12

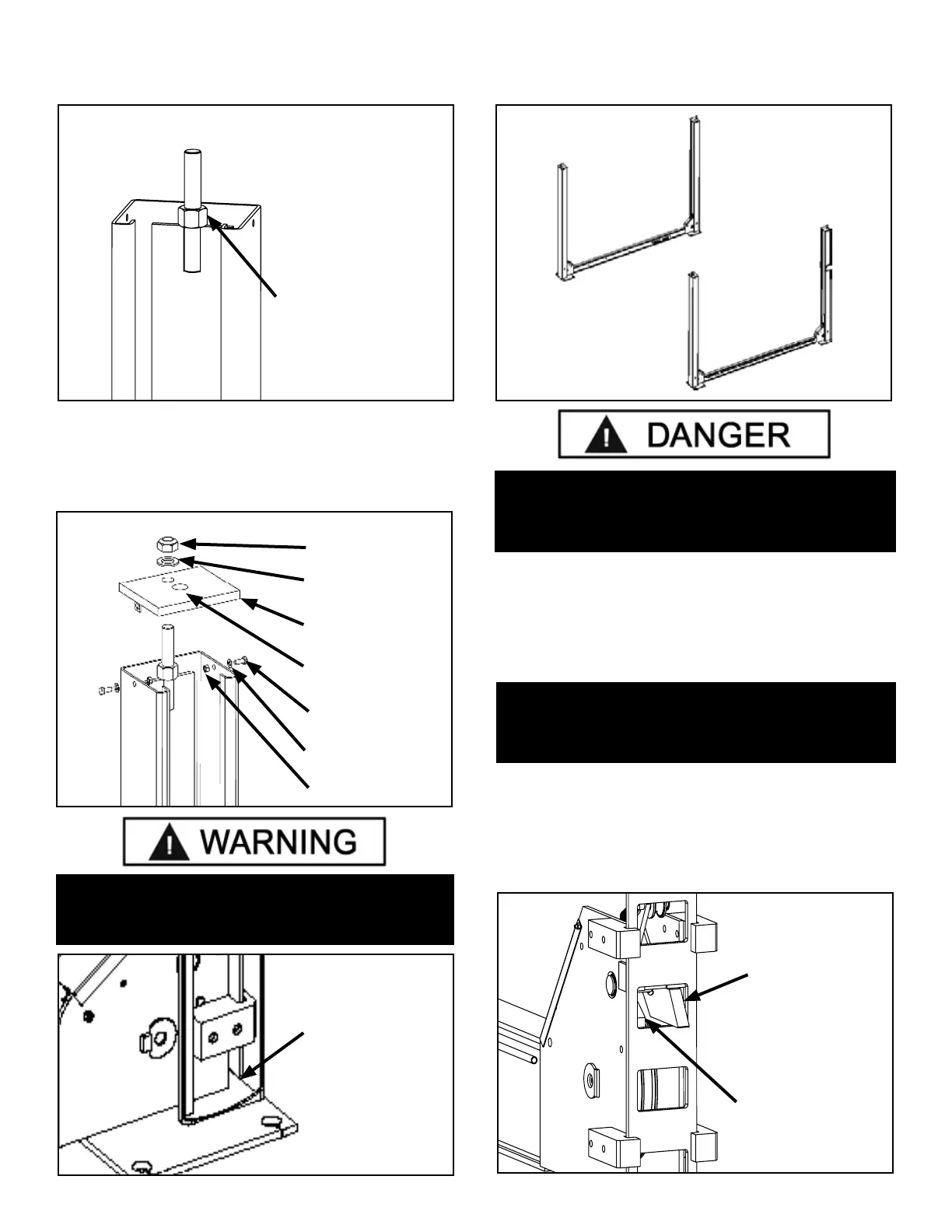

5. Install an M16 jam nut on to ladder bolt prior to the

installation of the Top Plate weldment. (See Fig 3.5)

6. Install the post TOP PLATES using the M6 hex bolts,

nuts & washers. Install the nut on each safety ladder un-

til at least 1/2” of threads are exposed and the ladder is

raised at least 1/2” off of the base plate. Be sure to posi-

tion the cable hole INWARD. (See Fig. 3.6 - 3.7)

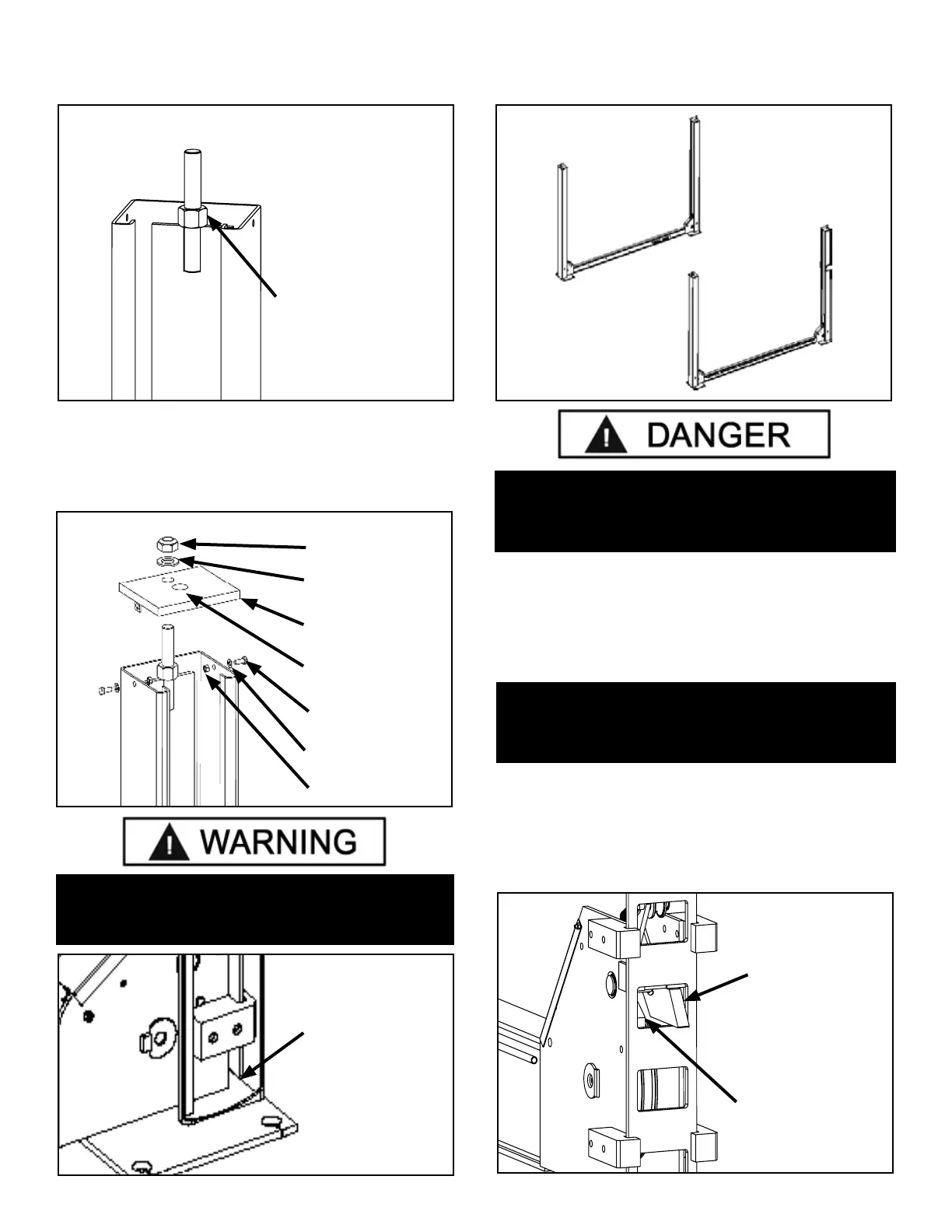

7. The posts and crosstubes are now in position for

ramp installation. (See Fig 3.8)

STEP 4

(Raising The Crosstubes)

1. Crosstubes must be raised off the ground to facilitate

cable routing and ramp assembly.

2. Manually raise the Cross Tubes until the Primary

Safety Locks engage and rest on the third or fourth lock

position or approximately 24” o the ground. It is impor-

tant that the SLACK SAFETY LOCK IS DISENGAGED. The

Slack Safety Locks must NEVER rest on the Safety Lad-

ders. (See Fig. 4.1 - 4.4)

Jam Nut must be

installed prior to the

installation of Top

Plate weldment

Fig 3.5

M6 Nut

M6 Washer

M6 Bolt

Top Plate

Weldment

M16 Washer

M16 Nut

Cable Hole

Fig 3.6

Fig 3.7

The Ladder must

never rest on the

base of the column

or damage to the lift

will occur

WARNING!

RAISE THE SAFETY LADDER AT LEAST

1/2” ABOVE THE BASE PLATE OR DAMAGE

TO THE LIFT WILL OCCUR.

Fig 3.8

DANGER!

BE CAREFUL NOT TO DISTURB THE POSTS AND

CROSSTUBES AS THEY MAY TIP OVER CAUSING

PERSONAL INJURY OR HARM.

IMPORTANT NOTE !

IT IS IMPORTANT THAT THE SLACK SAFETY LOCK IS

CLEARED. THE SLACK SAFETY LOCK MUST NEVER

REST ON THE SAFETY LADDER.

Fig 4.1

Primary Safety

Lock Engaged

Slack Safety Lock

Disengaged

Loading...

Loading...