F 002 DG9 H10 2018-08-21| Bosch Automotive Service Solutions GmbH

Overview of parts | RG8.0 / RG4.0 | 9

en

4.4 Additional parts / kits

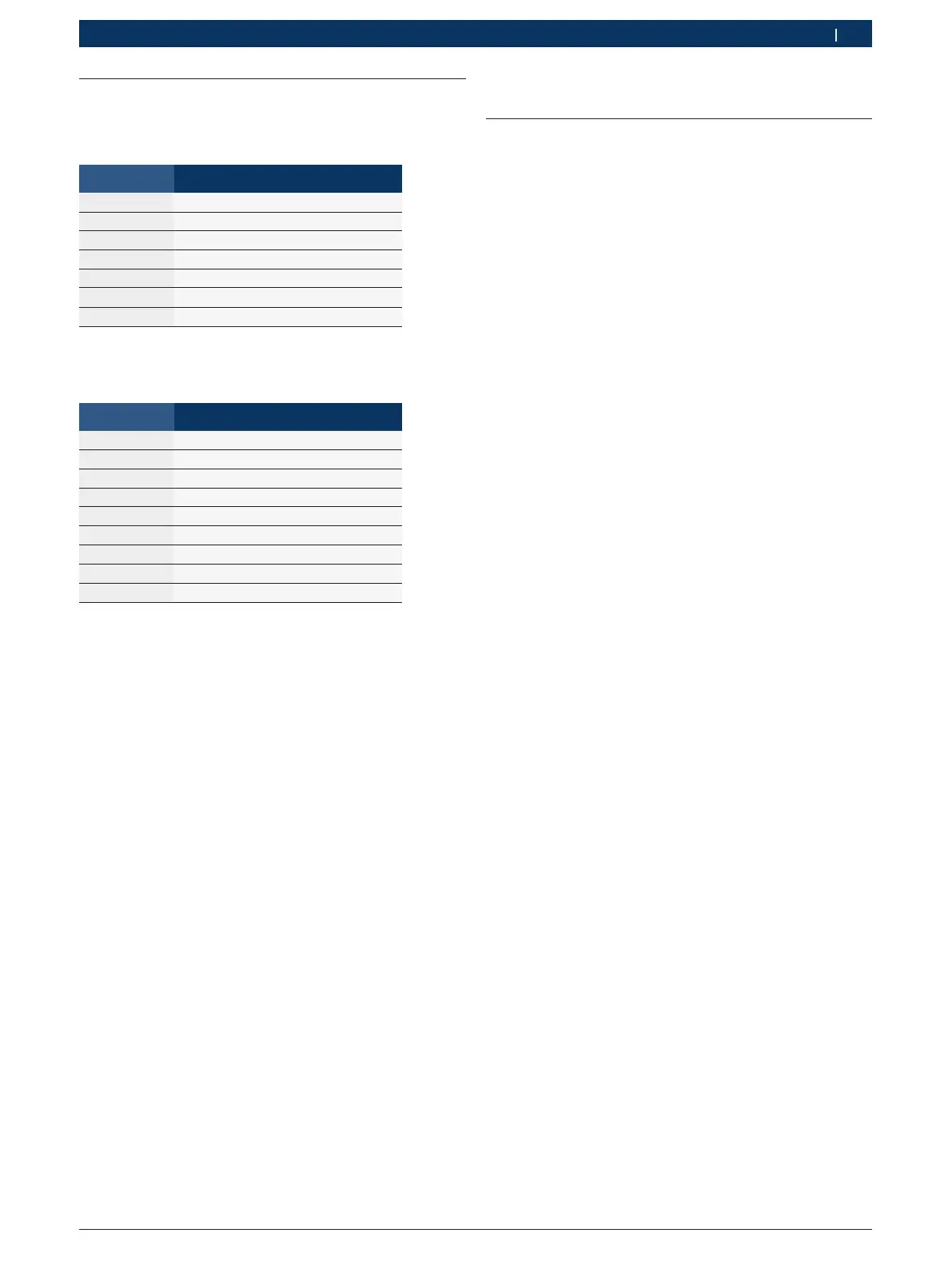

4.4.1 For RG8.0

Part number Part Description

RGB800230 Valve repair kit

RGB800240 Compressor repair kit

RGB800250 Piston replacement kit

RGB480270 Filter drier

RGB480280 Filter hose

RGB480290 Filter / Hose kit

RGB480300 Inlet fitting with filter screen

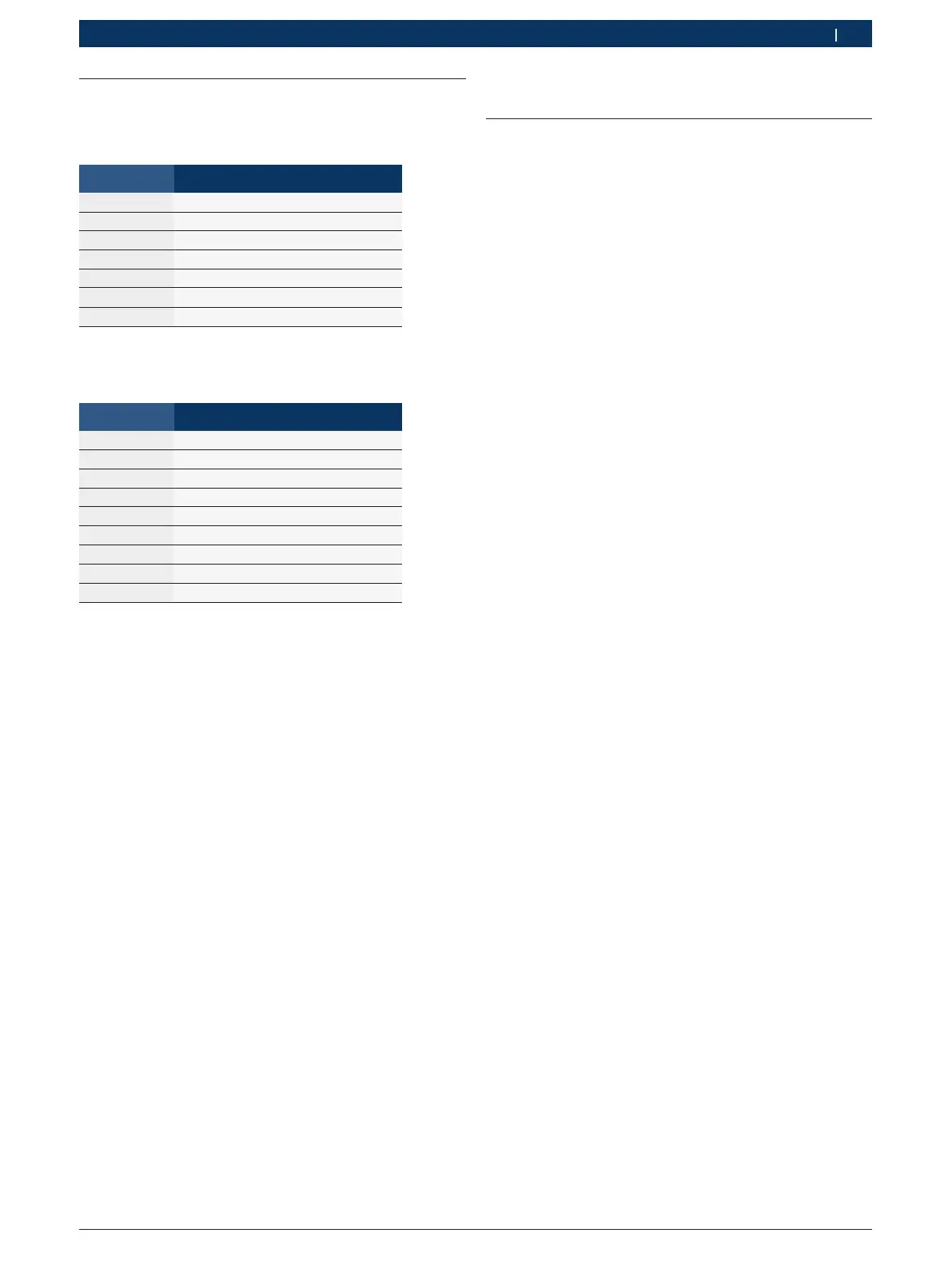

4.4.2 For RG4.0

Part number Part Description

RGB400230 Piston repair kit

RGB400240 Valve repair kit

RGB400250 Compressor repair kit

RGB400260 Shaft seal repair kit

RGB400270 Shaft replacement kit

RGB480270 Filter drier

RGB480280 Filter hose

RGB480290 Filter / hose kit

RGB480300 Inlet fitting with filter screen

5. Troubleshooting

5.1 Basic operational test

i By performing the basic operational test, you can

validate normal and correct operation of all features.

Refer to the table following this procedure if you

encounter any problems.

1. Ensure that there is no residual refrigerant left in the

RG8.0 / RG4.0. If there is residual refrigerant, refer

to chapter 3.2 for purging residual refrigerant.

2. With nothing connected to the RG8.0 / RG4.0 and

recovery / purge valve (black) in the RECOVER posi-

tion, open the inlet control valve (blue) and outlet

control valve (red) valves.

3. Start the RG8.0 / RG4.0 and close the inlet valve.

The RG8.0 / RG4.0 should shut-off due to Low

Pressure (LP) cut-out. Upon opening the inlet

valve, the RG8.0 / RG4.0 should restart.

4. Upon closing the outlet valve, the RG8.0 / RG4.0

should begin to pump up pressure on the High Side

(red) gauge.

When the pressure reaches approximately

38.5 bar, the RG8.0 / RG4.0 should shut off due

to High Pressure (HP) safety switch.

5. Slowly open the outlet valve and the RG8.0 / RG4.0

should restart when pressure drops below 28 bar.

Loading...

Loading...