Pressure setting method: force controlled setting

In the stroke setting method, the tool delivers a constant stroke. When

there is a variation in thickness of the workpiece there is a definite risk

that a blind rivet nut may not be set properly, or become damaged due

to the setting mandrel damaging the RIVKLE

®

thread. In this situation

there will be premature wear of the mandrel.

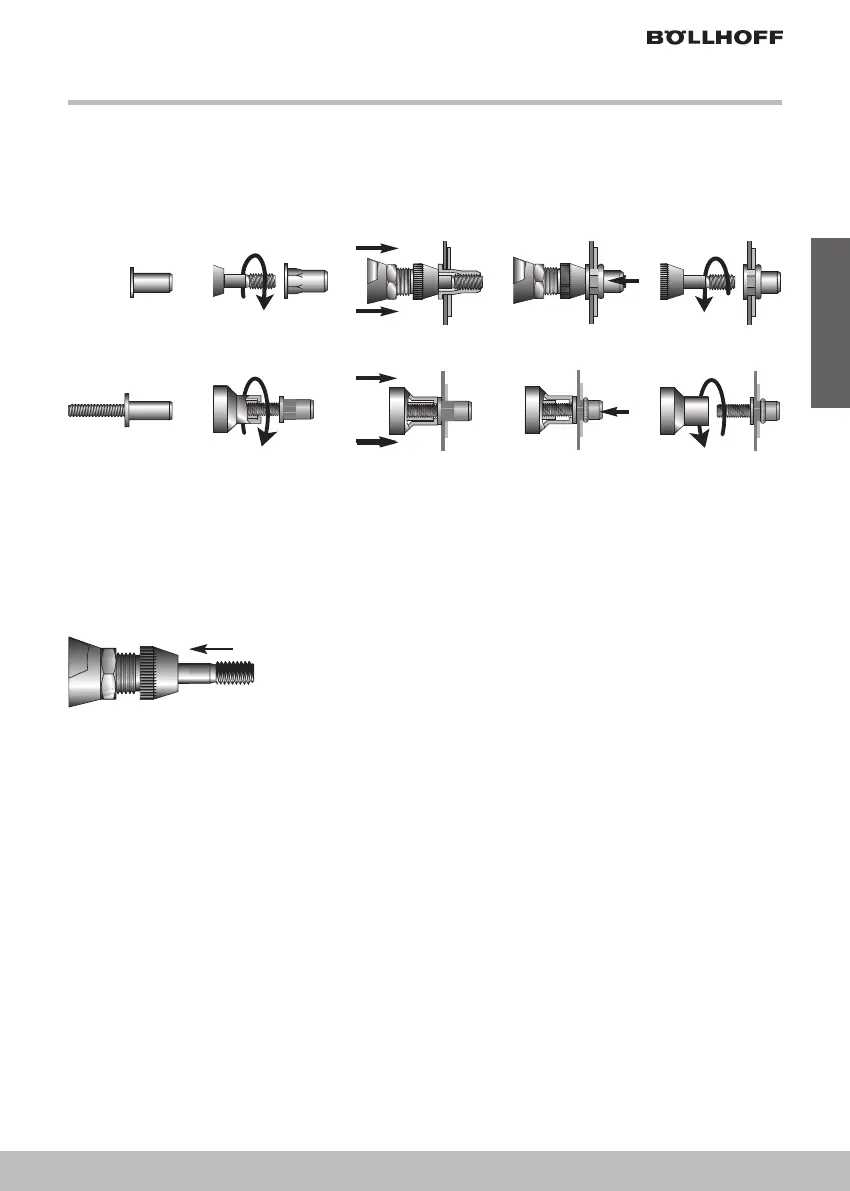

This phenomenon is eliminated with the pressure setting method as the

setting force is controlled irrespective of the thickness of the workpiece.

This setting principle is particularly well suited to workpieces with variable thickness (plastic parts,

various layers…) and provides consistent setting quality.

Advantages:

! Optimised setting into panels with thickness variations

! Possibility to set the same RIVKLE

®

more than once

! Permits quality control (force indicator…)

! Extended mandrel life

! Can also set different types of RIVKLE

®

with one tool and one single setup

English

31

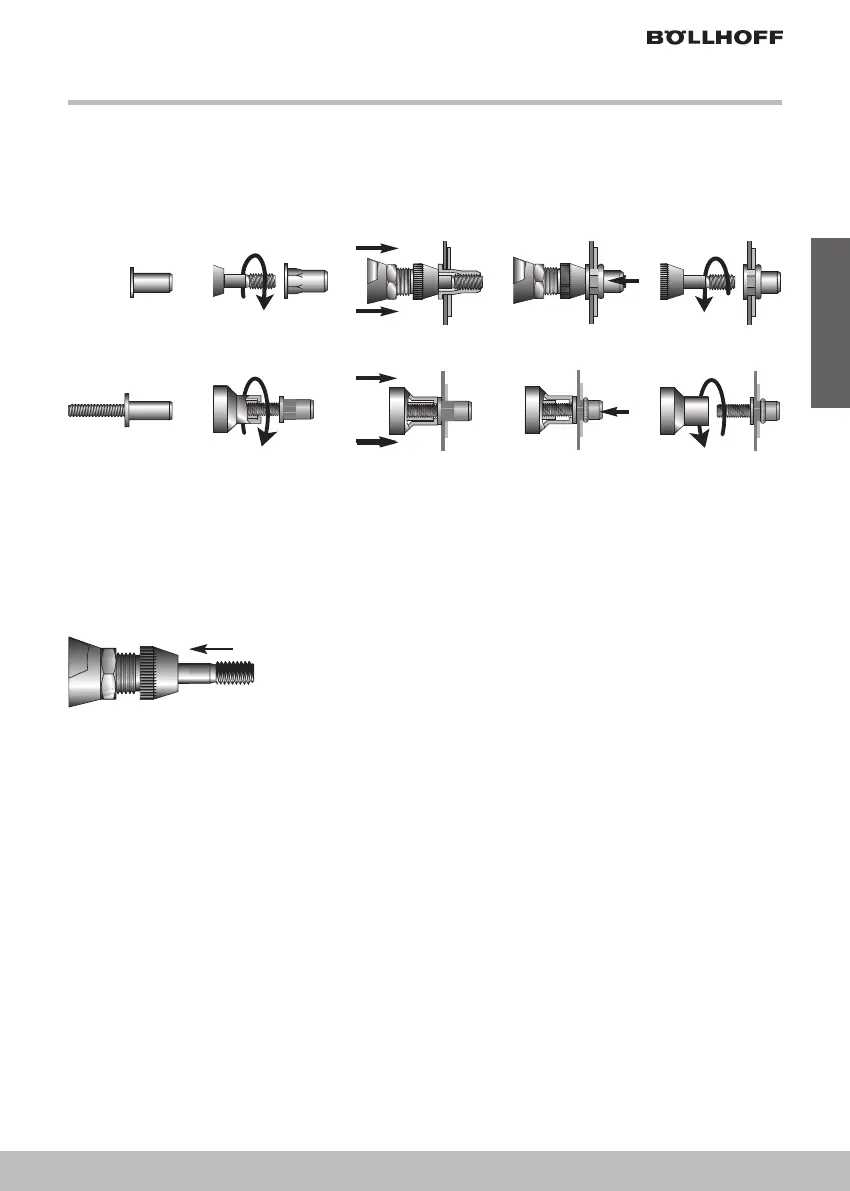

1 - Operating principle and technical features of the device

Crimp Spin off

Spin on

Insert

Setting methods

The “setting method” comprises ! Spin on, " Insert, # Crimp and $ Spin off cycles.

F

! " # $

Loading...

Loading...