48

5. Repair

! When tightening screws with a cutting edge the fol-

lowing procedure must be observed:

1. Lightly oil threaded screw.

2. Tighten screwed connection to 70 Nm.

3. Turn screwed connection back through 90°.

4. Tighten screwed connection to 100 Nm.

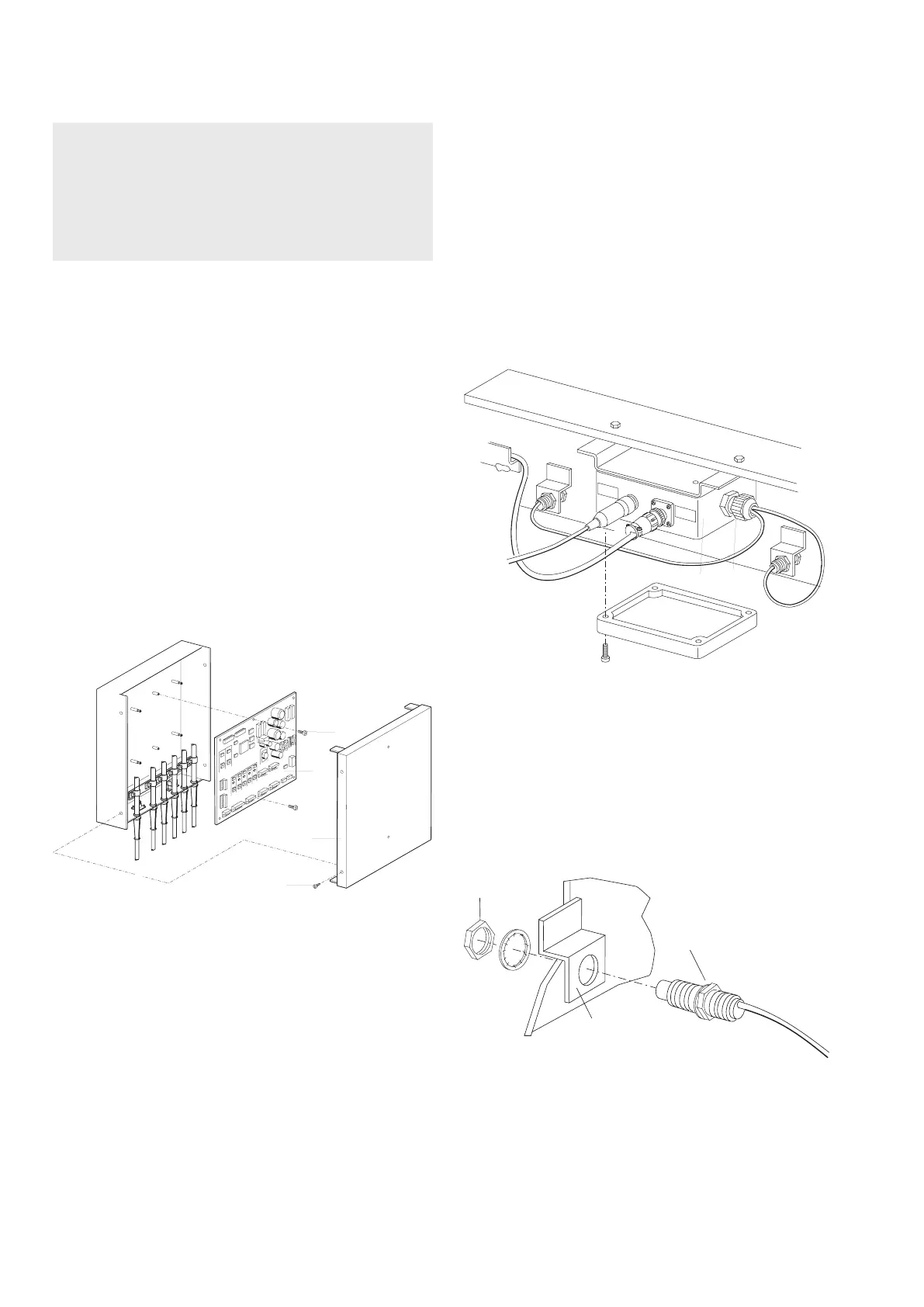

5.1 Replacing A10 control printed circuit board

Procedure:

1. Switch off EPS on main switch.

2. Remove fastening screws (1).

3. Remove housing cover (2).

4. Detach all connecting cables from printed circuit

board.

5. Remove both fastening screws (3).

6. Detach printed circuit board (4) from spacer clips.

7. Plug in new printed circuit board to spacer clip.

i The spacer clips lose their clamping effect when PCBs

are frequently plugged in. In such a case use a screwdri-

ver to slightly force the spacer clips apart when the PCB

is plugged in.

8. Mount individual components in reverse dismantling

order.

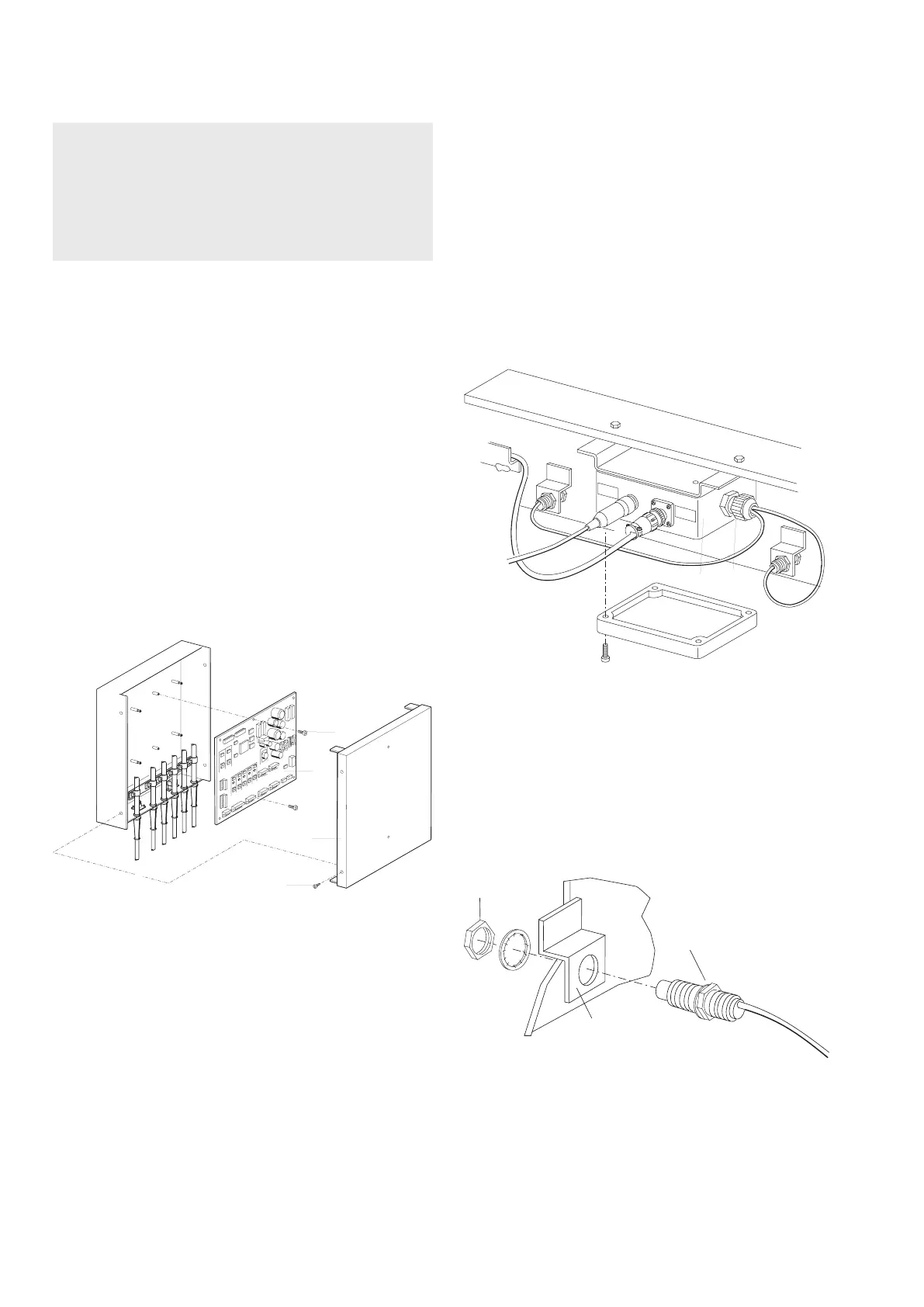

5.2 Replacing inductive proximity switch

Procedure:

1. Switch off EPS on main switch.

2. Open anti-splash guards.

3. Open terminal box (1) and disconnect electrical cable

for proximity switch (for B11 and B12 only).

i For the B13 proximity switch (at front-end door) only

the X10.2 plug connector of the terminal box need be

removed.

4. Undo cable screw connection (2) on terminal box.

5. Withdraw connecting cable from terminal box.

6. Use 17mm open end wrench to undo front hexagon

nut (3) and remove it.

7. Remove proximity switch (4) from retaining bracket

(5).

8. Mount new proximity switch to retaining bracket using

hexagon nut and toothed disk.

i Do not tighten hexagon nut.

Loading...

Loading...