CS3000 User’s Guide

Calsense 79

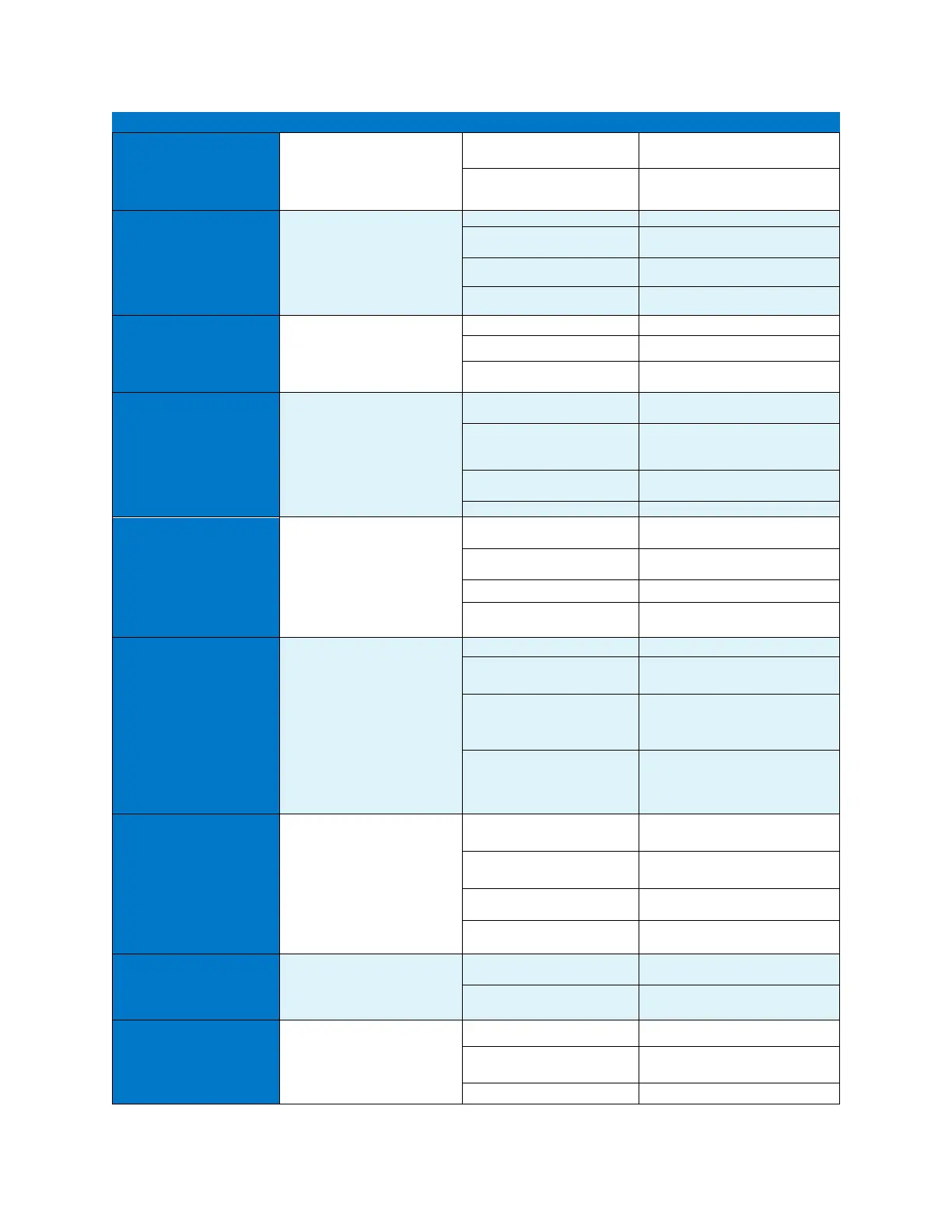

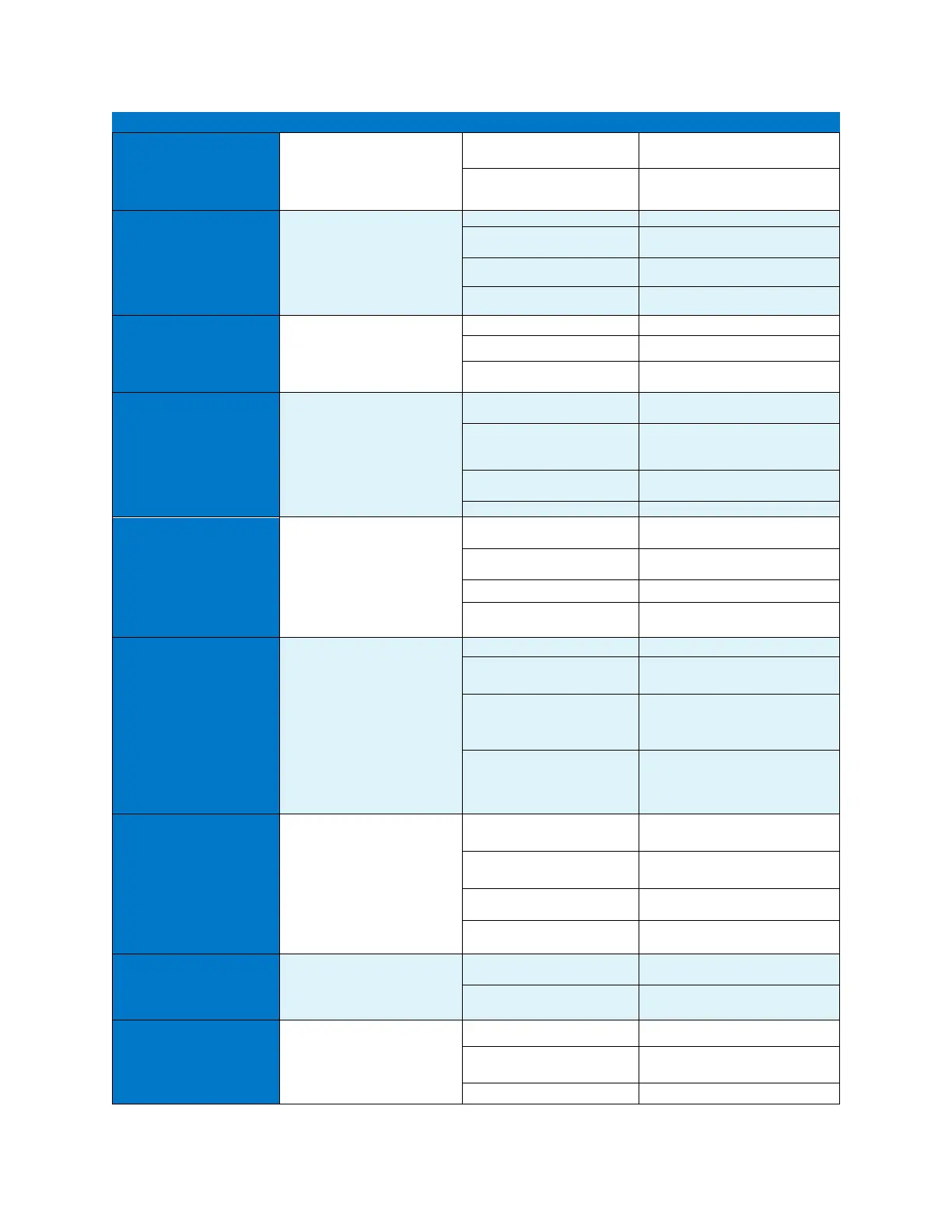

Problem Description Possible Causes Solution

Fuse Blown

The controller detected that the

fuse is blown.

Bad solenoid Replace the solenoid

Shorted 24 VAC output

Check if incoming power is 120

VACS

High Flow:

Station <num>: saw <num>

gpm, expected <num> gpm

An increased amount of water

flow was found.

Repair the broken head or lateral

Slow closing valve

Repair or replace slow closing valve,

or Enable delay between valves

Stuck valve Repair or replace stuck valve

Incorrect expected flow rate Adjust station’s expected flow rates

Low Flow:

Station <num>: saw <num>

gpm, expected <num> gpm

A decreased amount of water

flow was found.

Clogged head(s) Clear clogged head(s)

Flow control turned down Check flow control on valve

Incorrect expected flow

Adjust or reacquire the expected

flow rate

No Flow Detected by Flow

Meter:

Station <num>

No water flow found.

Valve did not open

Locate valve and check wire

connections and splices

Master valve did not open

Locate master valve and check wire

connections and splices

Problem with flow meter

Locate flow sensor and check wire

connections and splices

Mainline Break:

<name> while irrigating

A mainline break was detected

while irrigating.

Broken head

Locate the break and then fix or

replace part

To many valves are in use at

one time

Adjust number of valves in use

Broken laterals, fittings Locate and fix laterals and fittings

System capacity and MLB

settings need to be adjusted

Adjust data accordingly

Mainline Break:

<name> while not irrigating

A mainline break was detected

while not irrigating.

Leak in mainline Locate leak and fix the problem

Broken fitting or pipe Replace or patch fitting or pipe

Master Valve not closing on

normally closed system

Replace master valve

Employees manually operating

valves in field without telling

system.

Review system protocols

Mainline Break:

<name> while MV override

A mainline break was detected

while master valve was in

override.

Leak in mainline Locate leak and fix the problem

Broken fitting or pipe Replace or patch fitting or pipe

System capacity and MLB

settings need to be adjusted

Adjust data accordingly

To many valves are in use at

one time

Adjust number of valves in use

POC Decoder Voltage Too

Low:

Decoder S/N <num>

The voltage measured is too low

on identified decoder.

Damaged wires

Check wiring and replace or fix

wires

Bad splices Check splices

POC Decoder Not

Responding:

Decoder <Serial Number>

The decoder is not responding.

Power disruption Locate and fix the wire connection

Damaged wires

Check wiring and replace or fix

wires

Bad splice Check splices

Loading...

Loading...