108 en | Commissioning Aspirating Smoke Detector

2018.04 | 2.0 | F.01U.130.926 Operation Guide Bosch Sicherheitssysteme GmbH

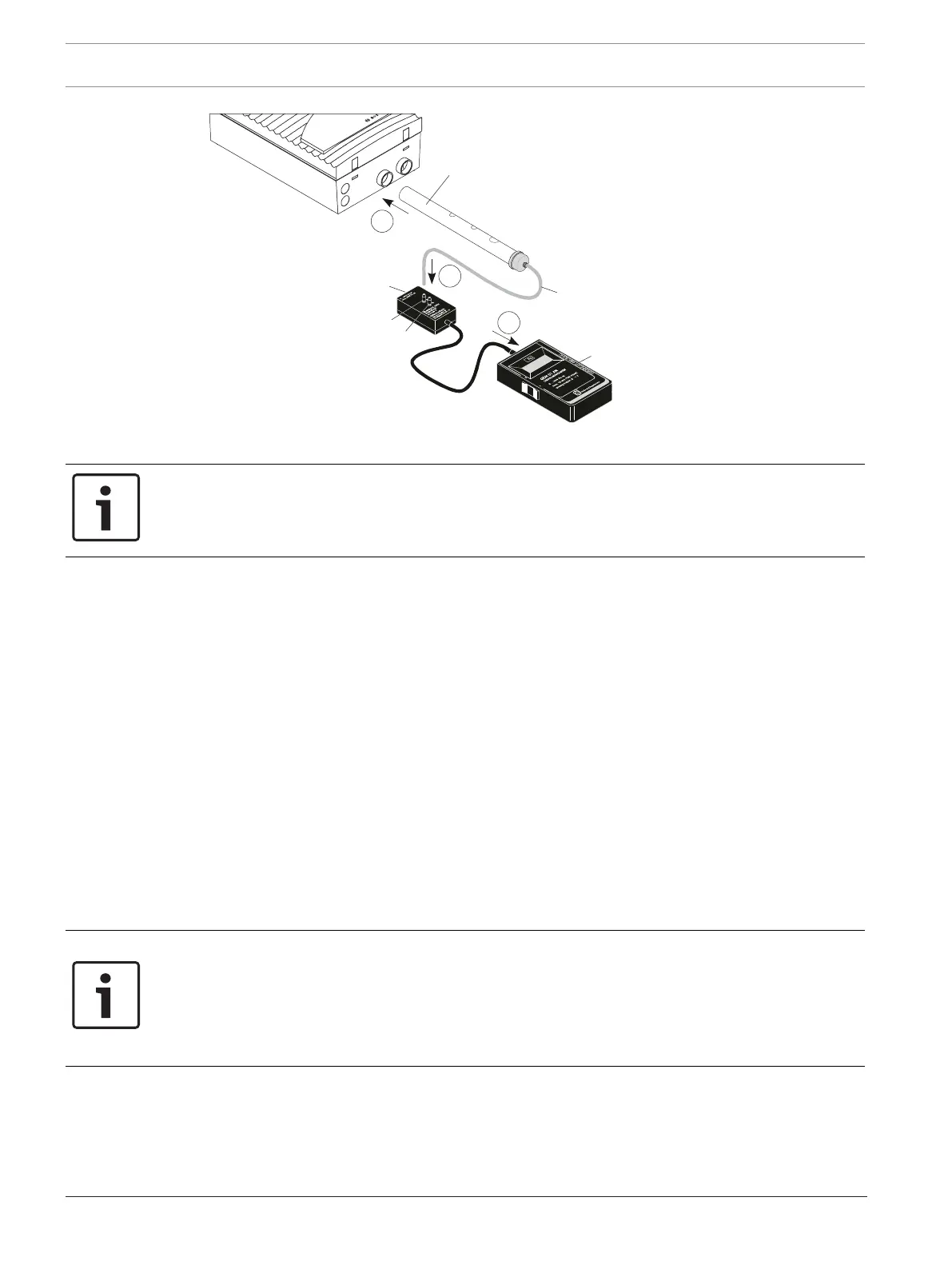

B

A

ø 7,0 mm

ø 4,2 mm

ø 4,6 mm

1

3

2

3

4

5

1

2

FAS-420 series

Testing the functionality of the FCS-320

1 Test pipe

2 Aspiration borings

3 Pressure measuring hose

4 Adapter

5 Digital pressure gauge

A/B Adapter connection

Notice!

For the FCS-320-TP2 and FCS-320-TT2, the preparation for the function test (see above) and

the following functional test (steps 1–7) are to be carried out for both detector modules and/

or both pipe systems.

7.6.2 Conducting the Functional Test

The functional test can be conducted with or without a digital pressure gauge. The complete

test is described below. If the test on the FCS-320 reveals deviations from the described

procedure, the unit or its airflow sensor is defective.

– Make sure that the aspirating smoke detector has been operating for at least 30minutes.

– Close all the test pipe’s aspiration borings with some duct tape. After a few seconds, the

LED flash code on detector module I and detector module II must signal an obstruction.

After a short run-up time, the negative pressure must lie within the following range:

– Fan voltage 6.9V: 250Pa to 310Pa

– Fan voltage 9V: 460Pa to 530Pa.

– Open all of the test pipe's aspiration borings. After a few seconds, the flash code of the

LED must go out.

– Remove the test pipe. The LED flash code on detector module I and detector module II

must signal a breakage.

– Reconnect the test pipe to the device. After a few seconds, the flash code of the LED

must go out.

Notice!

A pipe breakage or pipe obstruction is indicated by a flash code via an LED on the detector

module (see Section7.2Flash Code Table, page94):

Breakage: 3 x flashes

Obstruction: 2 x flashes

The corresponding flash code is repeated every two seconds.

DIAG diagnostic software

The DIAG Diagnostic Software can be used to track airflow values during the function test.

Save all diagnostics data as a file. To be able to compare the data read out, save each file

under a different file name.

Information for installing the diagnostic software can be found in Preparation, page 103.

Loading...

Loading...