19

4. Push LOWERING valve handle to lower. Do not

override self-closing lift controls.

5. Remain clear of lift when lowering vehicle. Observe

pinch point warning decals.

6. Remove adapters from under vehicle and arms to full

drive-thru position before moving vehicle.

7. If lift is not operating properly, Do Not use until

adjustment or repairs are made by qualied lift service

personnel.

MAINTENANCE INSTRUCTIONS

• Always keep bolts tight. Check periodically.

• Always keep lift components clean.

• Always if oil leakage is observed, call local service

representative.

• Always if electrical problems develop, call local

service representative.

• Always replace ALL FAULTY PARTS before lift is

put back into operation.

• Daily: Make a visual inspection of ALL MOVING

PARTS and check for excessive signs of wear.

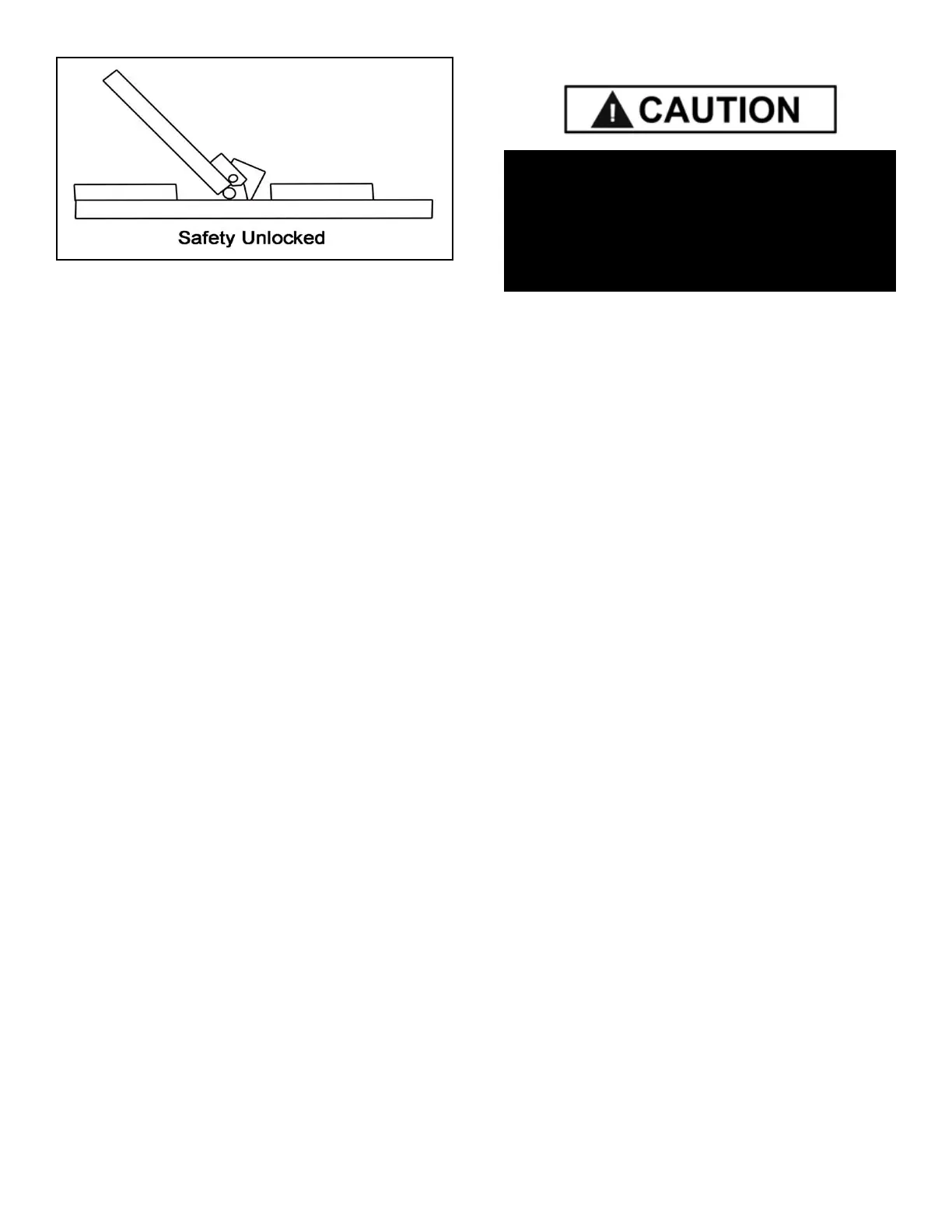

• Daily: Check Safety Locks to insure they are in good

operating condition.

• Daily: Check pivot points and hinges for wear.

Replace worn parts as required with genuine

BendPak parts.

• Daily: Inspect adapters for damage or excessive

wear. Replace as required with genuine BendPak

parts.

• Weekly: Lubricate any rollers with general purpose

oil or WD-40. Lubricate arm Hinge Pins with grease.

• Weekly: Check bolts and pins to insure proper

mounting.

• Monthly: Lubricate locking latch shafts. Push latch

handle several times for oil to penetrate pivot points.

• Every 3 Months: Check anchor bolts for tightness.

Anchors should be torqued to 90 ft/lbs.

• Semi-Annually: Check uid level of lift power unit and

rell if required per lift installation instructions.

• Replace all caution, warning or safety related decals

on the lift if unable to read or missing. Reorder labels

from BendPak.

• Refer to ANSI/ALI ALOIM booklet for periodic

inspection checklist and maintenance log sheet.

CAUTION!

If you are not completely familiar with automotive lift

maintenance procedures; STOP: Contact factory for

instructions. To avoid personal injury, permit only

qualied personnel to perform maintenance on this

equipment.

Loading...

Loading...