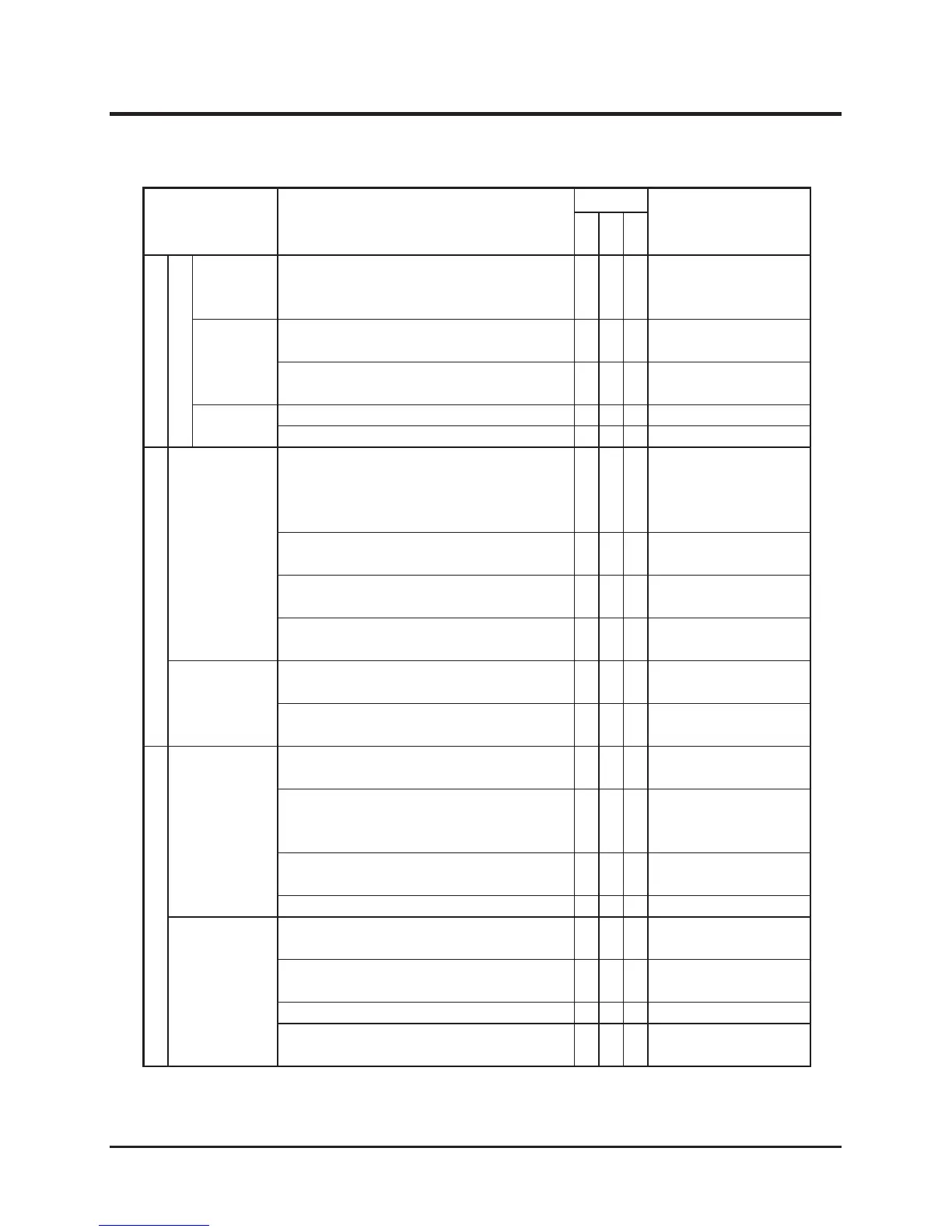

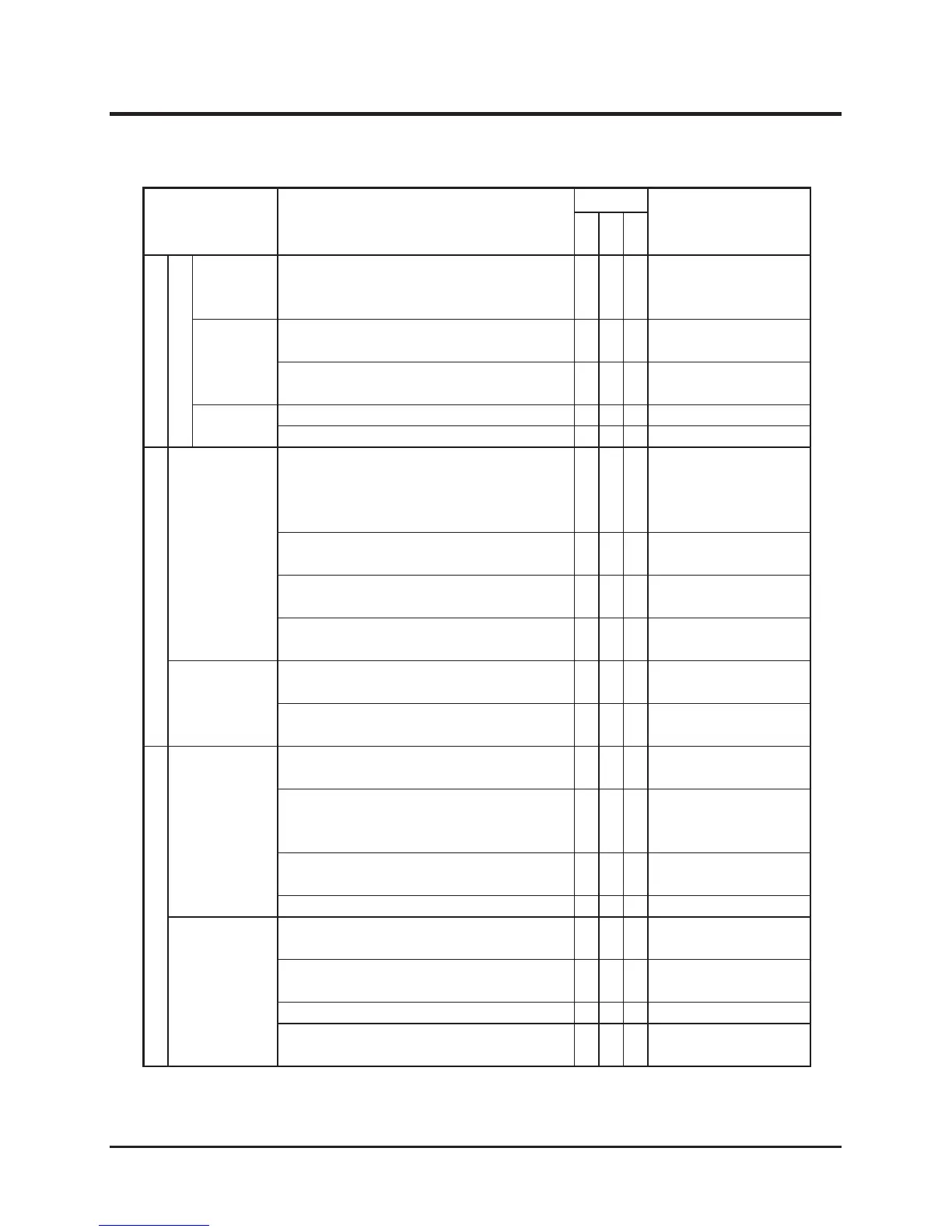

Item Description

Schedule

Note

PSI

Mon

Year

Engine

Electrical System

Charge

System

Charge system is working correctly.

√

Contact your CANYCOM

representative for

inspection.

Battery

Battery electrolyte level shall be correct.

√ √

Inspecting/Filling:

Page 58

Terminals shall be free of marked corrosion

and are tightly secured.

√ √

Wiring

Connections shall be securely connected.

√ √

Wiring shall be free of damages.

√ √

Drive Train

HST Pump

Drive the machine forward and backward,

turn left and right in both directions; machine

shall move normally and free of irregular

noise or overheating.

√ √ √

Hydraulic fluid shall be filled to a proper

level.

√ √

Inspecting/Changing:

Page 52

Hydraulic fluid shall be clean and free of dirt

or contamination.

√ √

Inspecting/Changing:

Page 52

There shall be no fluid leaks in or around

fluid tank.

√ √

Linkage

Rods, links, and wires in linkage shall be free

of deformation or damage.

√ √

Connections shall be free of looseness,

excessive play, or missing cotter pins.

√ √

Undercarriage

Wheels

Sprockets

Idlers

Shall be free of cracks, defromation, or

excessive wear.

√ √ √

There shall not be excessive play in axle.

Irregular noise or overheating shall not be

observed when traveling.

√ √ √

Mounting bolt or nut shall not be loose or

missing.

√ √ √

There shall be no oil leak in or around axle.

√ √

Tracks

There shall not be marked cut, deterioration,

or wear.

√ √ √

Track shall be properly tensioned; shall not

be too loose or too tight.

√ √ √

Adjusting: Page 50

Track core shall not be missing or damaged.

√ √ √

Tension bolt shall be free of deformation or

corrosion.

√ √ √

Loading...

Loading...