25

STEP 13

(Lift Start Up / Final Adjustments)

1. Make sure the Power Unit Reservoir is full with four

(4) gallons of 10-WT hydraulic oil or Dexron-III automatic

transmission fluid.

2. Spray the inside of the posts where the Slide Blocks

glide with a light spray-oil.

3. Test the Power Unit by pressing the push-button

switch on the motor. If the motor sounds like it is operat-

ing properly, raise the lift and check all hose connections

for leaks. If the motor gets hot or sounds peculiar, stop

and check all electrical connections.

4. Before proceeding, make sure all cables are prop-

erly positioned within the grooves of ALL sheaves. Make

sure all Cable Sheave Retaining Clips and or Screws are

secure.

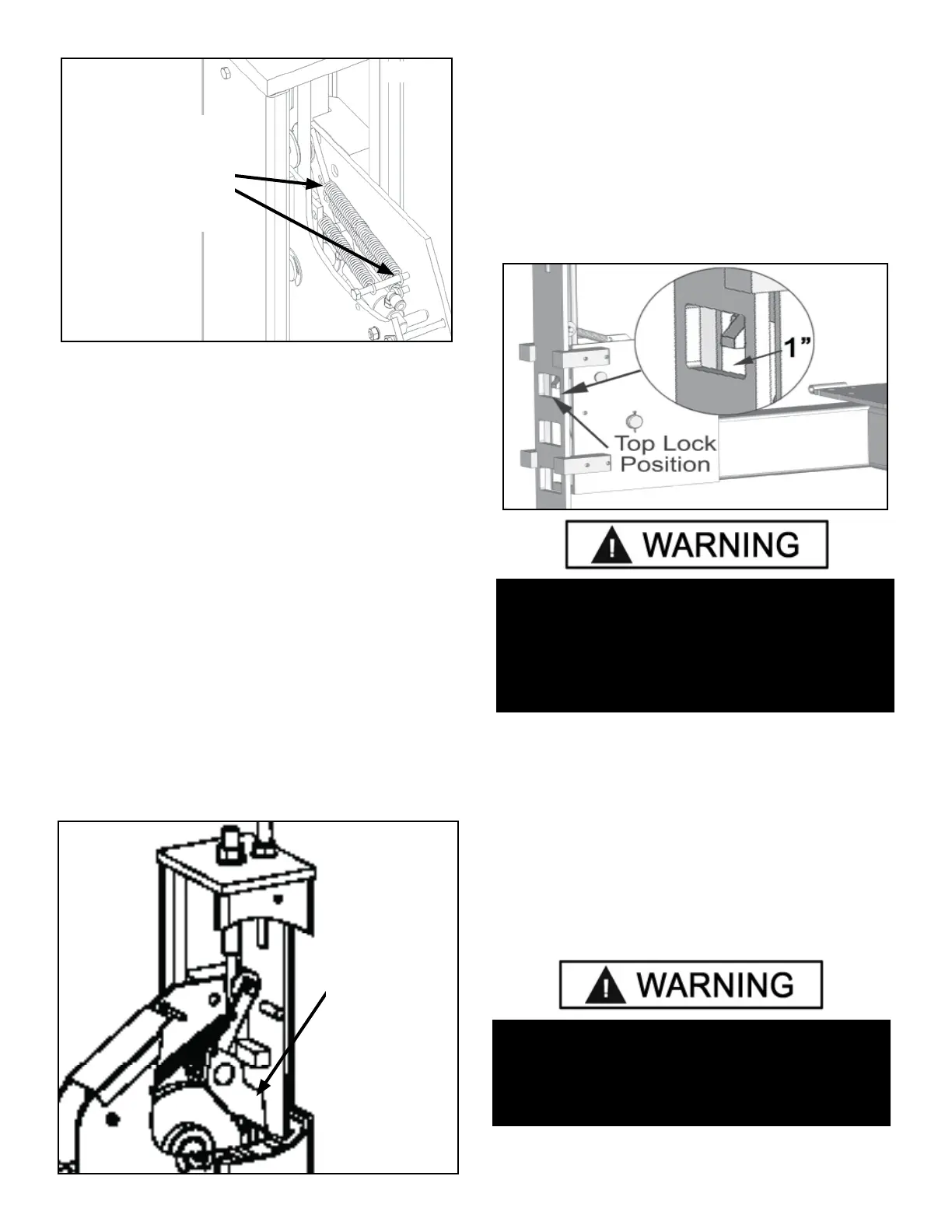

5. Check to make sure that all slack safety locks are

cleared and free. (See Fig. 13.1)

6. Continue pressing the raise button until the cables

are taut and the lift starts to move.

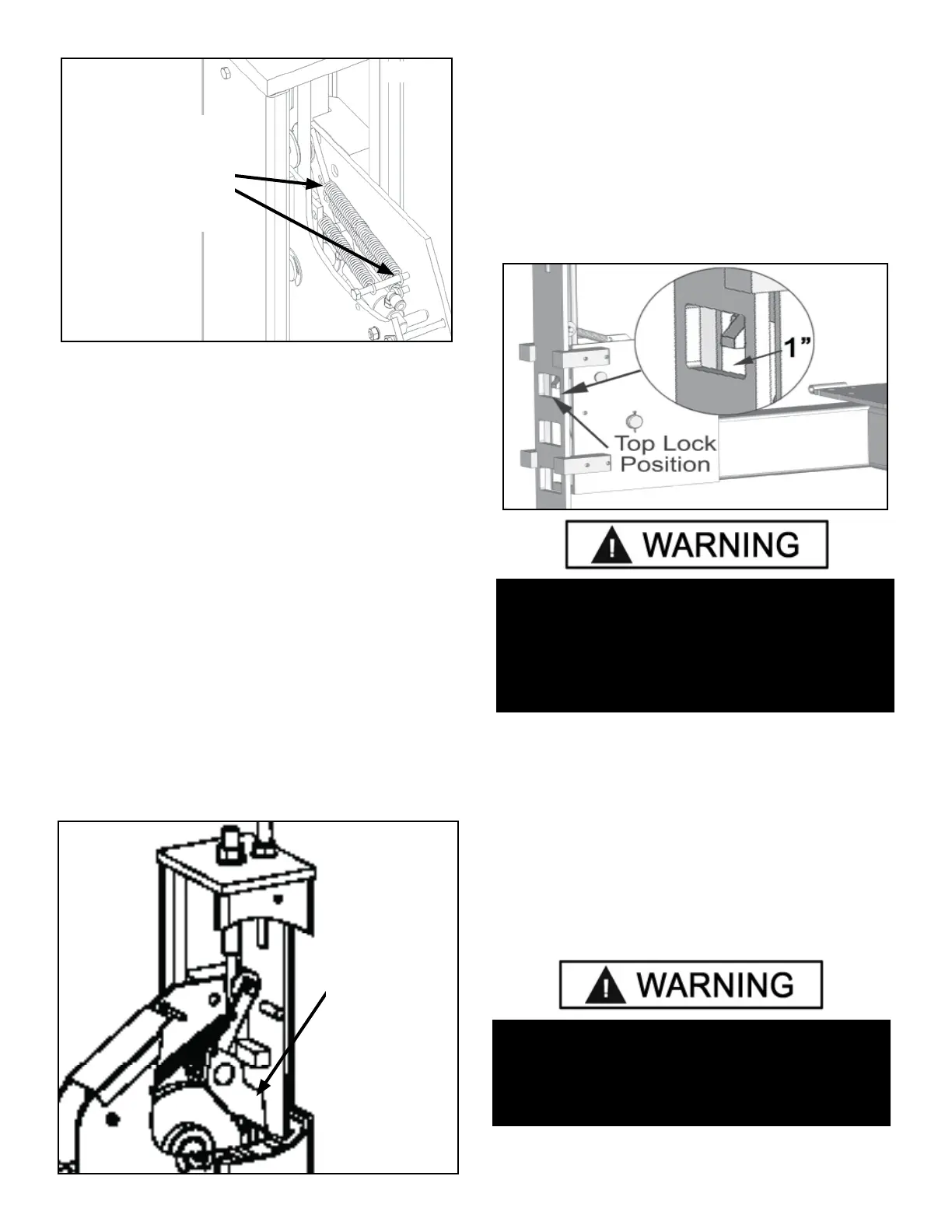

7. RAISE LIFT UNTIL THE CYLINDER BOTTOMS OUT

AND THE LIFT STOPS. ADJUST EACH CABLE SO THAT

EACH SAFETY LOCK RESTS AT ONE INCH ABOVE THE

TOP SAFETY LOCK POSITION. It may be necessary to

tighten or loosen each Cable to reach the proper height.

The Cable Nuts MUST be tightened until there is at least

one inch of threads protruding through the nut. (See Fig.

13.2)

NOTE:

There will be initial stretching of the cables in the

beginning and/or with increased loads. Adjust the

Cables

as outlined above a week after first use, then every

three to six months thereafter depending on usage

and/or to compensate for stretch.

8. After connecting the air supply, press the PUSH

BUTTON AIR VALVE and check that all safety locks are

functioning properly. Lower the lift by pressing the push

button air valve and power unit lowering valve simulta-

neously.

WARNING!

ALL CABLE NUTS MUST BE TIGHTENED ON EACH

END UNTIL THERE IS AT LEAST ONE INCH OF

THREADS PROTRUDING THROUGH THE NUT.

FAILURE TO DO SO COULD RESULT IN SERIOUS

INJURY OR DEATH.

Fig 13.1

Slack safety

should be

positioned as

shown

Fig 12.1

Make sure the ends

of all three (3) springs

are securely attached

to the Safety Locks

and Cross Tube

anchor points.

Fig 13.2

WARNING!

KEEP HANDS AND FEET CLEAR. REMOVE HANDS

AND FEET FROM ANY MOVING PARTS. KEEP FEET

CLEAR OF LIFT WHEN LOWERING. AVOID PINCH

POINTS.

Loading...

Loading...