Do you have a question about the Bosch Rexroth CS 440RC and is the answer not in the manual?

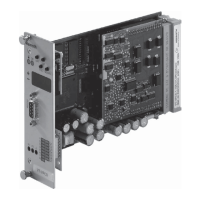

Describes the layout of the CS-440RC controller's front panel and its controls.

Illustrates a standard solid de-icer system configuration, detailing its components.

Details the components and setup of a typical pre-wetting system.

Provides general instructions for configuring the CS-440RC system, including accessing menus.

Explains how to restore the controller to its factory default settings.

Guides on assigning unique identifiers for the controller's location and the truck.

Guides on selecting measurement units (metric or imperial) for the system.

Explains how to configure different conveyor control modes like Automatic, Manual, etc.

Instructions for setting the system's date and time parameters.

Details how to activate and configure the GPS functionality for the system.

Introduces the concept of ground speed sensing and its importance for the CS-440RC.

Describes manual calibration by driving over a known measured distance.

Explains auto-calibration using an external handheld GPS device for speed.

Details auto-calibration using the vehicle's integrated GPS signal.

Describes auto-calibration using the vehicle's speedometer.

Provides the step-by-step procedure for performing auto-calibration.

Guides on how to verify and adjust the ground speed calibration.

Explains how to use simulated ground speed for testing and setup.

Explains the process of nulling valve solenoids for efficient conveyor operation.

Guides on setting the minimum amperage output for conveyor valve solenoids.

Details setting the maximum amperage output for conveyor valve solenoids.

Explains the automated process for nulling conveyor solenoids.

Discusses the Forward Gain setting to overcome motor pulsing issues.

Guides on configuring the number of pulses per revolution for the conveyor speed sensor.

Explains how to choose the operational mode for the gate (Off, Read Back, Closed Loop).

Details the calibration process for the gate's read-back sensor.

Describes the setup and operation of the closed-loop gate function.

Instructions for naming different solid and liquid materials used in the spreader.

Guides on setting specific spread rates for different materials.

Outlines the general procedure for material calibration.

Explains how to set the gate position for material calibration.

Details the automated process for calibrating material spread rates.

Describes how to verify calibration using simulated ground speed.

Explains how to select the operational mode for the spinner (Manual, PPS).

Guides on configuring the spinner's stop behavior (Always On, Zero Speed, Pause).

Details how to adjust the spinner speed for optimal spreading.

Explains the process of nulling spinner solenoid outputs.

Guides on setting the minimum output for spinner solenoids.

Details setting the maximum output for spinner solenoids.

Explains the automated process for nulling spinner solenoids.

Describes settings related to the Positive Placement System for the spinner.

Guides on configuring spinner sensor pulses per revolution.

Details setting the maximum RPM for the spinner motor.

Explains how to set the PPS Factor for the spinner.

Guides on calibrating the spinner in gm/mm2 mode.

Explains how to select the operational mode for the pre-wetting system (Off, Fixed, Closed Loop).

Guides on setting solid reduction rates when liquid is applied.

Instructions for naming liquid materials used in the pre-wetting system.

Guides on setting spread rates for pre-wetting liquids.

Explains the process of nulling pre-wetting valve solenoids.

Guides on setting minimum output for pre-wetting valve solenoids.

Details setting maximum output for pre-wetting valve solenoids.

Explains the automated process for nulling pre-wetting solenoids.

Guides on performing automatic calibration for the pre-wetting system.

Explains the operation and setup of the simulated anti-icing mode.

Guides on selecting the simulated anti-icing mode.

Details how to configure the system for simulated anti-icing.

Instructions for changing liquid settings to PREWET.

Guides on entering pre-wetting liquid rates.

Instructions for changing liquid settings to ANTI-I.

Guides on entering anti-icing liquid rates.

Details the setup for multi-boom anti-icing systems.

Guides on selecting the multi-boom anti-icing mode.

Details system configuration for multiple boom anti-icing.

Instructions for changing liquid 3 settings to ANTI-I for multi-boom.

Guides on entering anti-icing liquid rates for multi-boom.

Explains how to select the blast mode for solid de-icing (Max Output, Stationary).

Guides on setting blast mode for fixed ratio pre-wetting.

Details how to configure the auto-off timer for the blast function.

Guides on setting the maximum blast rate for the conveyor.

Explains how to set the blast rate in closed-loop mode.

Guides on setting a default gate opening for operator selection.

Explains how to preset material selection options for the operator.

Guides on setting pre-wet selection options for the operator.

Details how to configure general operator options and modes.

Explains how to clear the season total data.

Guides on configuring the high speed alarm threshold.

Explains how to select the type of temperature sensor installed.

Guides on configuring temperature compensation for application rates.

Lists and explains operational error messages and their causes.

Lists and explains errors related to system inputs and outputs.

Guides on setting time delays for error message activation.

Explains how to configure the system's response to errors.

Addresses common questions regarding the CS-440RC controller.

Explains the meaning of headers used in log data reports.

Defines how to calculate spreading time from event reports.

Clarifies the meaning of 'Total Time' in event reporting.

Lists and explains the CS-440RC error codes and their messages.

Explains the unit toggling for Total Distance in Trip Summary.

Guides on checking the operational modes of various system components.

States the default password for the system.

Explains how to set up and use the simulated ground speed feature.

Lists and describes the available modes for the BLAST function.

Explains the functionality and setup of the SOLID REDUCTION feature.

Explains the RETURN OIL PREWET system.

Discusses different methods for calibrating the vehicle's ground speed.

Guides on setting up or nulling min/max outputs for conveyor valves.

Details setting up or nulling min/max outputs for spinner valves.

Explains setting up or nulling min/max outputs for prewet/liquid pumps.

Addresses engine RPM requirements for nulling procedures.

Lists the types of temperature sensors supported by the controller.

Details the pin assignments for the CS-440RC digital inputs.

Provides troubleshooting steps for a blank display screen.

Troubleshooting steps for a conveyor that fails to start or run.

Troubleshooting steps for a spinner that fails to start or run.

Troubleshooting steps for a dump body that fails to raise.

Troubleshooting steps for slow hydraulic functions.

Troubleshooting steps for hydraulic functions that do not shut off.

Troubleshooting steps for a hydraulic system that is overheating.

Troubleshooting steps for hydraulic oil that is milky or foaming.

| Brand | Bosch |

|---|---|

| Model | Rexroth CS 440RC |

| Category | Controller |

| Language | English |