BA series pumps

Pump unit with diesel drive 1401

8.24

Work on the electrical system

WARNING

Batteries generate explosive gases. Keep them away from naked flame and sparks

which could cause them to ignite. Do not smoke.

Protect the eyes, skin and clothing against battery acid. Pour clear water over acid

splashes immediately. In case of emergency call doctor.

Do not place any tools on top of the battery.

Always disconnect the negative (–) pole of the battery before working on the electric

device.

–The positive (+) and negative (-) battery terminals must not be accidentally interchanged.

– When installing the battery, connect the positive (+) lead first, followed by the negative (-) lead.

Negative pole to earth (ground) on engine block.

– When removing the battery, disconnect the negative (-) lead first, followed by the positive (+)

lead.

– In all circumstances, avoid short circuits and shorts to earth (ground) at live cables.

– If electrical faults occur, first check for good contact at the cable connections.

– Replace a failed indicator light without delay.

– Do not take the key out while the engine is running.

– Never disconnect the battery while the engine is running. Electric voltage peaks can cause

damage to electrical components.

– In case of an emergency start in manual mode, leave the battery (which might be discharged)

connected to the engine.

–For emergency operation without battery, make sure that the plug-and-socket connector to the

instrument box is also disconnected before the engine is started.

– Do not splash electrical devices with water jet or pressure jet during engine cleaning.

– When carrying out welding work on the engine or attached equipment, attach the earth (ground) clip

as near as possible to the welding point,

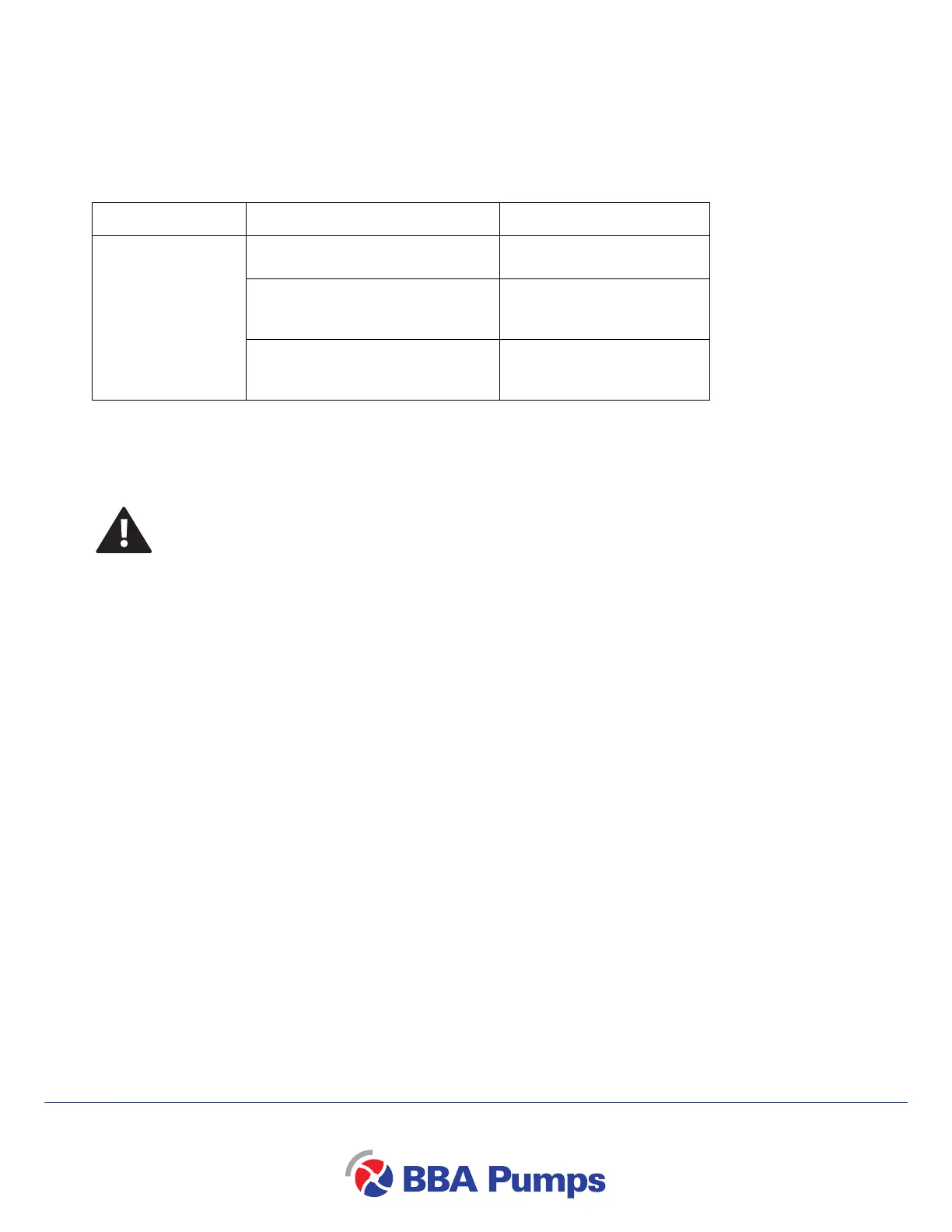

Malfunction Possible causes Remedial action

Engine runs very hot.

Cylinder head

overheat, telltale

lamp (optional extra)

comes on.

Too much oil in engine. Drain off engine oil down to

upper mark on dipstick.

Inadequate cooling:

- Entire cooling air system

contaminated.

Clean cooling air system.

- Inadequate sealing at air guide

plates or capsule elements.

Check that air guide plates and

enclosure elements are all

present and make a tight seal.

Loading...

Loading...