Do you have a question about the Bosch Rexroth CKL Series and is the answer not in the manual?

Document's purpose for initial CKL linear motor module commissioning.

Steps for commissioning the CKL system.

First part of the commissioning flowchart for CKL systems.

Second part of the commissioning flowchart, specific to analog Hall sensors.

Second part of the commissioning flowchart for digital Hall or no Hall sensors.

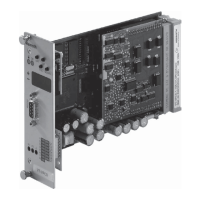

Hardware, software, and operating system requirements for CKL drive controller commissioning.

Steps to connect PC to IndraDrive for commissioning using NRT.

Detailed steps for configuring network connection for IndraDrive.

Verifying firmware compatibility and updating procedures.

Procedures for updating the drive's firmware.

How to select language for drive interface elements.

Setting up master communication for Multi-Ethernet IndraDrive.

Steps to configure the IndraDrive's power supply.

Steps to configure scaling and mechanical system settings.

Setting up software and hardware limit switches.

Setting torque and force limits for the drive.

Steps to update the motor database.

Configuring linear motor parameters from the database.

Setting continuous current for CKL linear motor.

Steps to configure motor encoder parameters.

Steps to configure data reference for the motor encoder.

Loading standard control loop parameters for CKL systems.

Steps for configuring commutation settings with Hall sensors.

Steps to enable and start easy startup mode.

Example procedure for fixing drive errors.

Additional methods for drive error diagnostics.

Procedure to determine commutation offset.

Steps to enable drive power.

Method to verify commutation offset.

Steps for drive-controlled homing.

Procedure to stop initial commissioning mode.

Steps for saving parameters to a PC.

Testing axis movement with jogging or profiles.

Procedures for optimizing control loops.

| Series | CKL |

|---|---|

| Category | Controller |

| Manufacturer | Bosch Rexroth |

| Protection Class | IP20 |

| Voltage Range | 24 V DC |

| Storage Temperature | +70°C |

| Communication Interface | Ethernet |