25

ENG

ir33 universale +030220801 - rel. 2.1 - 21.06.2011

4. COMMISSIONING

4.1 Con guration

The con guration parameters should be set when commissioning the

controller, and involve:

• serial address for the network connection;

• enabling the keypad, buzzer and the remote control (accessory);

• setting a delay for starting control after the device is powered up (delay

at start-up);

• gradual increase or reduction in the set point (soft start).

4.1.1 Serial address (parameter c32)

c32 assigns the controller an address for the serial connection to a

supervisory and/or telemaintenance system.

Par. Description Def Min Max UoM

c32 Serial connection address 1 0 207 -

Tab. 4.a

4.1.2 Disable keypad/remote control (parameter c50)

Some functions relating to the use of the keypad can be disabled, for

example, the setting of the parameters and the set point if the controller

is exposed to the public.

Par. Description Def Min Max UoM

c50 Disable keypad and remote control 1 0 2 -

Tab. 4.b

Below is a summary of the modes that can be disabled:

Par c50 Edit P

parameters

Change

set point

Settings from

remote control

0 NO NO YES

1 YES YES YES

2NO NO NO

Tab. 4.c

With the “change set point” and “edit P parameters” functions disabled,

the set point and the type P parameters cannot be changed, however

the values can be displayed. The type c parameters, on the other hand,

being protected by password, can be set on from keypad, following the

standard procedure. With the remote control disabled, the values of the

parameters can be displayed but not set. See the paragraph on using the

remote control.

If c50 is set =2 from the remote control, this is instantly disabled. To

re-enable the remote control, set c50=0 or c50=1 on the keypad.

4.1.3 Show standard display/disable buzzer

(parameters c52,c53)

Par. Description Def Min Max UoM

c52

Display

0=Probe 1

1=Probe 2

2=Digital input 1

3=Digital input 2

4= Set point 1

5= Set point 2

6= Probe 1 / Probe 2 alternating

003 -

c53

Buzzer

0=Enabled

1=Disabled

001 -

Tab. 4.d

4.1.4 Delay at start-up (parameter c56)

Used to delay the start of control when the device is powered up. This is useful in the

event of power failures, so that the controllers (in the network) don’t all start at the

same time, avoiding potential problems of electrical overload.

Par. Description Def Min Max UoM

c56 Delay at start-up 0 0 255 s

Tab. 4.e

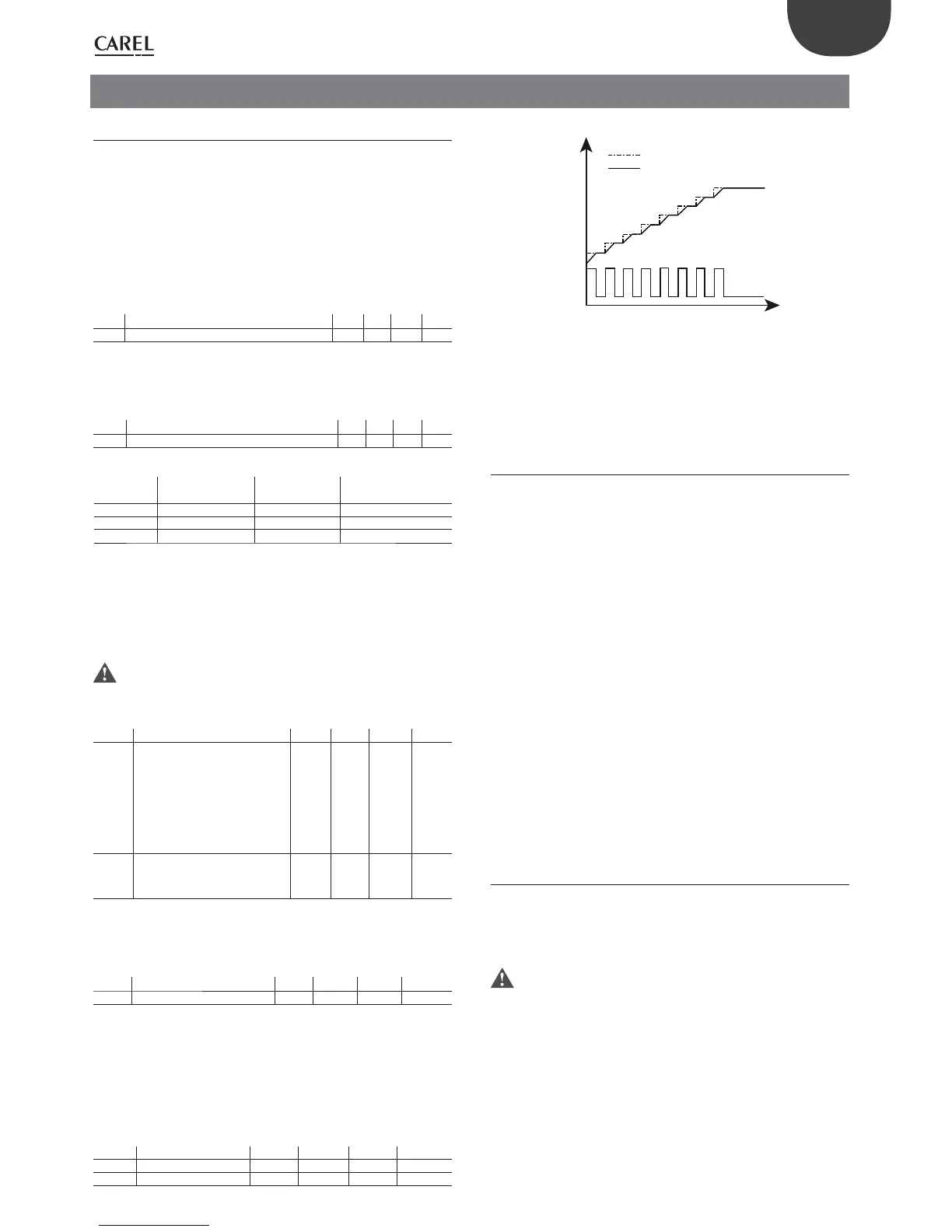

4.1.5 Soft start (parameter c57, d57)

This function is used to gradually increase or decrease the set point

according to the value of the parameter. The function is useful if the

controller is used in cold rooms or seasoning rooms, or in similar

situations when starting at full load may not be compatible with the

required process. Soft start, if active, is used on power-up or within an

operating cycle. The unit of measure is expressed in minutes / °C.

Parameter d57 acts on circuit 2 if independent operation is active.

Par. Description Def Min Max UoM

c57 Soft start 0 0 99 min/°C

d57 Soft start circuit 2 0 0 99

min/°C

Tab. 4.f

°C

set point

process value

output status

Fig. 4.a

Example: when c57=5, assuming the set point is 30°C and the di erential 2

°C, and that the ambient temperature is 20°C; on power-up the virtual set

point will be the same as the temperature measured, and will remain at this

value for 5 minutes. After 5 minutes, the virtual set point will be 21 degrees,

no outputs will be activated, while after another 5 minutes the virtual set

point will be 22°C, thus entering the control band (as the di erential is 2°C)

and heating will start. Once the temperature reaches the virtual set point,

the function stops and the process continues.

4.2 Preparing for operation

Once having completed the installation, con guration and programming

operations, before starting the controller check that:

• The wiring is performed correctly;

• The programming logic is suitable for controlling the unit and the

system being managed: Starting from revision FW 2.0 two PID control

cycles can be set on two independent circuits;

• If the controller is tted with RTC (clock), set the current time and the

on and o times;

• Set the standard display;

• Set the “probe type” parameter based on the probe available and the

type of control (NTC, NTC-HT, PTC, PT1000, J/K thermocouple, voltage/

current input);

• Set the type of control: ON/OFF (proportional) or proportional, integral,

derivative (PID);

• If used as a thermostat, set the unit of measure for the probes (°C or °F),

see paragraph 5.1;

• Any operating cycles are programmed correctly;

• The protection functions (delay at start-up, rotation, minimum on and

o times for the outputs) are active;

• The remote control enabling code is set, if a series of controllers are

installed in the same system;

• If the CONV0/10A0 module is connected, the cycle time is set to the

minimum (c12=0.2 s);

• The special mode is set in the correct sequence, i.e. rst parameter c0 is

set, and then parameter c33 (see the chapter on Functions).

4.3 Switching the controller On/O

The device can be switched ON/OFF from several sources: supervisor,

digital input (parameters c29, c30), parameter (Pon) and remote control.

The digital input has highest priority in switching ON/OFF. Staring

from revision 2.0 an output can be selected for ON-OFF status (see

“dependence”).

If more than one digital input is selected as On/O , the ON status will

be activated when all the digital inputs are closed. If just one contact

is open, the unit is switched OFF.

In OFF status set from digital input, the outputs and switching ON/OFF

from remote control or the supervisor are disabled, while the following

functions are enabled:

• editing and display of the frequent and con guration parameters, and

the set point;

• selection of the probe to be displayed;

• probe 1 error (E01), probe 2 error (E02), clock alarm (E06), EEPROM

alarm (E07 and E08);

• When switching ON and OFF the control output protection times are

taken into consideration;

Loading...

Loading...