12

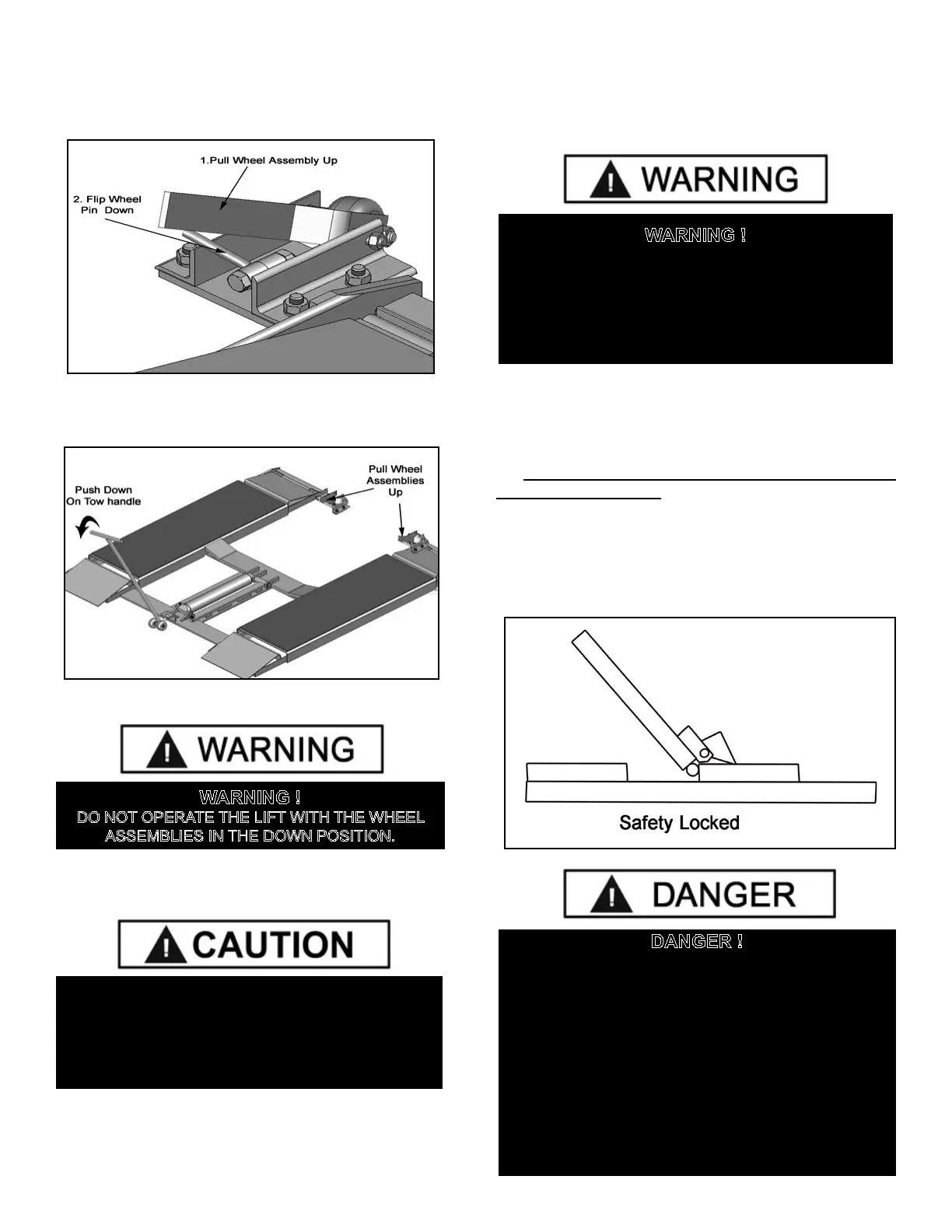

TO MOVE LIFT

1. Pull up on Wheel Assembly handle.

2. Flip Down Wheel Pin. (See Fig. 8.5)

3. Insert the Tow Handle into the Tow Handle Anchor

and push down on the Tow Handle to raise the Lift

Assembly off the ground. (See Fig. 8.6)

4. Remove the Tow Handle and Lower the Rear Wheel

Assemblies.

STEP 9

(Lift Start Up / Final Adjustments)

1. Confirm the Power Unit reservoir is full with 6 quarts/

1.5 gals of 10-WT hydraulic oil or Dexron-III automatic

transmission fluid.

2. Test the Power Unit by pressing the push-button

switch. If the motor sounds like it is operating properly,

raise the lift and check all hose connections for leaks. If

the motor gets hot or sounds peculiar, stop and check all

electrical connections.

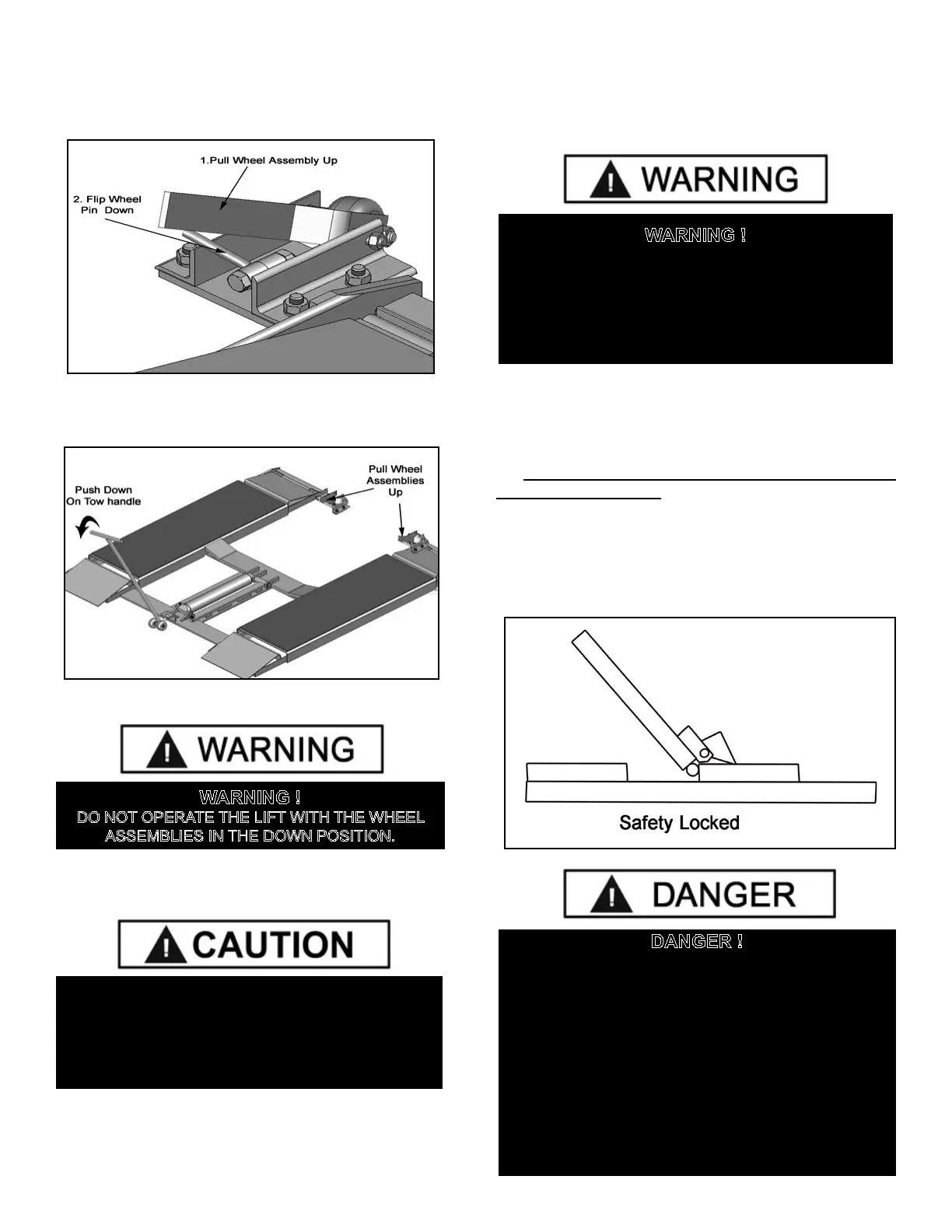

3. Check the MAIN SAFETY LOCK to make sure it

moves freely. Lubricate all SAFETY PIVOT points with

WD-40 or equal.

4. RAISE LIFT UNTIL THE CYLINDER BOTTOMS OUT

AND THE LIFT STOPS.

5. Lower the lift until the Safety rests In the Locked

Position.

6. Verify that the Safety rests in the locked position at

each safety stop. (See Fig. 9.1)

Fig. 8.6

Fig. 8.5

CAUTION!

During the START-UP procedure, observe all operat-

ing components and check for proper installation and

adjustment. DO NOT attempt to raise vehicle until a

thorough operational check has been completed.

WARNING !

KEEP HANDS AND FEET CLEAR. Remove hands and

feet from any moving parts. Keep feet clear of lift when low-

ering. Avoid pinch points.

ALWAYS WEAR SAFETY GOGGLES

DANGER !

VISUALLY CONFIRM THAT ALL PRIMARY

SAFETY LOCKS ARE ENGAGED BEFORE

ENTERING WORK AREA.

Suspension components us on this lift are intended to

raise and lower lift only and are not meant to be load

holding devices. Remain clear of elevated lift unless

visual confirmation is made that all primary safety locks

are fully engaged and the lift is LOWERED onto the

safety locks, Refer to installation /operation manual for

proper safety lock procedures

and /or further instruction.

Fig. 9.1

WARNING !

DO NOT OPERATE THE LIFT WITH THE WHEEL

ASSEMBLIES IN THE DOWN POSITION.

Loading...

Loading...