24

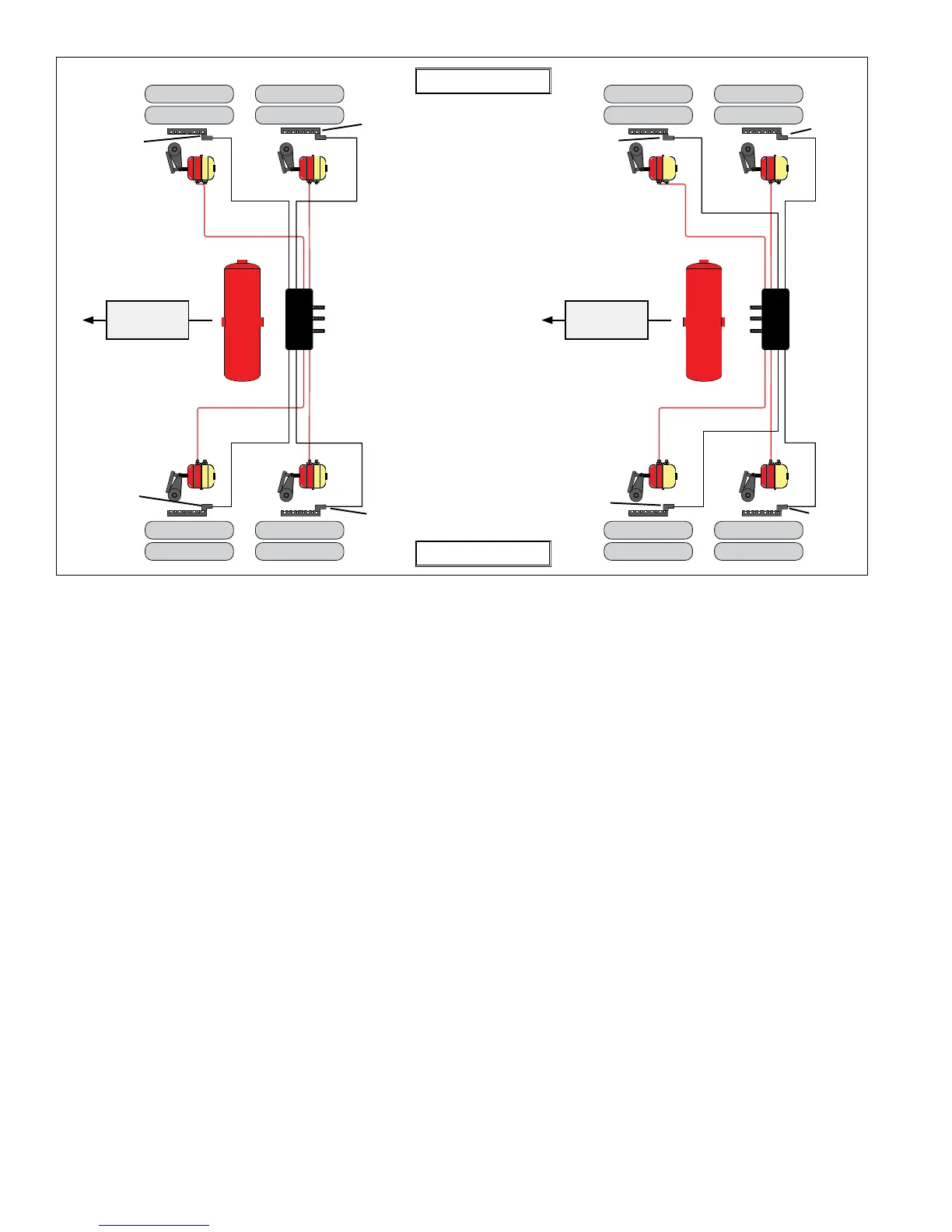

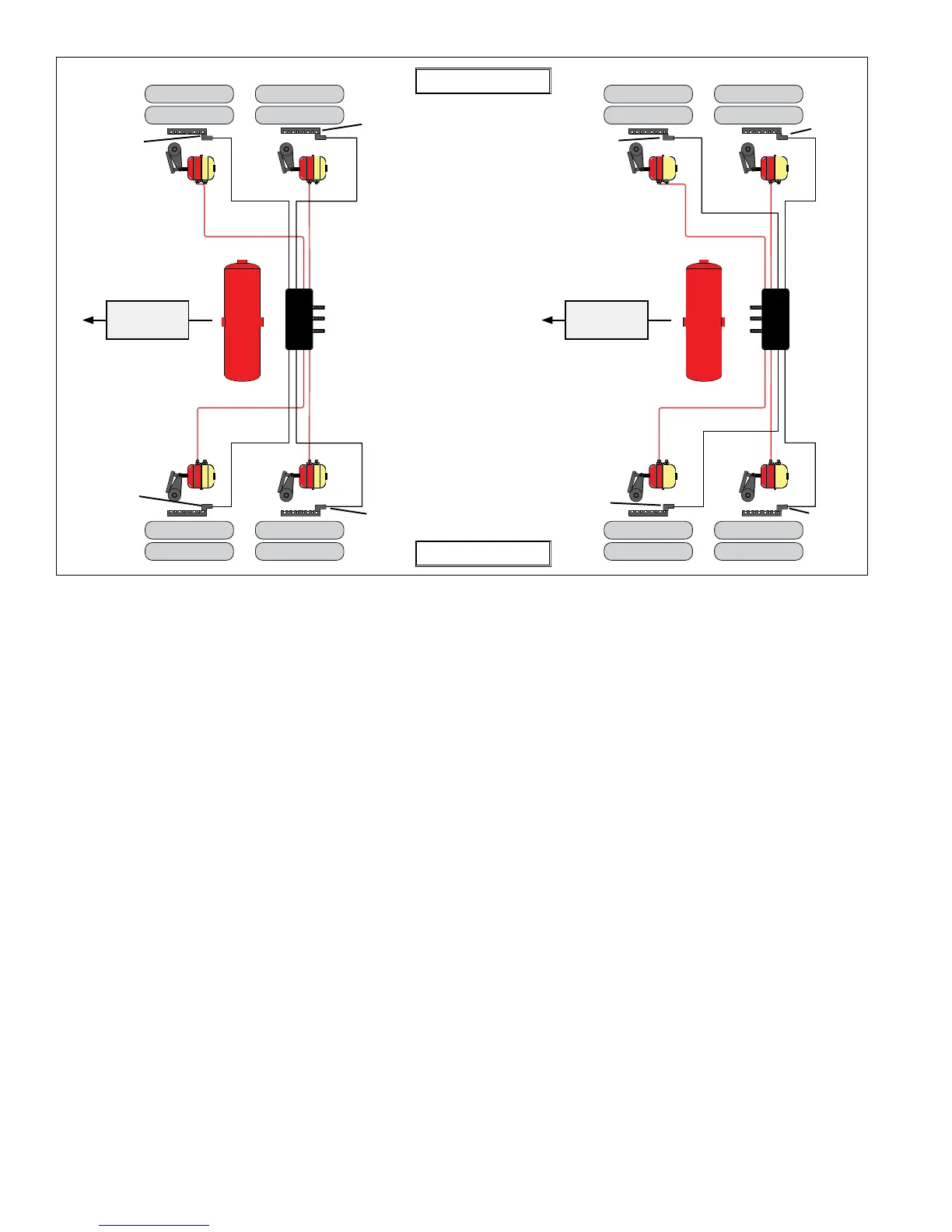

FIGURE 19 ‑ WHEEL SPEED SENSOR INSTALLATION

P22

P21

P21

P22

0° Mounting Orientation 180° Mounting Orientation

Vehicle Driving

Direction

Vehicle Driving

Direction

Right - “Curb Side”

Left - “Road Side”

Sensor

“S-F”

Sensor

“S-D”

Sensor

“S-C”

Sensor

“S-E”

Sensor

“S-E”

Sensor

“S-D”

Sensor

“S-F”

Sensor

“S-C”

4. Check the TABS‑6 Adv MC module, modulator valve(s)

and all air hose fittings for leakage using a soap

solution.

Check the ABS solenoid body with the trailer service

brakes fully applied. If leakage is excessive — more

thanasingle1"bubblewithin1minute—replacethe

TABS‑6 Adv MC module.

Check the relay exhaust port with the trailer service

brakes released to be sure that leakage is less than

a single 1" bubble within 3 seconds. If excessive

leakage is detected at the relay exhaust port, perform

the following test before replacing the TABS‑6 Adv MC

module:

• Apply the trailer spring brakes. Recheck for leakage

around the relay exhaust port. If the exhaust port

stops leaking, this indicates a leak between the

emergency and service sides of the spring brake

chamber. However, if the relay exhaust port

continues to leak excessively, replace the TABS‑6

Adv MC module.

5. Applypowerand monitorthe power-upsequence to

verify proper system operation. See Section 15.

6. Calibrate and set odometer parameters, if necessary,

using a diagnostic tool. See Section 16.

7. Perform an installation test using a diagnostic tool.

Minimum teststhat are required to verify the proper

installation of the ABS/TRSP system are:

• ECU Information: This test provides the user with

specic ECU information. It is required that no

DTC’s(otherthan“end-of-linetestnotcompleted”)

arepresentandthattheECUhasbeencongured.

• Wheel End Sequence Test: During thistest,

checks are carried out that verify the correlation of

the wheel installed with a Wheel Speed Sensor and

the Pressure Modulator that controls the pressure

to the associated brake.

• Lateral Acceleration Test: The installation angle

informationisretrievedfromtheECUandcompared

tothepredenedlimits(+/-5 degrees).Thistest

veriesthattheunitisinstalledasclosetohorizontal

as possible.

• Pressure Sensor Test: Duringthistest,checksare

carried out that verify that the proper response is

received from the pressure sensors during a brake

application.

• Axle Load Sensing Test (Air Ride): The test

has the user verify the expected measurement

of the load pressure sensor, Port 42, for air ride

suspensions. The program provides the reading

of the sensor.

Loading...

Loading...