14 en | Technical Specifications Aspirating Smoke Detector

2018.04 | 2.0 | F.01U.130.926 Operation Guide Bosch Sicherheitssysteme GmbH

To set the FCS-320 to the airflow typical for the pipe network, an airflow initialization (flow-

init) procedure is carried out. This must be done for each unit once at the start after

installation, each time the pipe system is replanned/redesigned and after changing the fan

voltage. This enables the unit to determine and save the airflow typical for the pipe network.

Pipe System

A pipe system with an overall length of up to 300m can be connected to FCS-320 series

aspirating smoke detectors over a maximum of 32 aspiration points. Two pipe systems can be

connected to both the FCS-320‑TP2 and FCS-320‑TT2 variants. The entire pipe system then

has a total length of 2 x 280m and a maximum number of 2 x 32 aspiration points.

3.5 FCS-320 Series Aspirating Smoke Detectors and Accessories

3.5.1 Overview

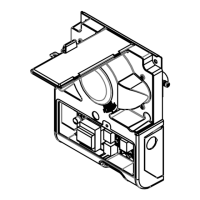

Overview of FCS-320 series aspirating

smoke detectors and accessories

1 Pipe system(s)

2 Connections to fire panel/power supply

3 Air-return pipe

A Vibration absorber (sold separately)

B MT-1 unit mounting

C Detector module

D DIAG Diagnostic Software with connection

cable

E Cable bushings (1xM20, 2xM25)

F Test pipe

G Test adapter

FCS-320 series aspirating smoke detectors comprise the following components:

– Plastic housing

– Plastic connection pieces

– Integrated air-return pipe

– Connection for pipe with 25mm external diameter

– Aspiration unit with optimized air supply

– Motherboard with interface for diagnostics system, LSN connections, connection for

shield wire, as well as DIP switch for address setting

– Supplementary package with cable bushings (1xM20, 2xM25)

– FCS-320-TP1 /FCS-320-TP2: optical displays for alarm, malfunction and operation

– FCS-320-TT1 /FCS-320-TT2: smoke level display(s), optical displays for info, pre and main

alarm, malfunction and operation

– 1 detector module (for FCS-320-TP1 and FCS-320-TT1) and/or 2 detector modules (for

FCS-320-TP2 and FCS-320-TT2).

Loading...

Loading...