D2 PHASER User Manual

DOC-M88-EXX141 V5 – 01.2015 17

write it down. In case of ‘Reference Determination’ press ‘Apply’ in order to accept these values

(fig. 55).

6. Check your reference determination with a new scan. Select a smaller range for 2

if desired (fig.

56). Press ‘reference determination’ again and check whether the result is satisfying as shown, for

example, in fig. 57 for reference determination. Normally, the reference determination is finished

after 2 iterations.

7. Insert and mount (properly) beam stop absorber module again (see section ‘Avoiding Collisions

with the D2 PHASER Goniometer’)

If anything was going wrong and the peaks are not at the position which you want, repeat the glass slit

scan, select ‘Reference And Offset Determination’, go to ‘Reference’ and enter the value you have

written down at step 4. above in the field ‘New Reference’, then press ‘Apply’. Then you have the

original status before reference determination.

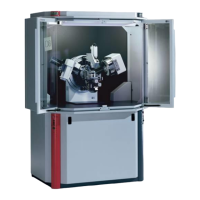

D2 PHASER user alignment with 0D-detector (Scintillation Counter and XFlash detector) and

standard sample holder

The primary and secondary Soller and slit holder system is preset and aligned at Bruker AXS factory

and fixed with a sealed screw (X-ray radiation safety!). The beam will pass the primary 0.1mm slit, the

glass slit and a secondary 0.1mm antiscatter slit or receiving slit, respectively, simultaneously at zero

position (fig. 45). The user must follow the steps of the alignment procedure described in the following:

1. Open the front door. Release the sample holder (fig. 51) and insert the glass slit module (fig. 48, fig.

49, fig. 50). Check whether the direct beam groove in the sample holder ring (fig. 51) is in beam

direction. Lift the sample holder back to the goniometer’s centre position (fig. 52). Close the front

door and move ‘phi’ to zero position (fig. 58). If necessary, initialize the rotation motor by clicking on

the ‘init’-button. If so, check again whether the direct beam groove is in direction of glass slit (fig. 53)

and direct beam respectively. Insert an absorber (Cu for Cu-radiation) into the holder position of the

Scintillation Counter (fig. 35). Close the door again and lock it by switching on HV.

2. Set the range of 2 from -1.0° to 1.0° (if the beam is not in this range then try a larger range), step

width to 0.01° and scan time to 0.1s with ‘locked coupled’ as scan type and ‘continuous psd fast

scan’ as scan mode (fig. 54). The screenshot fig. 55 shows an example of a scan where the glas

slit peak is shifted with respect to the zero of the 2

scale.

3. Move to ‘reference and offset determination’ and then ‘reference’. This window shows the

calculated peak position relative to the current scale. Press ‘apply’ in order to accept these values

(fig. 55).

4. Move to ‘Reference And Offset Determination’ and go to ‘Reference’. This window shows the

determined peak position relative to the current scale. Read the Value ‘Current Reference’ and

write it down. In case of ‘Reference Determination’ press ‘Apply’ in order to accept these values (fig.

55).

5. Check your reference determination with a new scan. Select a smaller range for 2

if desired (fig.

56). Press ‘reference determination’ again and check whether the result is satisfying as shown, for

example, in fig. 57. Normally, the reference determination is finished after 2 iterations.

6. Insert and mount (properly) beam stop absorber module again (see section ‘Avoiding Collisions

with the D2 PHASER Goniometer’)

Setting the parameters of the detector unit

Before you can start your work or even to align your diffractometer system, the parameters of the

detector electronics should be checked. In general these parameters are factory set and need not be

adjusted.

1. Detector high voltage (HV): For 1D-LYNXEYE, the signals and the amplification of the detector

depend on the HV. Best results may be expected with 120V. Other HV settings can destroy the

detector. For 0D-scintillation counters, the mutual dependence of HV and the Amplifier Gain are

optimized for any detector at factory.

Loading...

Loading...