User Manual D2 PHASER

DOC-M88-EXX141 V5 – 01.2015 24

microcontroller will perform the start-up checks and resume with normal operation mode if the error

condition is removed.

Radiation protection and leakage levels

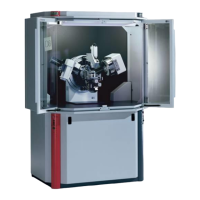

X-ray source, diffractometer, sample and other components are completely placed inside a radiation

safety housing with sliding front door (1.5mm steel plate) for user access. The lower part of the

housing is made of 2mm, the upper one of 1.5mm steel plates. A 2mm steel plate which carries the

goniometer separates the X-ray radiation section from the electronics section. X-rays can only be

generated if the lower and upper parts of the housing are put together correctly which is controlled by

two Schmersal safety switches. The sliding front door is controlled in the same way by 2 independent

safety circuits and a safety lock which avoids the opening of the door when X-ray is on. The

Schmersal door lock and safety module is protected with a cover. This cover is protected with one and

the safety switch actuator with two sealed safety screws in order to avoid illegal removal.

The X-ray source (tube) is enclosed by a shielding housing (without radiation safety shutter). X-rays

can only escape through one well defined window. The X-ray beam passes a primary optics housing

which limits the maximum opening angle significantly. Only a well defined beam hits the sample

position or inner housing wall. This primary optics housing is protected with one sealed safety screw in

order to avoid illegal removal. When the user wants to open the front door for sample access he has to

switch off the high voltage (HV) before. After HV-signal state ‘off’ was detected by the safety system,

the mechanical door lock is unlocked and the door is released.

The housing of the X-ray tube is attached to the primary angular arm with one sealed safety screw.

Furthermore the goniometer is attached to the basic carrier plate with one sealed safety screw. This

makes sure that the X-ray source cannot be removed from the angular arm or the goniometer from the

carrier plate, respectively, and deposited to an illegal place within the radiation section. The bottom of

the radiation section is strengthened by a 0.8mm steel plate. Two sealed safety screws protect the

plate against removal.

A safety system guarantees that X-rays cannot escape from inside of the radiation safe housing. Two

independent electrical safety circuits and alarm lamp monitoring circuits provide the interlock system.

The interlocks prevent X-ray generation if safety circuits are not intact. Warning lamps are lighting

when X-rays are on.

The radiation safe housing is checked to be a fully protected device when tested at maximum possible

power of 30kV, 300W with Mo radiation. The maximum dosage at a distance of 10 cm (4 inch) above

the surface of the outside of the radiation safe housing is less than 1Sv/h H*(10) for the configuration

with highest power (300W at 30 kV) in worst case settings (largest opening of primary optics and

strongly isotropic scattering sample or beam direction directly to the wall of the housing).

Radiation safety is always guaranteed independent what type of detector, sample or tube anode target

material (Mo, Cu, Cr, Co at 30kV @ 10mA) is used. Only Siemens tubes of types K FL $$ 2 K # ($$ =

type of anode material, # = wildcard character: C = ID-chip, void = no chip) may be used as X-ray

source for the D2 PHASER.

Resetting the D2 PHASER Safety System

If the Safety System detects any unsafe condition, it will go into error state, which is indicated in the

tools by a “red and white cross” icon. Generation of X-ray is prohibited in this state. Even after a restart

of the D2 PHASER, it will stay in this state to protect the operator. After checking and removing the

error condition, the Safety System needs to be reset to return to normal operation.

Choose the menu Tools / SafetyBoard. Get control over the safety board by clicking the “get control”

icon in the upper left corner (fig. 129). Then click the “reset” icon (fig. 123). A window for your

password will appear: enter the valid password and click the “send” button (fig. 124).

The Safety System will now start the reset procedure which takes approximately 10 seconds. During

this procedure several self tests are performed. If the error condition is no longer present, the Safety

System will return to normal operation, indicated by a “green checkmark” icon (fig. 125).

Loading...

Loading...