F 002 DG9 H10 2018-08-21| Bosch Automotive Service Solutions GmbH

10 | RG8.0 / RG4.0 | Troubleshootingen

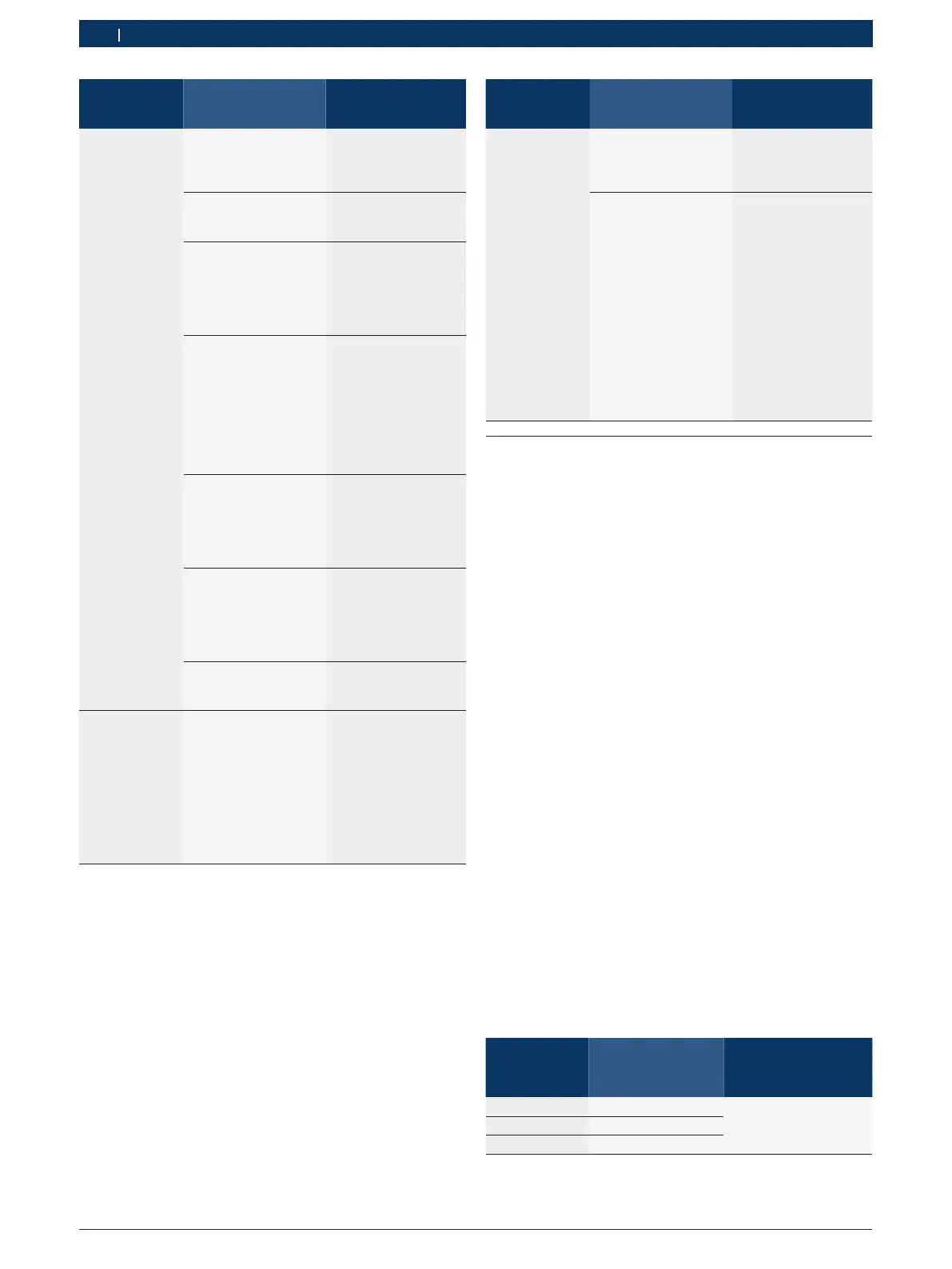

Symptom /

Problem

Checklist Cause/Action

RG8.0 / RG4.0

does not start

/ run when the

main switch is

in turned on.

Is the RG8.0 / RG4.0

plugged into the cor-

rect voltage and fre-

quency source?

Verify power to

RG8.0 / RG4.0

Is there power at the

outlet / mains source?

Verify power to

RG8.0 / RG4.0

Has the circuit

breaker tripped?

R Reset the

circuit breaker.

R If the circuit break-

er cannot be re-

set, replace the

circuit breaker.

Does the blue

gauge read 0 or

less pressure?

LP cut-out triggered.

R Clean or replace

the particle fil-

ter in inlet port of

RG8.0 / RG4.0 (re-

fer chapter 6.19).

R Raise inlet pres-

sure by opening

the inlet valve.

Does the red gauge

show a value great-

er than 38.5 bar?

HP cut-out trig-

gered. Release the

pressure carefully.

The RG8.0 / RG4.0

should restart after

relieving pressure.

Check for physical

damage or loose con-

tacts in

internal wiring.

Refer to the electrical

diagrams in chapter 7.

Open the LH and RH

enclosure. Rectify the

loose connections.

Or

Replace the wir-

ing harness.

Perform test to locate

defective component

Refer chapter 5.2.

Replace the defec-

tive component.

The

RG8.0 / RG4.0

does not

pull down in-

to vacuum.

Perform internal leak

test as described

in chapter 5.3.

If the leak test

fails, rectify the

leak or replace the

faulty tubing.

or

Replace the seals

in the manifold.

or

Replace the

manifold assembly.

Symptom /

Problem

Checklist Cause/Action

Poor

recovery rate

or

The

RG8.0 / RG4.0

does not pump

up to 38.5 bar.

Check if the parti-

cle filter in inlet port

of the RG8.0 / RG4.0

is clogged.

Clean or replace the

clogged particle filter.

Refer chapter 6.19.

Perform internal leak

test as described

in chapter 5.3.

If leak test fails, recti-

fy the leak or replace

the faulty tubing.

or

Replace the seals

in the manifold.

or

Replace the man-

ifold assembly.

or

Compressor seals

worn out: In-

stall a new com-

pressor kit or re-

place compressor.

5.2 Diagnosing component failure

5.2.1 Of circuit breaker

1. Execute the steps listed in chapter 3.1.

2. Unfasten the screws of the LH and RH enclosures

(Fig. 3, Pos. 6, 18) / (Fig. 4, Pos. 6, 19).

3. Disconnect the electrical connections to the circuit

breaker.

4. Using a multimeter, check the continuity between

the terminals of the circuit breaker.

5. If continuity exists, the circuit breaker is functional.

Else, replace the circuit breaker.

5.2.2 Of HP / LP switch

1. Execute the steps listed in chapter 3.1.

2. Unfasten the screws of the LH and RH enclosures

(Fig. 3, Pos. 6, 18) / (Fig. 4, Pos. 6, 19).

3. Disconnect the electrical connections to the HP / LP

switch.

4. Using a multimeter, check the continuity between

the terminals of the HP / LP switch.

5. If continuity exists, the HP / LP switch is functional.

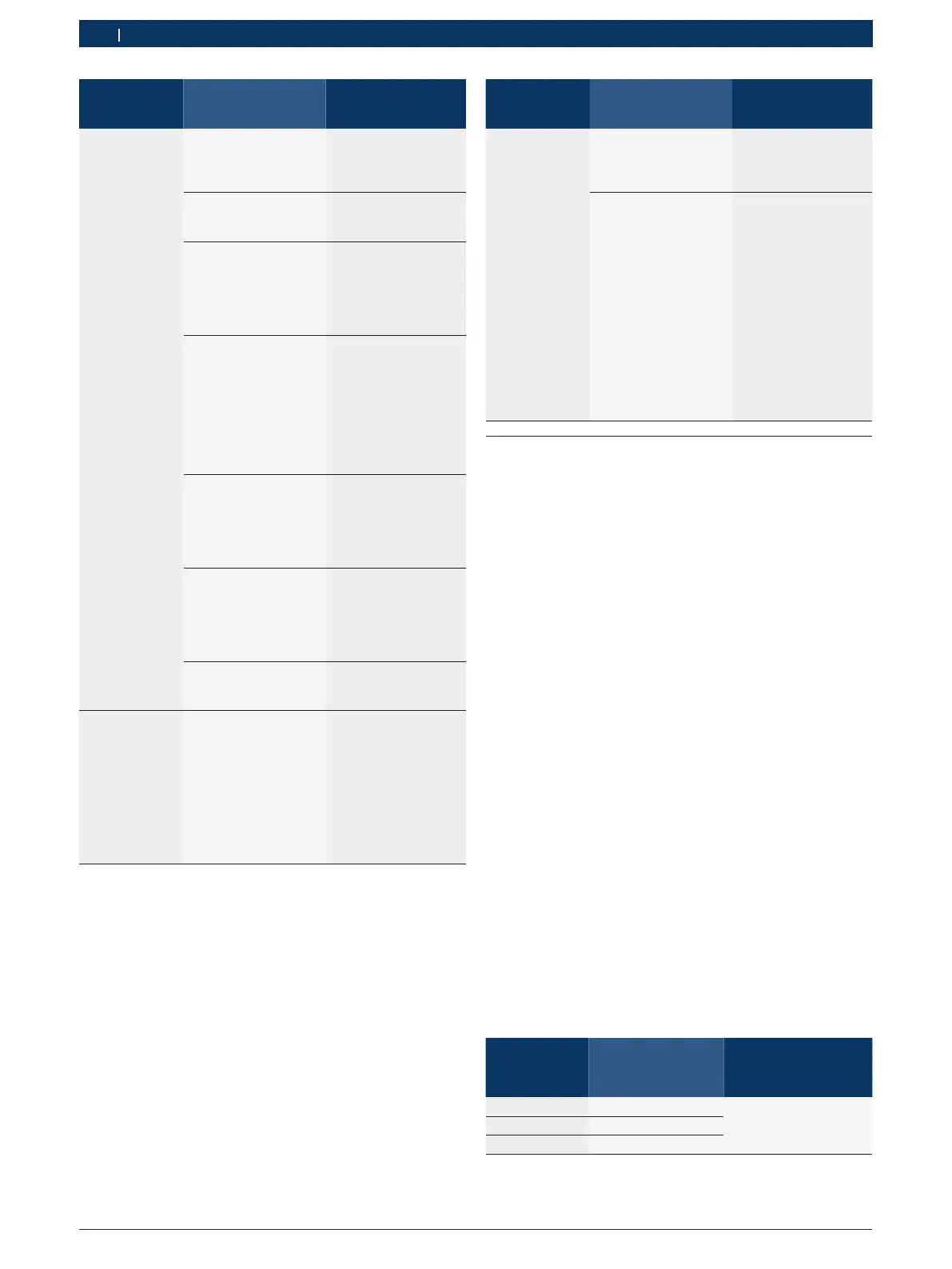

5.2.3 Of start relay (for RG8.0)

1. Execute the steps listed in chapter 3.1.

2. Unfasten the screws of the LH and RH enclosures

(Fig. 3, Pos. 6, 18) / (Fig. 4, Pos. 6, 19).

3. Disconnect the electrical connections to the relay.

4. Check the continuity and execute action as listed in

the following table:

Continuity

between

terminals...

Result Action

4 and 3 No continuity

Replace relay4 and 2 Continuity observed

3 and 2 Continuity observed

Loading...

Loading...