39

ENG

ir33 universale +030220801 - rel. 2.1 - 21.06.2011

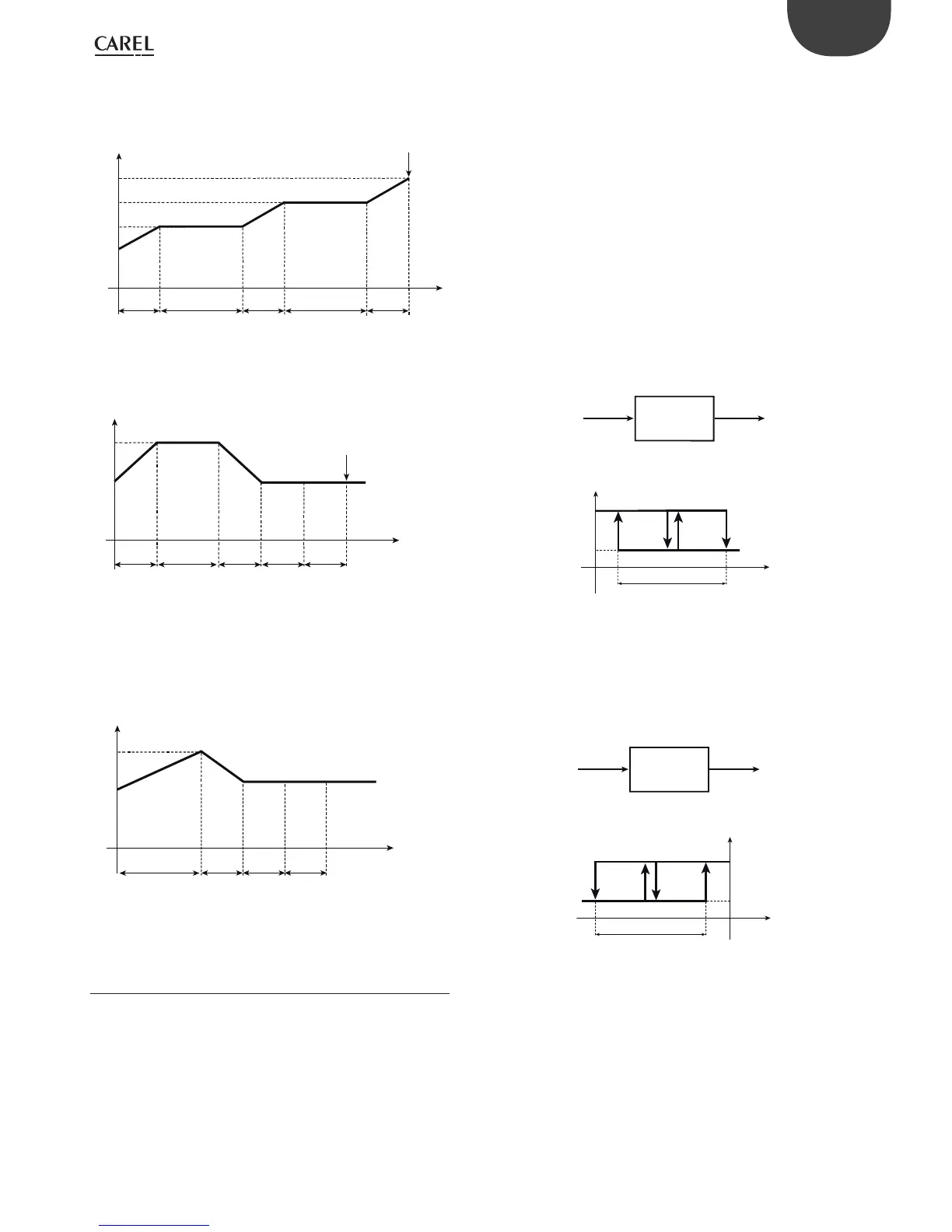

Example 2: Heating cycle with intermediate pauses

At the end of Step5, the operating cycle ends automatically and control

resumes based on Set1.

automatically exit the operating cycle

t

T

STEP1

P71=30’

P72=SetA

STEP2

P73=40’

P74=SetA

STEP3

P75=30’

P76=SetB

40’

SetA

SetB

30’ 30’

40’

STEP4

P77=40’

P78=SetB

30’

STEP5

P79=30’

P80=SetC

SetC

Set1

Fig. 6.b

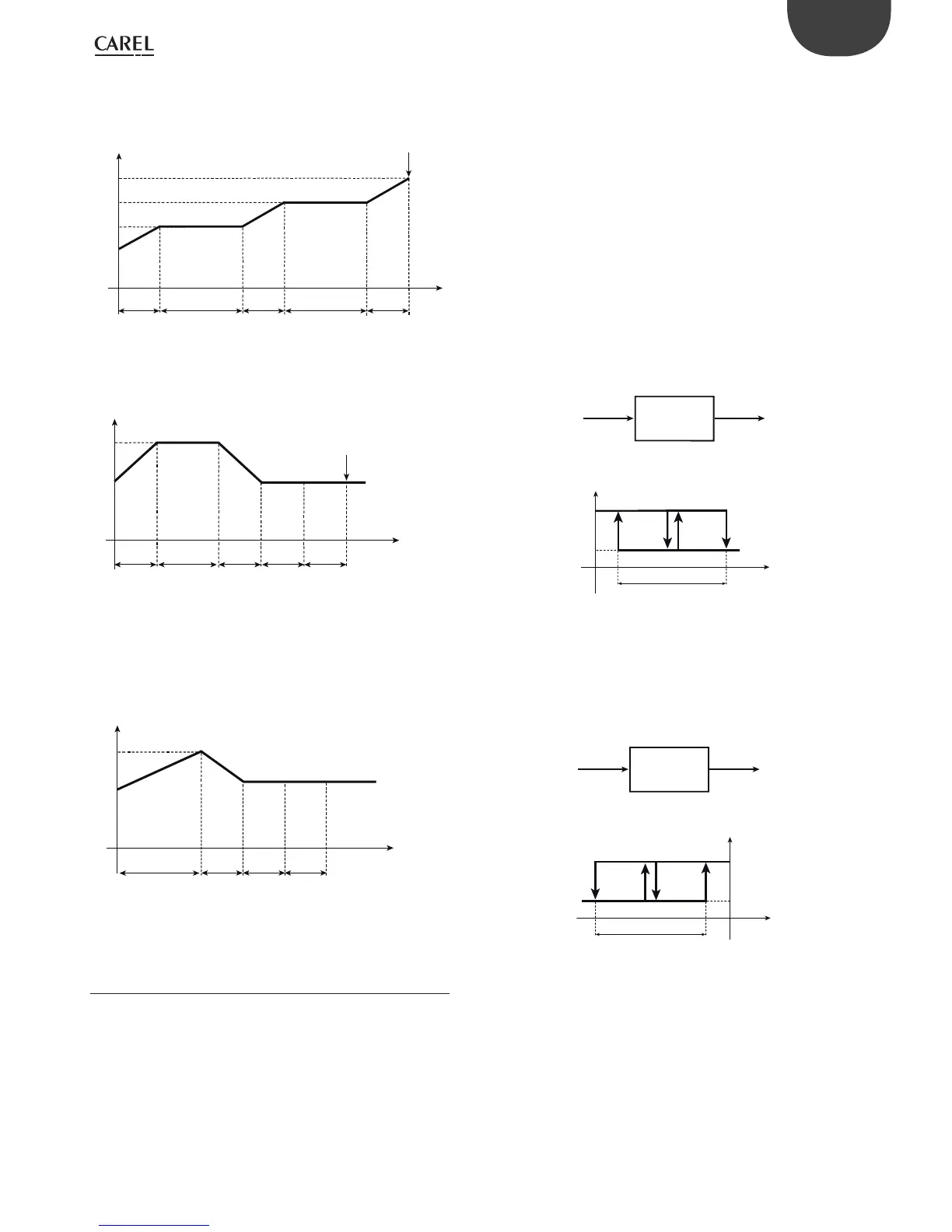

Example 3: Low pasteurisation cycle

At the end of Step5, the operating cycle ends automatically and control

resumes based on Set1.

t

T

STEP1

P71=30’

P72=Set2

STEP2

P73=45’

P74=Set2

STEP3

P75=30’

P76=Set1

STEP4

P77=1’

P78=Set1

45’

Set1

SetA

30’ 30’ 1’

STEP5

P79=1’

P80=Set1

1’

Fig. 6.c

Example 4: High pasteurisation cycle

In this example, having set the time for the last step to “0”, the operating

cycle does not end until the operator intervenes, and temperature

control continues in nitely. As the temperature for in nite temperature

control is equal to the temperature set for Set1, the system will behave as

if it were in normal control, however the display will show CL5 to indicate

that the operating cycle is still in progress.

t

T

STEP1

P71=60’

P72=SetA

STEP2

P73=30’

P74=Set1

STEP3

P75=1’

P76=Set1

Set1

SetA

60’

30’ 1’

STEP4

P77=1’

P78=Set1

1’

STEP5

P79=0

P80=Set1

Fig. 6.d

Key

T= temperature

t = time

6.5 Operation with probe 2

Installing probe 2 allows various types of operation to be enabled,

selected using parameter c19.

6.5.1 Di erential operation (parameter c19=1)

The second probe (B2) must be installed. Control is performed by

comparing the set point St1 against the di erence between the two

probes (B1-B2). In practice, the controller acts so that the di erence B1-B2

is equal to St1. As mentioned, the management of the second probe is

only available in modes c0=1 & 2.

“Direct” operation (c0=1) is suitable for applications in which the controller

needs to stop the di erence B1-B2 from increasing.

“Reverse” operation (c0=2), on the other hand, stops the di erence B1-B2

from decreasing. Below are some examples of applications.

Example 1:

A refrigeration unit with 2 compressors must lower the temperature of

the water by 5°C.

Introduction: having selected a controller with 2 outputs to manage the

2 compressors, the rst problem to be faced relates to the positioning

of probes B1 and B2. Remember that any temperature alarms can only

refer to the value read by probe B1. The example indicates the inlet

temperature as T1 and the outlet temperature as T2.

Solution 1a: install B1 on the water inlet if it is more important to control

the inlet temperature T1; that will allow alarm signals, where necessary

delayed, relating to a “High” inlet temperature T1. For example, when

B1=T1 the set point corresponds to “B1-B2”, i.e. “T1-T2”, and must be equal

to +5°C (St1=5). The operating mode will be “reverse” (c0=2), given that

the controller activates the outputs as the value of “T1-T2” decreases,

and tends towards 0. Choosing a di erential equal to 2°C (P1=2), a high

temperature threshold equal to 40°C (P26=40) and a delay of 30 minutes

(P28=30), the operation will be as described in the following gure.

B1 (T1)B2 (T2)

CHILLER

St1=5

OUT2 OUT1

Mod. W

B1-B2

P1

ON

OFF

Fig. 6.e

Solution 1b: if on the other hand priority is attributed to T2 (e.g. “Low

temperature” threshold 6°C with a one minute delay), the main probe,

B1, must be set as the outlet temperature. With these new conditions,

the set point St1, equal to “B1-B2”, i.e. ‘T2-T1’, must now be set to -5°C.

The operating mode will be “direct” (c0=1), given that the controller must

activate the outputs as the value of ‘T2-T1’ increases, and from -5 tends

towards 0. P25=6 and P28=1(min) activate the “Low temperature” alarm,

as shown in the new control logic diagram:

B2 (T1)B1 (T2)

CHILLER

St1=-5

OUT1 OUT2

Mod. W

B1-B2

P1

ON

OFF

Fig. 6.f

Example 1 (continued)

Example 1 can be resolved using “special” operation (c33=1). Starting

from solution 1b (T2 must be 5°C less than T1). The main probe is located

at the outlet (T2 =B1).

These requirements also need to be satis ed:

• the outlet temperature T2 must remain above 8°C;

• if T2 remains below 6°C for more than one minute, a “Low temperature”

alarm must be signalled.

Solution: use a controller with 4 outputs (IR33Z****); two outputs are

used for control (OUT3 and OUT4), and one for the remote alarm signal

(OUT1). OUT2 will be used to deactivate outputs OUT3 and OUT4 when

T2< 8°C. To do this, simply connect OUT2 in series with OUT3 and OUT4,

then make OUT2 active only when B1 (T2) is greater than 8°C.

Loading...

Loading...