46

July 2020

Installation, Operation and Maintenance Manual

MAN616_EAC Rev. 5

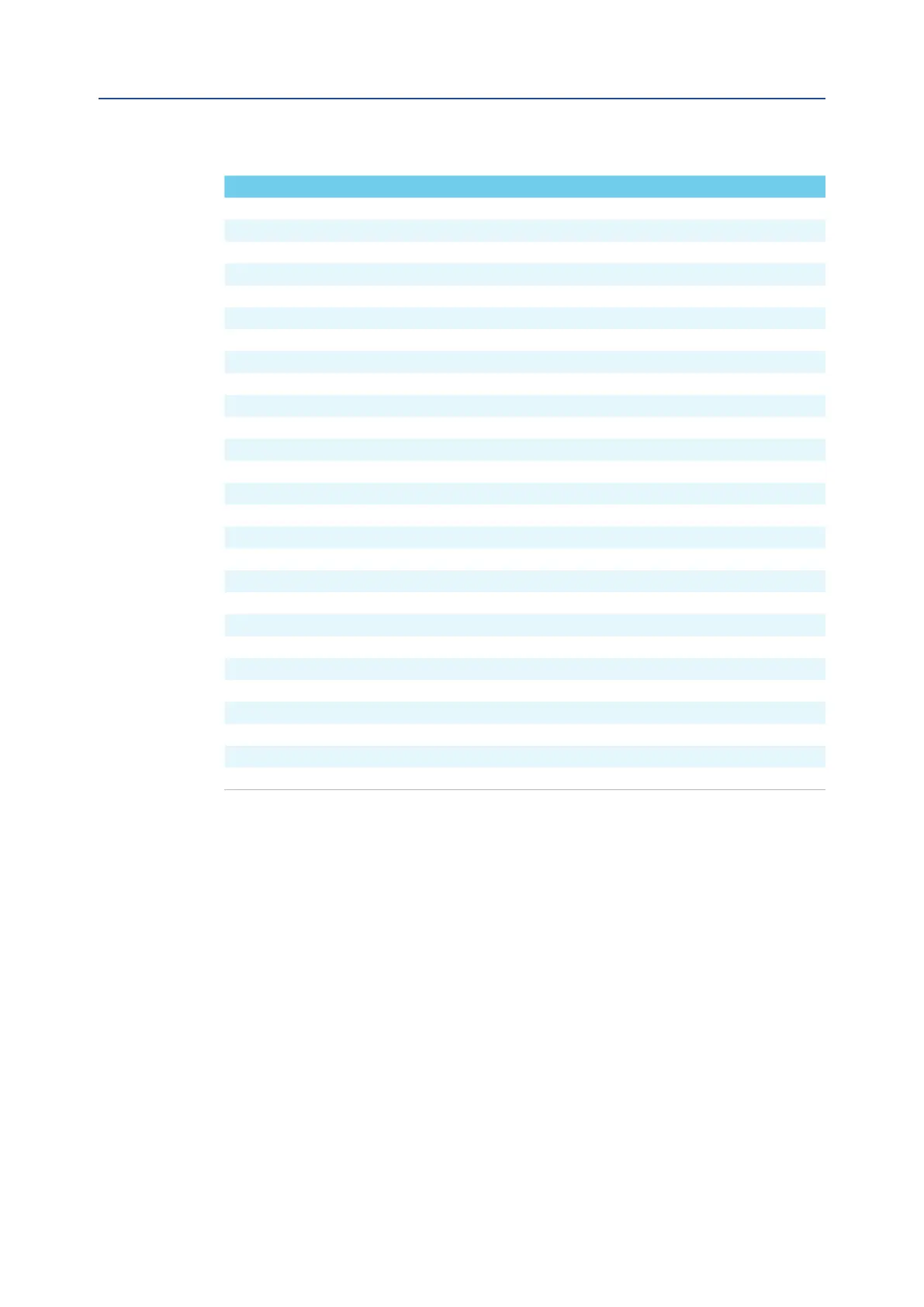

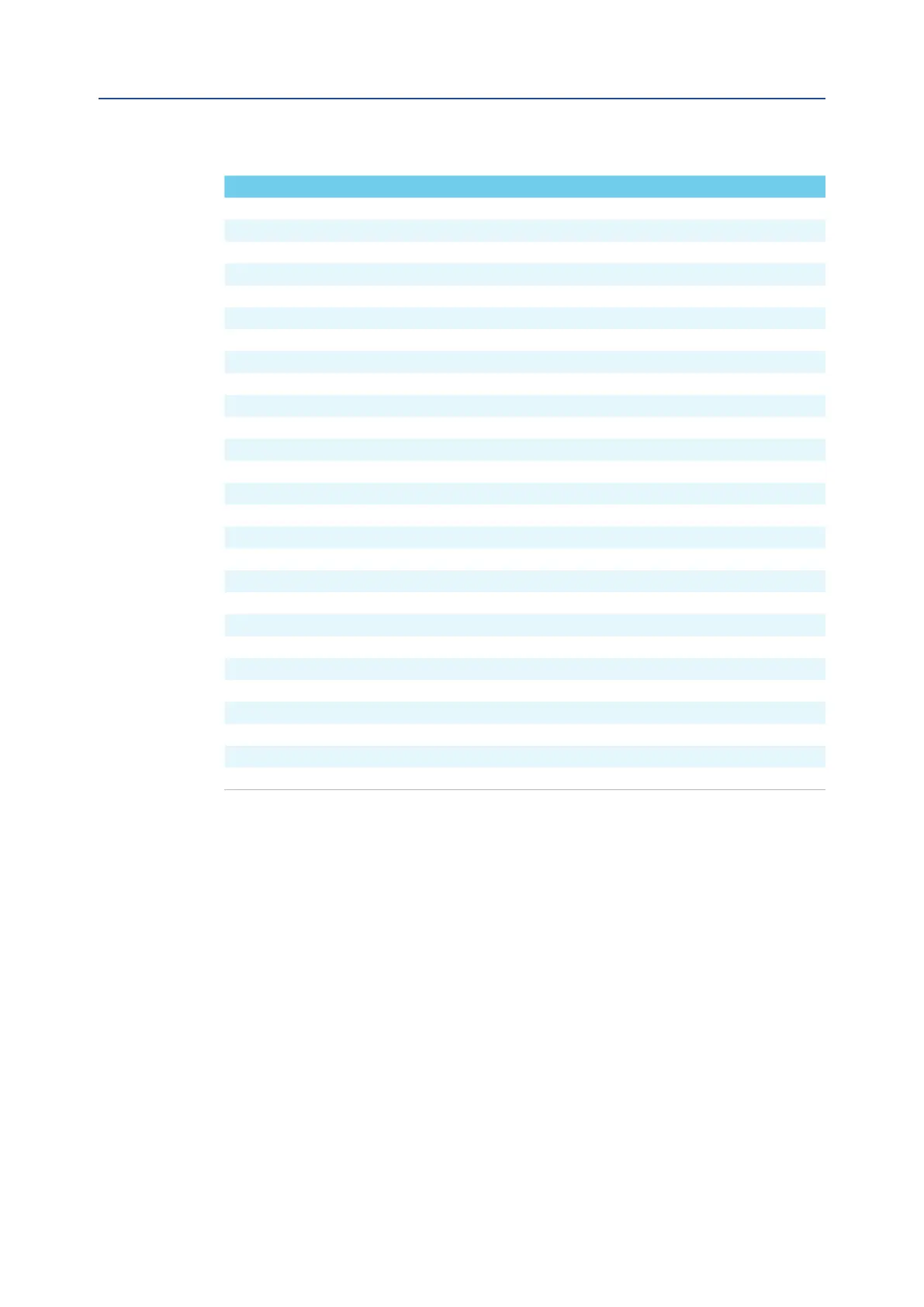

Layouts and Sectional Drawings

Section 7: Layouts and Sectional Drawings

NOTE:

* recommended spare parts

Item Qty Description Material

1 4 Spacer Stainless steel

2 1 O - ring * Viton

3 1 Piston ring nut Stainless steel

4 1 Piston Aluminium

5 1 O - ring * Viton

6 1 Filter Stainless steel

7 1 Body Stainless steel

8 2 O - ring * Viton

9 1 Spring Spring steel

10 1 Sealing washer * PVC

11 2 Screw Stainless steel

12 1 Nut Stainless steel

13 1 Screw (adjustable) Stainless steel

14 4 Screw Stainless steel

15 1 Plug Stainless steel

16 1 Spacer Stainless steel

17 4 Screw Stainless steel

18 1 Washer Stainless steel

19 1 Cover Stainless steel

20 2 Screw Stainless steel

21 2 Spacer Stainless steel

22 2 O - ring * Viton

23 2 O - ring * Viton

24 2 O - ring * Viton

25 4 Washer Stainless steel

26 2 Ring nut Stainless steel

27 2 Flow control screw Stainless steel

Table 17. Parts List

Loading...

Loading...