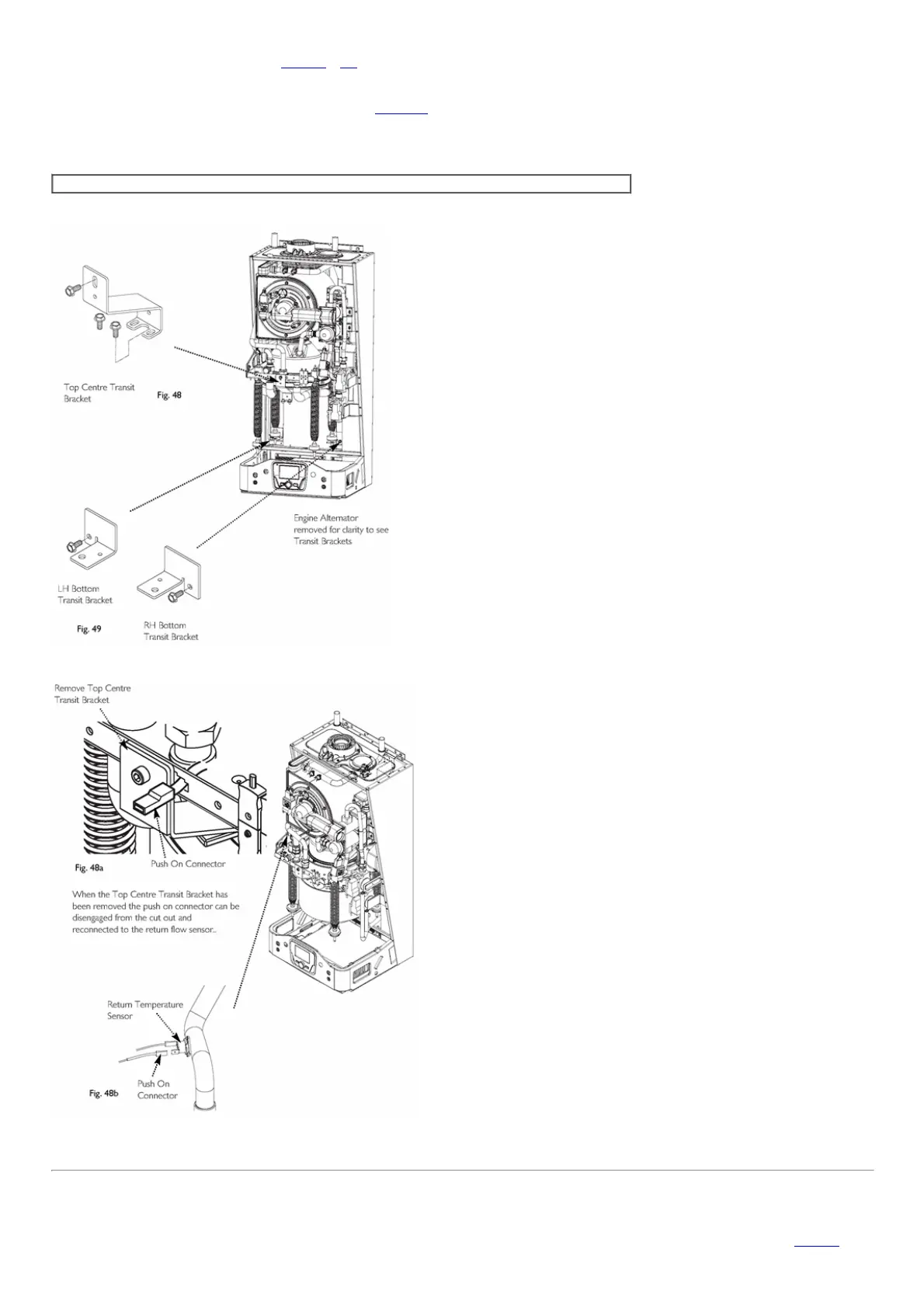

b)Thiswillreleasethesecondsecuritymeasurenowthatthetopbrackethasbeenremoved.Thepushonconnectorcanbedisengagedfromthecutoutand

reconnectedtothereturntemperaturesensor(Figs.48a&48b)(theappliancewillnotoperateuntilthisreconnectionismade,Error40willshow).

2.Refitthecontroltray,thebottompanelandtheoutercasebeforeswitchingontheappliance.

3.Ensurethatthefillingloopisconnectedandopen,thenopentheheatingflowandreturnvalvesontheboiler.

4.ThesystemmustbeflushedinaccordancewithBS7593(seeSection6.1)andtheflushingagentmanufacturersinstructions.

5.Pressurisethesystemto1.5barthencloseanddisconnectthefillingloop.

6.Turnthegassupplyonandpurgethesystemaccordingtoin

GBBS6891(NaturalGas)BS54821(PropaneGas)andin

IEI.S.813"DomesticGasInstallations".

IMPORTANT:LockoutmayoccurandErrorCodesE261&E262displayedifthegassupplypipeisnotadequatelypurged.

7.Testforgastightness.

Fig.48&Fig.49

Fig.48a&Fig.48b

page51

11.3CommissioningofControls

Everytimetheapplianceispoweredup,thecontrolscarriesout2checkingfunctions

a)315:InitializationMainPCBgathersdataonconnectionsandsensors.Thistakesaround2minutes.

b)312:DeaerationFunctionallcirculationvalvesareopenedandthecirculatingpumpisexercised.Onfor6secondsofffor5secondsfor4.5minutes.Seesectiong)De

aerationfunction

Loading...

Loading...