8.3 - Flow rate detection

Standard unit

All units are equipped as standard with a factory-set ow switch.

It cannot be adjusted on site.

The energy transfer uid pump must be servo-controlled by the

unit: dedicated terminals are provided for installing the energy

transfer uid pump servo control (auxiliary operation switch of the

pump to be wired on site).

Unit with hydraulic module option

The “ow rate detection” functionality is handled by the option via

the pressure sensors.

8.4 - Cavitation protection (with hydraulic

module option)

To ensure the durability of pumps tted on the built-in hydraulic

modules, the control algorithm of units in the range includes

protection against cavitation.

It is therefore necessary to ensure a minimum pressure of 60 kPa

(0.6 bar) at the pump inlet both when shut down and during

operation.

A pressure below 60 kPa will prevent unit start-up, or will cause

an alarm and shut-down.

A pressure below 100 kPa will trigger an alert on the user interface.

To obtain an adequate pressure, it is recommended:

- To pressurise the hydraulic circuit between 100 kPa (1 bar)

and 400 kPa (4 bar) maximum at the pump inlet;

- To clean the hydraulic circuit during water lling or after any

modications are made;

- To regularly clean the screen lter.

8.5 - Auxiliary electrical heaters

Specic data 30RQ/30RQP

To compensate for the decrease in the heat pump's output at low

ambient temperatures, which changes signicantly as shown in

the graph below, it is possible to install backup electric heaters on

the unit's water outlet.

These heaters (not supplied) can be controlled via option 156.

Four outputs are available to control the switches (not supplied)

on the heaters, allowing gradual compensation of the heat pump

output reduction.

These outputs can be congured to obtain two, three or four stages

(as required), the last stage only being activated in the event of a

default shut-down of the heat pump (safety).

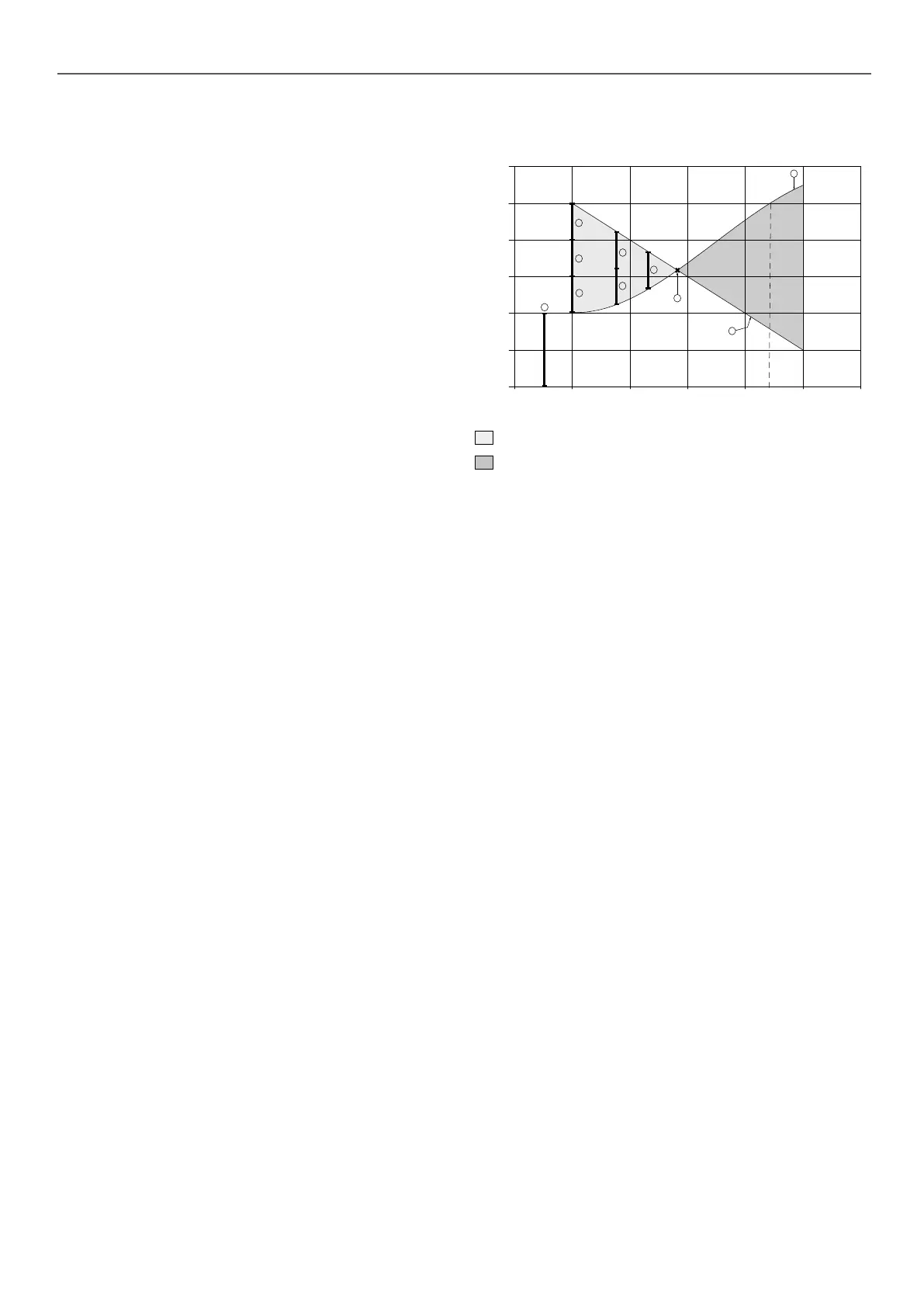

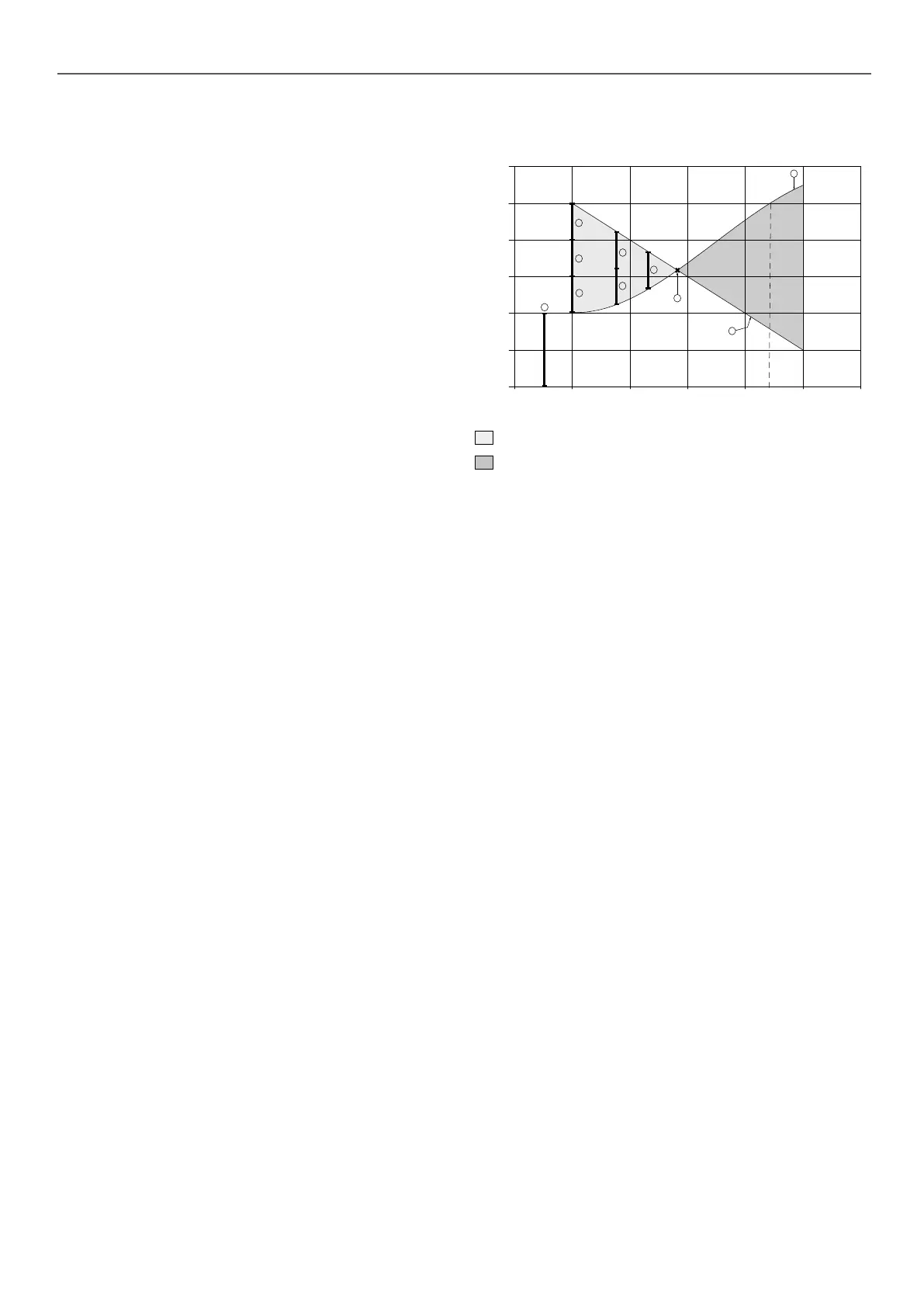

Example of additional heaters

In the graph, the power of the four heaters equals the capacity of

the heat pump at an outdoor air temperature of 7 °C.

1

A

2

3

4

B

120

100

80

60

40

20

0

-15-10 -5 05 10 15

1

1

2

C

Outdoor air (°C)

% Customer power

Operating range for which the heat pump output is less than the building

heat load

Operating range for which the heat pump output is greater than the building

heat load

1 Stage 1

2 Stage 2

3 Stage 3

4 Stage 4 (safety)

A

Variation of the heat pump output with air temperature

B Building heat load

C Equilibrium point between the heat pump output and the building heat load

8.6 - Frost protection

IMPORTANT: Damage caused by frost is not covered by the

warranty.

The plate heat exchanger, the pipes and the hydraulic module

pump(s) can be damaged by frost. The components of the unit

(heat exchanger, pipes, hydraulic module) are protected by

following the recommendations below. Protection of the remainder

of the system is the responsibility of the installer.

The plate heat exchanger and all the components of the hydraulic

circuit can be protected against freezing by draining the entire

machine completely, checking that there are no retention points.

If this is not possible, the plate heat exchanger and all the

components of the water circuit can be protected against freezing:

- Down to -20 °C by heaters and heat trace cables (tted as

an option on the exchanger and internal pipe system) supplied

automatically (for units without the hydraulic module)

- Down to -20 °C by heaters and heat trace cables (tted as

an option on the water type heat exchanger and internal pipe

system) supplied automatically and pump on/o activation

(for units with hydraulic module)

Never power o the heaters for the water type heat exchanger

and the hydraulic circuit or pump, as they will no longer be

providing frost protection.

To ensure they continue to receive power, the main disconnect

switch for the unit or the customer's circuit and the auxiliary circuit

breaker for the heaters must be left closed (see the wiring diagram

for the location of these components).

To protect units with a hydraulic module from freezing, water must

be circulated in the water circuit by the pump, which is activated

at regular intervals.

8 - WATER CONNECTIONS

37

Loading...

Loading...