User Manual D2 PHASER

DOC-M88-EXX141 V5 – 01.2015 22

X-ray safety precautions

Introduction

The D2 PHASER is approved as mobile and portable desktop instrument for operation within buildings

(no open-air operation!). This analytical instrument includes a powerful X-ray source. Shielding and

safety equipment guarantee that the emitted radiation does not exceed 1µSv/h H*(10) during normal

operation (anode materials with Z ≤ Z

Mo

, Z = atomic numer). Bruker AXS GmbH screens the emitted

X-ray radiation of each single D2 PHASER instrument prior to delivery under worst case conditions.

The D2 PHASER is in compliance with the requirements for X-ray systems which are certified as

complete protection instrument (“Vollschutzgerät”) according to the German X-ray standards called

“Röntgenverordnung” §2 Nr. 25 (cf. type approval D2-BfS 06/09 V RöV). The owner/user is explicitly

advised that the essential characteristics of the D2 PHASER which are specified in the type approval

may not be modified.

The enclosure of the D2 PHASER serves as radiation protection safety box. It must always be

ensured that the instrument corresponds to one of the specified configurations and that the safety

system is always working properly. Read section ‘Radiation protection and leakage levels’ before

switching on the instrument.

Danger! X-Ray Radiation

If it seems that the safety system or parts of the radiation protection and shielding

are not working correctly for any reason, you must switch off the system

immediately and contact your radiation protection officer and your local Bruker AXS

service organisation. Manipulations and modifications of the safety system and the

radiation protection and shielding parts are strictly forbidden!

Detailed description of the X-ray safety system

Radiation protection enclosure

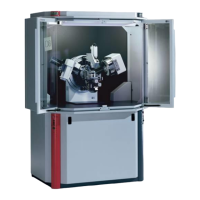

X-ray source, goniometer, sample holder, detector, and other components like electronics, computer

and cooling system are completely inside of the radiation protection enclosure. The sliding front door

of the enclosure is routinely opened to insert and change samples. The door is made of absorbing

steel with a TFT Display and a handle to open. The status (open/closed) of the front door is checked

by the safety circuit. The door is locked during X-ray operation. Details about the enclosure are

described in the section ‘radiation protection and leakage levels’.

Safety system

The safety system basically consists of two independent safety lines (SL1 and SL2). Both of them

have to be closed to enable HV for X-ray generation. A microcontroller monitors all components of the

safety circuits and permanently performs plausibility and functional checks. In case of any error which

affects the X-ray radiation safety, the two safety circuits will be interrupted and thus the X-ray radiation

will be switched off.

Safety line 1

SL1 uses the ‘enable I/O’ of the HV-Generator to enable or disable X-ray generation. The circuit is

only closed if all of the following components in SL1 have the expected settings: A pull wire in SL1

controls the correct position of the HV-cable. The pull wire can only be connected if the HV connector

is correctly attached to the X-ray tube. Users are able to break SL1 with a valid key (S101) to avoid

that unauthorized personnel enable HV-generation. A safety door lock mechanism (S104/K104) in SL1

guarantees that the front door is closed and locked while HV is active. Two enclosure switches with

forcibly guided contacts guarantee that the upper and lower part of the radiation safety enclosure fit

together and have correct and safe position. An external interlock in SL1 may be activated as an

option. It is not used in default configuration of the system. Any power supply fault like overvoltage,

Loading...

Loading...