23

1. TheTABS-6AdvMCmoduleshallbeinstalledwiththe

followingconsiderations(seeFigures16through18):

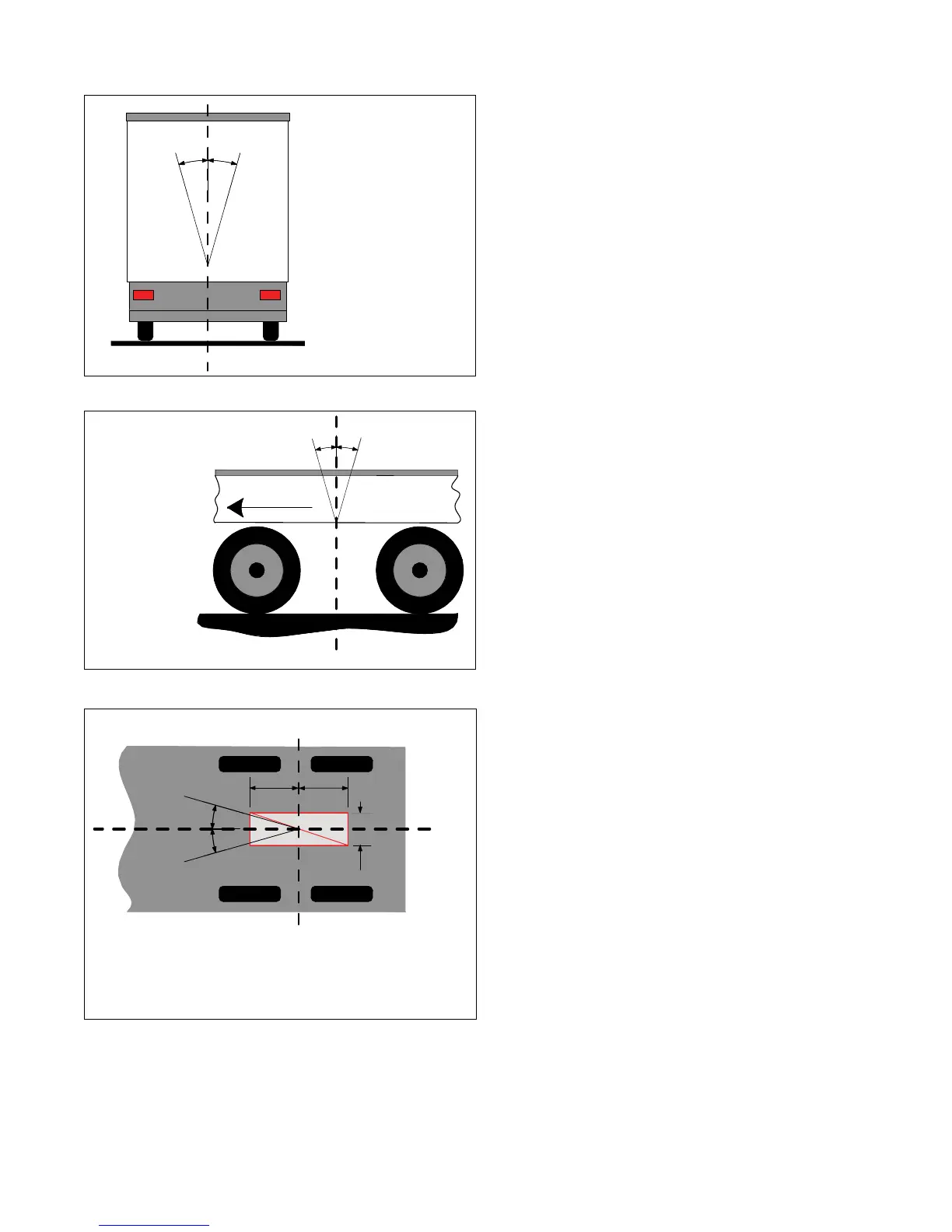

5°

5°

VERTICAL

ORIENTATION

(ROLL ANGLE)

MUST BE

WITHIN FIVE

DEGREES OF

VERTICAL

FIGURE 16 ‑ INSTALLATION ON TRAILER (VERTICAL)

10°

10°

Driving

Direction

Longitudinal

Orientation

(Pitch Angle)

Must be within

Ten Degrees of

Vertical

FIGURE 17 ‑ INSTALLATION ON TRAILER (LONGITUDINAL)

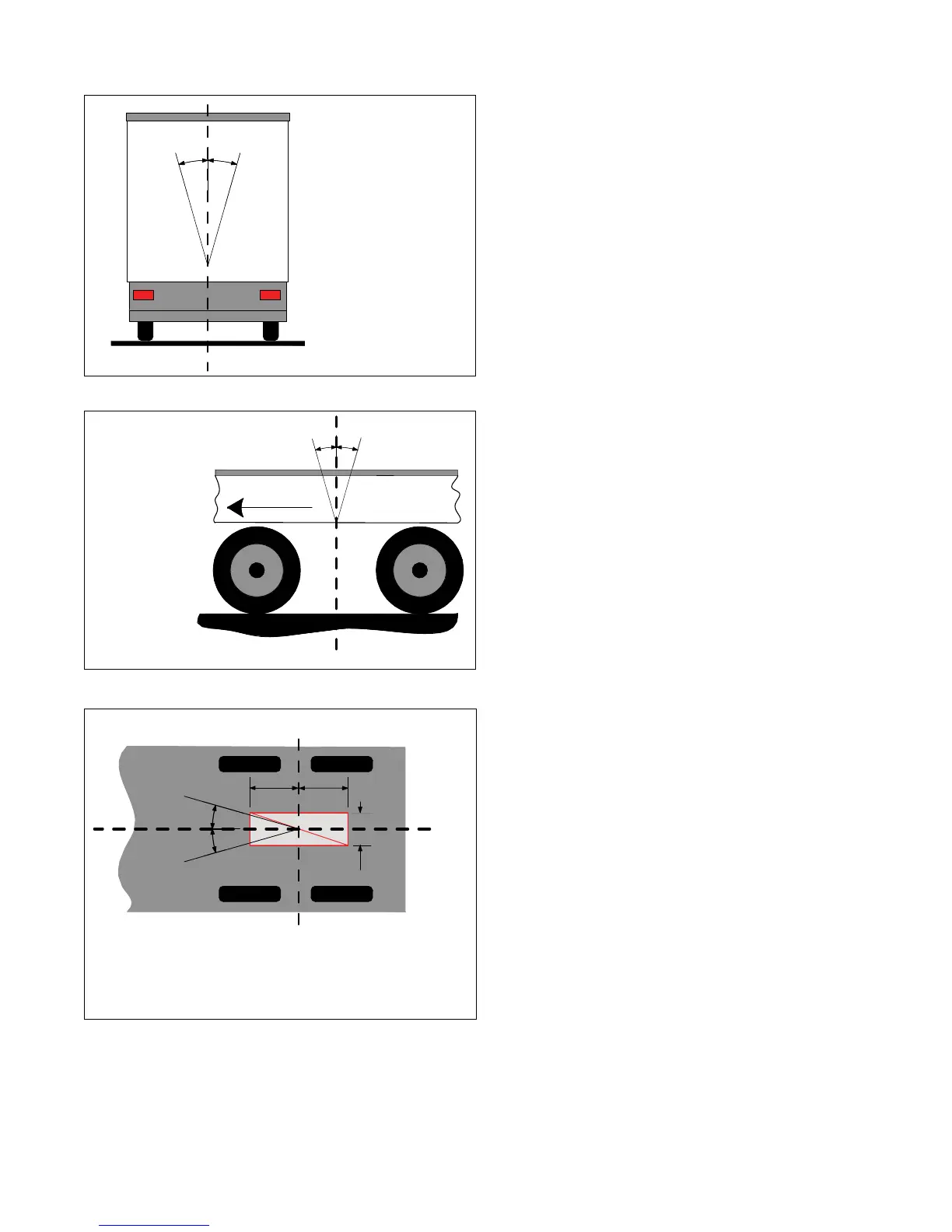

The TABS-6 Adv MC module must be located no

more than 40 inches from the mid-point between

the axles, and within two inches from the center

line of the trailer (unless congured for an offset).

10°

10°

± 40" (1 m) from mid-point between the axles

± 2" (5 cm)

from center

of trailer

FIGURE 18 ‑ INSTALLATION ON TRAILER (CENTER LINE)

• With exhaust port facing downward and unobstructed

withsignicantfreespacebelow(>1inch).

• Within±40"ofthecenteroftheaxle(s)forproper

balanced brake applications.

• Within±2"fromthecenterlineofthetrailer(default).

Note,aleft/rightoffsetgreaterthan±2"mayhave

beenprogrammedintheECUandcanbeveried

using Bendix ACom diagnostic software (version

6.1orhigher).

• Yaw angleshall be ± 10°as measured from the

center line of the trailer.

• Pitchangleshallbe±10°asmeasuredfromaat

horizontal plane.

• Roll angle shall be within ± 5° as measured from a

athorizontalplane.

Frame‑mount module: The TABS‑6 Adv MC module

usesthreeClass8steelM10x1.5nutswithlockwashers,

torquedto354±44.4in.-lbs(40±5Nm).

2. Reconnect all air hoses and plugs to the module.

Depending on the installation, additional plugs may

be necessary. Thread sealant products that contain

Teonmaybeused,howeverthreadsealanttapeisnot

recommended as there is a potential for tape material

entering the valve and affecting the valve’s operation.

Make certain that no thread sealant enters the valve.

Allairhosesandttingsshouldbecheckedforleaks

prior to returning the vehicle to service.

3. Reconnect the ECU power, auxiliary if present and

wheelspeedsensorelectricalconnectorstotheECU.

Apply a moderate amount of non‑conductive electrical

grease to each connector pin before reconnecting.

Note:Thewheelspeedsensorsmustfollowtheorienta‑

tionofthemoduleasshowninFigure19forxedaxle

trailers. Where a lift axle is present, and sensors are

tobeinstalledonthataxle,secondarysensorsSEand

SF must be used for the lift axle.

• Itisnecessarytoxthewheelspeedsensorsto

the orientation of the lateral acceleration sensor for

plausibility checks between the sensors.

• If the wheel sensor location does not match the

orientation of the Bendix

®

TABS‑6

™

Adv MC module

shown in Figure 19, a Diagnostic Trouble Code

(DTC)willbegeneratedandtheABSindicatorlamp

will be illuminated.

• Refer to the raised lettering on the top cover for

wheelspeeddesignation,“S-C”,“S-D”,“S-E”,and

“S‑F”.

4. Leakage and OperationalTests must be performed

before returning the vehicle to service.

LEAKAGE AND OPERATIONAL TESTS

1. Beforeperformingtheleakagetests,blockthewheels.

2. Fully charge the air brake system and verify proper

brake adjustment.

3. Makeseveraltrailerbrakeapplicationsandcheckfor

prompt application and release at each wheel.

Loading...

Loading...