37

ENG

ir33 universale +030220801 - rel. 2.1 - 21.06.2011

6. CONTROL

ON/OFF and PID control

The controller can operate with two types of control:

• ON/OFF (proportional), in which the actuator either operates at full

power or is o . This is a simple control mode that in certain cases can

achieve satisfying results;

• PID, useful for systems in which the response of the controlled value

compared to the changeable value does allow to eliminate the error

in steady operation and improve the regulation. The changeable value

becomes an analogue value that continuously varies between 0 and 100%.

In PID control, the proportional band coincides with the di erential

(parameters P1/P2).

6.1 Type of control (parameter c32)

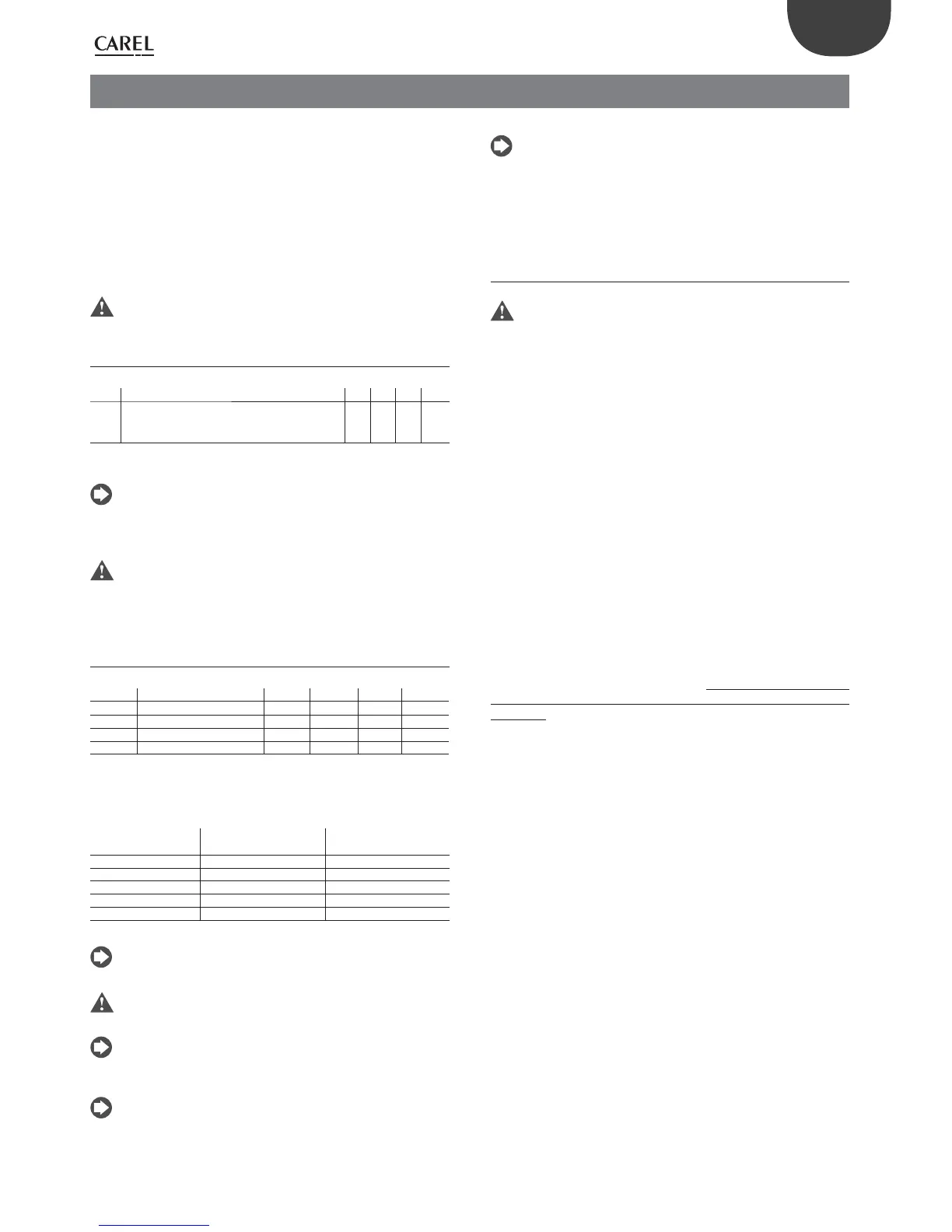

Par. Description Def Min Max UM

c5 Type control

0=ON/OFF(proportional)

1=Proportional+Integral+Derivative (PID)

001-

Tab. 6.a

This parameter is used to set the most suitable type of control for the

process in question.

With PID, e ective control means the controlled value coincides with

the set point or falls within the dead zone; in these conditions, a

series of outputs may be active even if not envisaged in the original

control diagram. This is the most evident e ect of the integral factor.

PID control, before being applied, requires proportional control only

without swings and with good stability in the di erentials: only

when there is stable P control can PID guarantee maximum e ectiveness;

6.2 ti_PID, td_PID (parameters c62,c63,

d62,d63)

These are the PID parameters to be set for the application

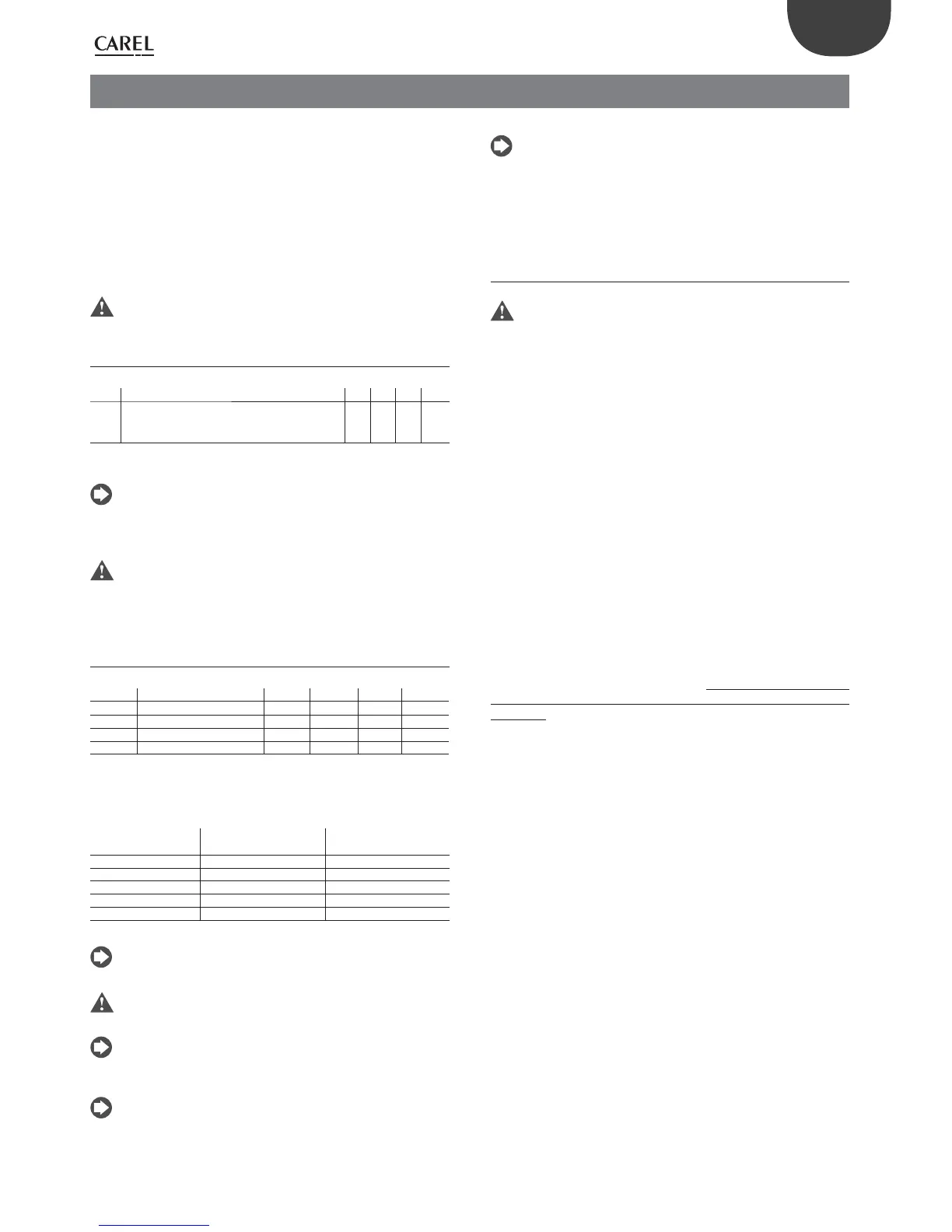

Par. Description Def Min Max UoM

c62 ti_PID1 600 0 999 s

c63 td_PID1 0 0 999 s

d62 ti_PID2 600 0 999 s

d63 td_PID2 0 0 999 s

Tab. 6.b

The table below shows the probe used by PID1 and PID2 based on the

setting of c19.

c19 PID1

(dependence=1)

PID2

(dependence = 2)

1 B1-B2 B1

7 B1 (circuit 1) B2 (circuit 2)

8 max(B1, B2) B1

9 min(B1, B2) B1

0, 2, 3, 4, 5, 6, 10, 11 B1 B1

Tab. 6.c

For the explanation of operation of control based on the setting of

c19, see par. 6.5.

To eliminate the e ect of the integral and derivative factors, set the

respective parameters ti and td=0

Setting td=0 and ti ≠ 0 achieves P+I operation, widely used for

controlling environments in which the temperature does not have

considerable variations.

To eliminate the error in steady operation, PI control can be

implemented, as the integral factor reduces the average value of the

error. Nonetheless, a high impact of this factor (remember that it

contributes in an inversely proportional way to the time ‘ti’) may increase

temperature swings, overshoots and the time taken for the controlled

variable to increase and decrease, bringing instability.

To resolve such overshoots due to the use of the integral time, the

derivative factor can be introduced, which acts as a damper to the

swings. Nonetheless, needlessly increasing the derivative factor

(increasing the time ‘td’) increases the time taken for the controlled

variable to increase and decrease and can also cause system instability.

The derivative factor however has no a ect whatsoever on the error in

steady operation.

6.3 Auto-Tuning (parameter c64)

The Auto-Tuning function is incompatible with independent

operation (c19=7).

The controller leaves the factory with default settings of the PID

parameters; these allow standard PID control, but are not optimised for

the system that IR33 controls. Consequently, the Auto-Tuning procedure

can be used to ne-tune the 3 parameters involved, so as to ensure

control that is optimised for the system where it is installed: di erent

systems, with di erent dynamics, will generate parameters that di er

greatly.

Auto-Tuning includes two operating procedures:

• Tuning the controller when commissioning the system.

• Fine-tuning the controller with parameters that have already

been tuned, during normal operation.

In both modes, the control rst needs to be programmed setting the

following parameters:

c0 =1 or 2, that is, “direct” or “reverse” control;

c5 =1, that is, PID control enabled;

c64 =1, that is, Auto-Tuning enabled;

St1= working set point.

Tuning the controller when commissioning the system.

This procedure is performed when commissioning the system, and

involves an initial tuning of the PID control parameters to analyse

the dynamics of the overall installation; the information acquired is

indispensable for both this procedure and any further tuning operations

performed.

During commissioning, the system is in a stationary state, that is, it is

not powered and is in thermal balance at room temperature; this state

must be maintained when programming the controller before starting

the Auto-Tuning procedure. The controller must be programmed by

setting the parameters speci ed previously, making sure to avoid starting

to control the loads and thus altering the state of the system (that is,

increasing or decreasing the temperature). This can be achieved by not

connecting the control outputs to the loads or keeping the loads o (not

powered). Once programmed, the controller must be switched o , if

necessary the connections of the outputs to the loads must be restored

and nally power connected to the entire system: controller and unit.

The controller will then start the Auto-Tuning procedure, identi ed by the

TUNING icon ashing on the display, performing a preliminary check on

the starting conditions, and assessing their suitability, that is, for a system

in “direct” mode the starting temperature measured by the control probe

must be:

-higher than the set point;

-more than 5°C from the set point;

for a system in “reverse” mode, the starting temperature measured by the

control probe must be:

-lower than the set point;

-more than 5°C from the set point.

If the starting conditions are not suitable, the procedure will be not

be started and the controller will show the corresponding alarm “E14”;

the controller will remain in this status without perform any operation,

awaiting a reset or until switched o and on again. The procedure can

be repeated to check whether the starting conditions have changed and

Auto-Tuning can start. If on the other hand the starting conditions are

suitable, the controller will start a series of operations that modify the

Loading...

Loading...