20

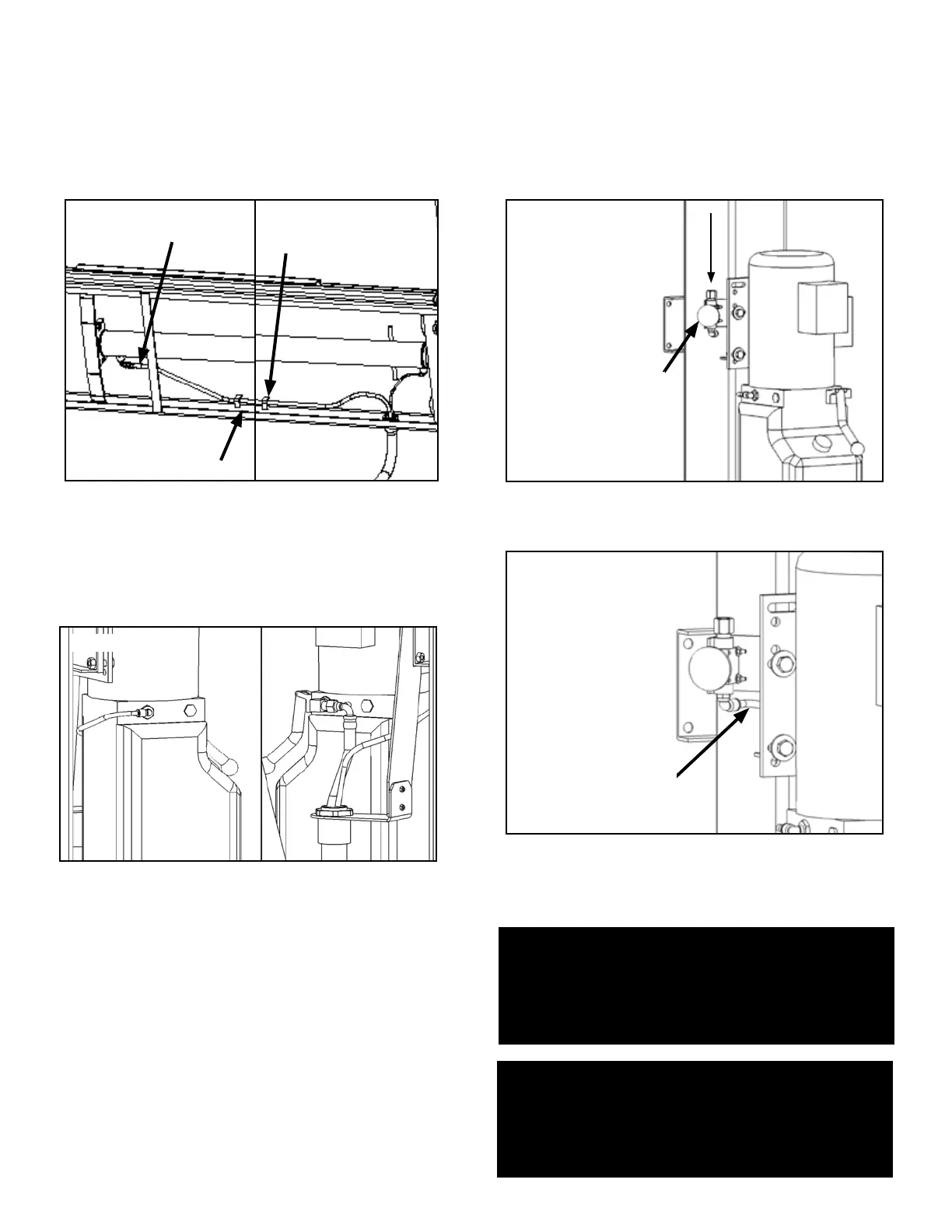

7. Connect the hydraulic hose and air line as shown

below making sure the hydraulic hose passes through the

retaining rings. MAKE SURE HOSES ARE KEPT CLEAR OF

CABLES. There will be one air line hose left unconnected in

this step. This air line will be used to activate the pneumatic

safety locks in the next step. See page 19 for Compression

Fitting instructions. (See Fig. 9.8)

8. Connect the straight end of the Power Unit Hydraulic

Line to the 90° Power Unit Fitting. Connect the Return Air

Line to the 90° Air Fitting. There will be one air line hose

left unconnected at this time. This air line hose will be used

to activate the pneumatic safety locks on the next page.

(See Fig. 9.9)

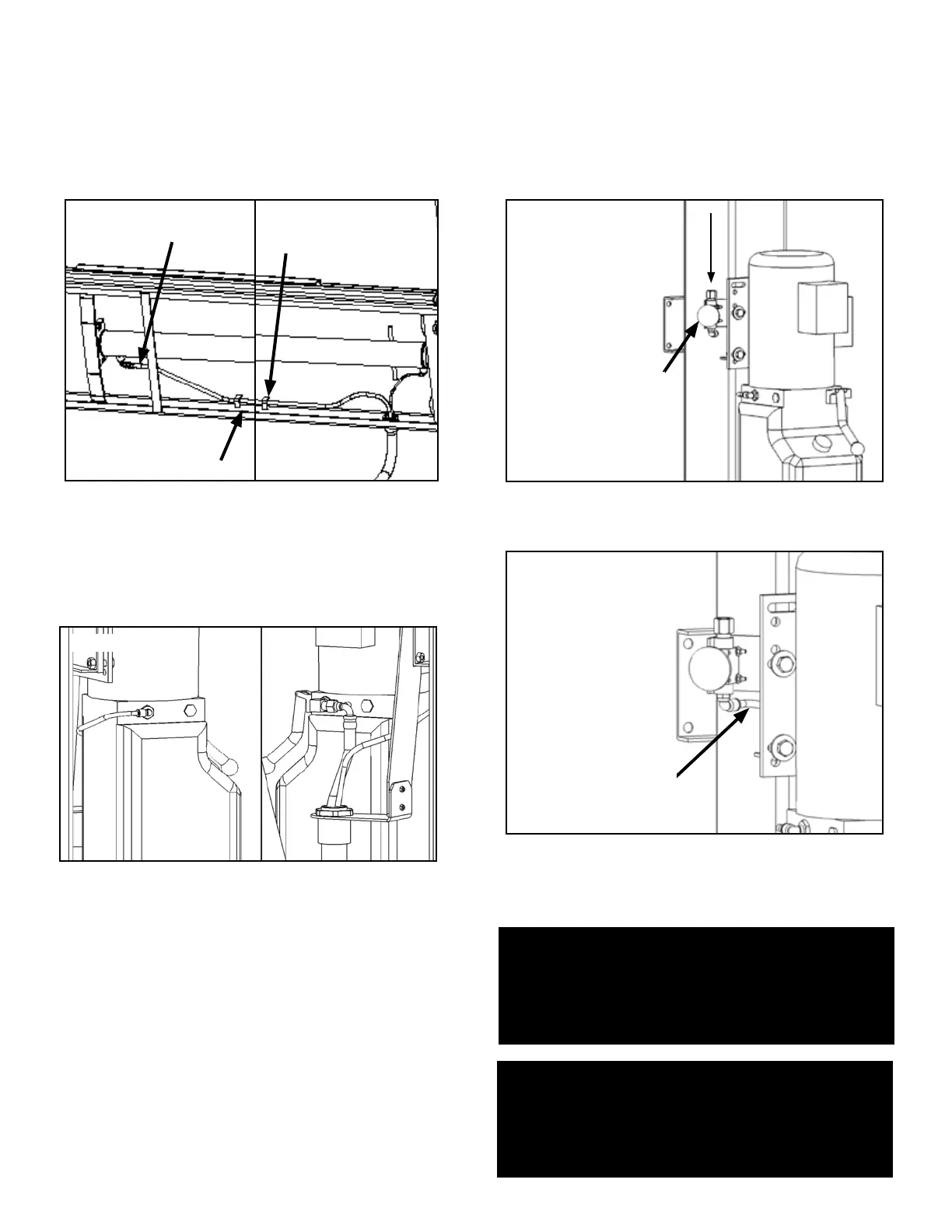

STEP 10

(Routing Air Lines)

1. Mount the Push Button Air Valve Assembly on to the

power unit mounting bracket. The Push Button Air Valve

should be positioned away from the Power Side Ramp on

the “out” side of the lift for operator safety. (See Fig 10.1)

2. Route the air line that was left unconnected in Step 9

to the 90° Air Line Compression Fitting of the Push Button

Air Valve Assembly. (See Fig 10.2)

3. Once the air line has been connected with the Push

Button Air Valve, cut the air lines to length by following

the Safety Air Line Routing diagram located on Page 20

and connect female branch “tee” fittings where needed.

Fig. 9.7

Retaining Ring

Retaining Ring

Straight Hose End

Fig. 9.8

Fig. 10.1

Air Supply In

Fig. 10.2

NOTE:

A FILTER/REGULATOR/LUBRICATOR MUST BE

INSTALLED ON AIR SUPPLY AT LIFT. FAILURE TO DO

SO WILL VOID THE WARRANTY.

NOTE:

MAKE SURE THE PUSH BUTTON AIR VALVE PORT

MARKED “INLET” IS FACING TOWARDS THE SOURCE

OF COMPRESSED AIR.

Push Button

Air Valve

Assembly

To Flex Hose

Loading...

Loading...