BestCode Next Series 8 Technical Manual October 2022 Page 267 of 290

throughout the variable speeds of the line.

Setting up Time of Flight

1. To ensure print placement accuracy when using a

Photo Eye (Non AutoPrint modes), it is important

to set up the time of flight value.

See Time of Flight for setup values based on Printhead

Distance to product.

Troubleshooting

Missed Encoders

Missed encoders occur when the speed demands of the line exceed the print capability of the printer. However, this

can accidentally occur in some circumstances. This can cause variations in print width and location up to 5%, which is

unacceptable in most Meter Marking type applications.

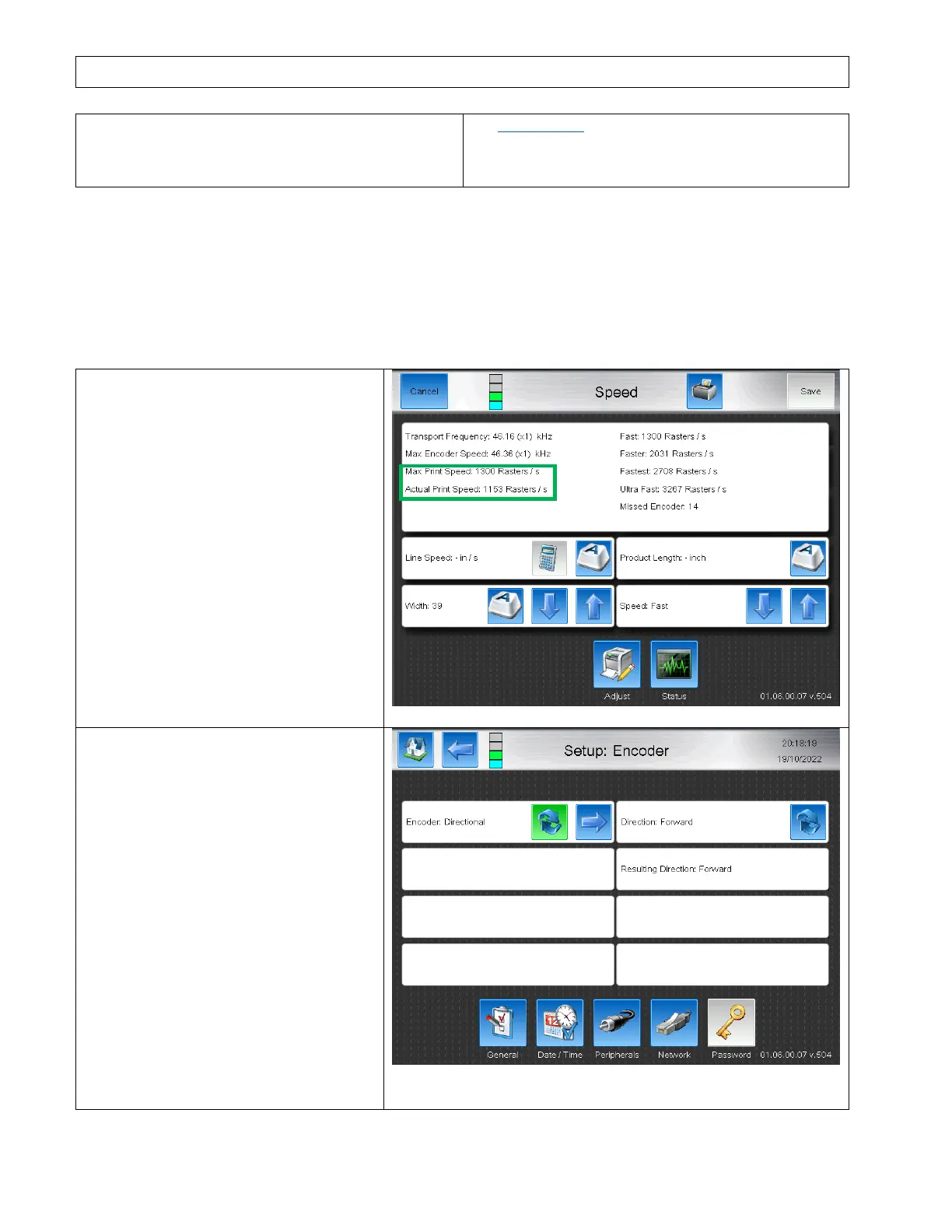

1. The use of a shaft encoder can impact

some Templates by reducing the

maximum speed by up to 10%. It is

recommended first if Missed Encoders

are occurring to set the width value so

the Actual Print speed is only 90% of the

Max Print Speed.

Example shows 1153 / 1300 * 100 =

88.7%

2. If missed encoders still occur after

reducing the “Actual Print Speed”, the

cause of the Missed Encoders may be

rigidity issues with the mechanical

coupling of the Shaft Encoder to the

conveyor.

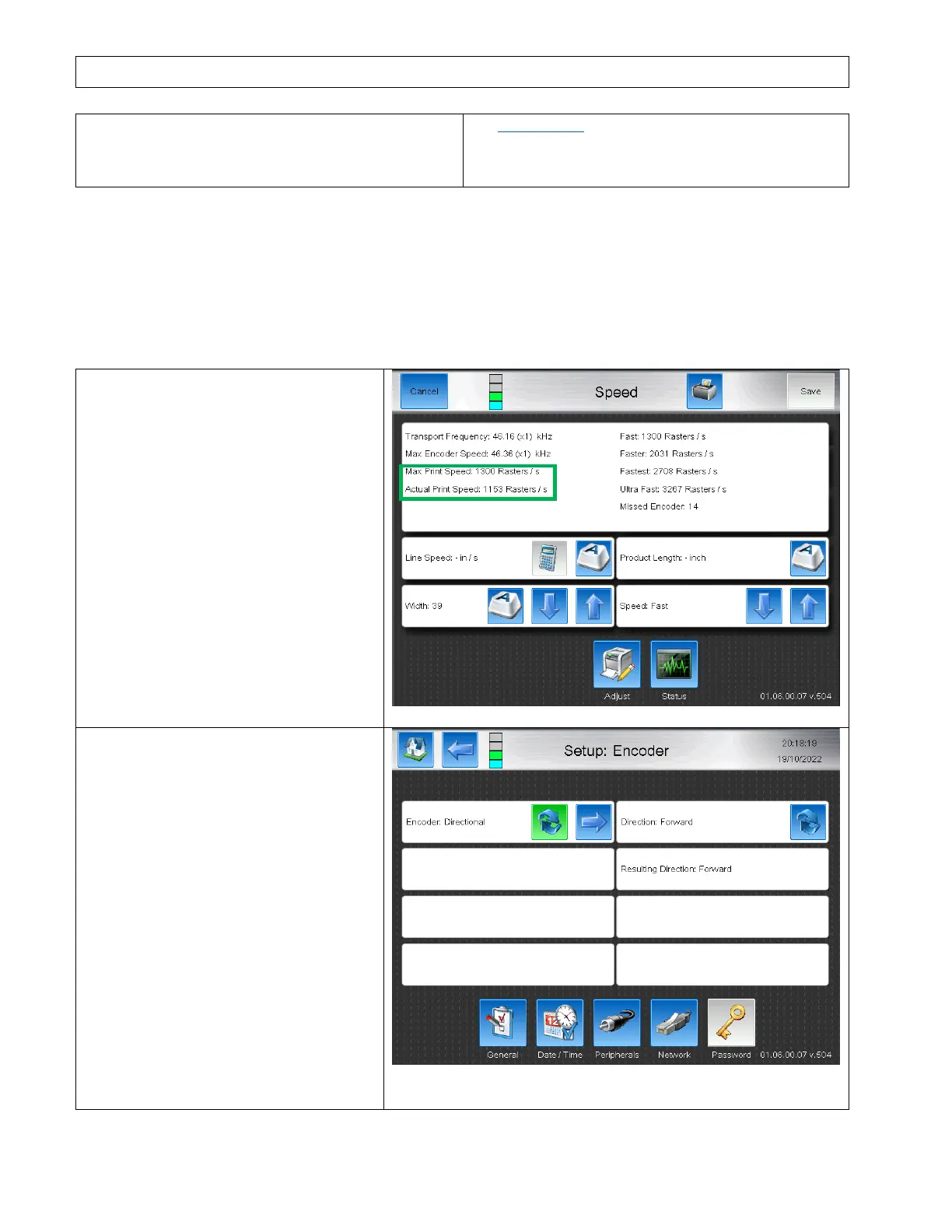

3. Set the Encoder mode to Directional to

help smooth the encoder signal.

If this does not eliminate the occurrence

of Missed Encoders, re-evaluate the

Shaft Encoder coupling method to use a

higher input frequency and use a larger

width value to help smooth the encoder

input speeds.

Loading...

Loading...