6-MAINTENANCE

Torquespecications

Servicespecications

Check:Every250hours(aftertherst50hoursduringtherun-inperiod)

Attheendofeachworkingday,checkallmountingnutsandscrewsfortightnessandtightenifnecessary.Makesure

nohardwareitemsaremissing.Replacethem,ifnecessary.

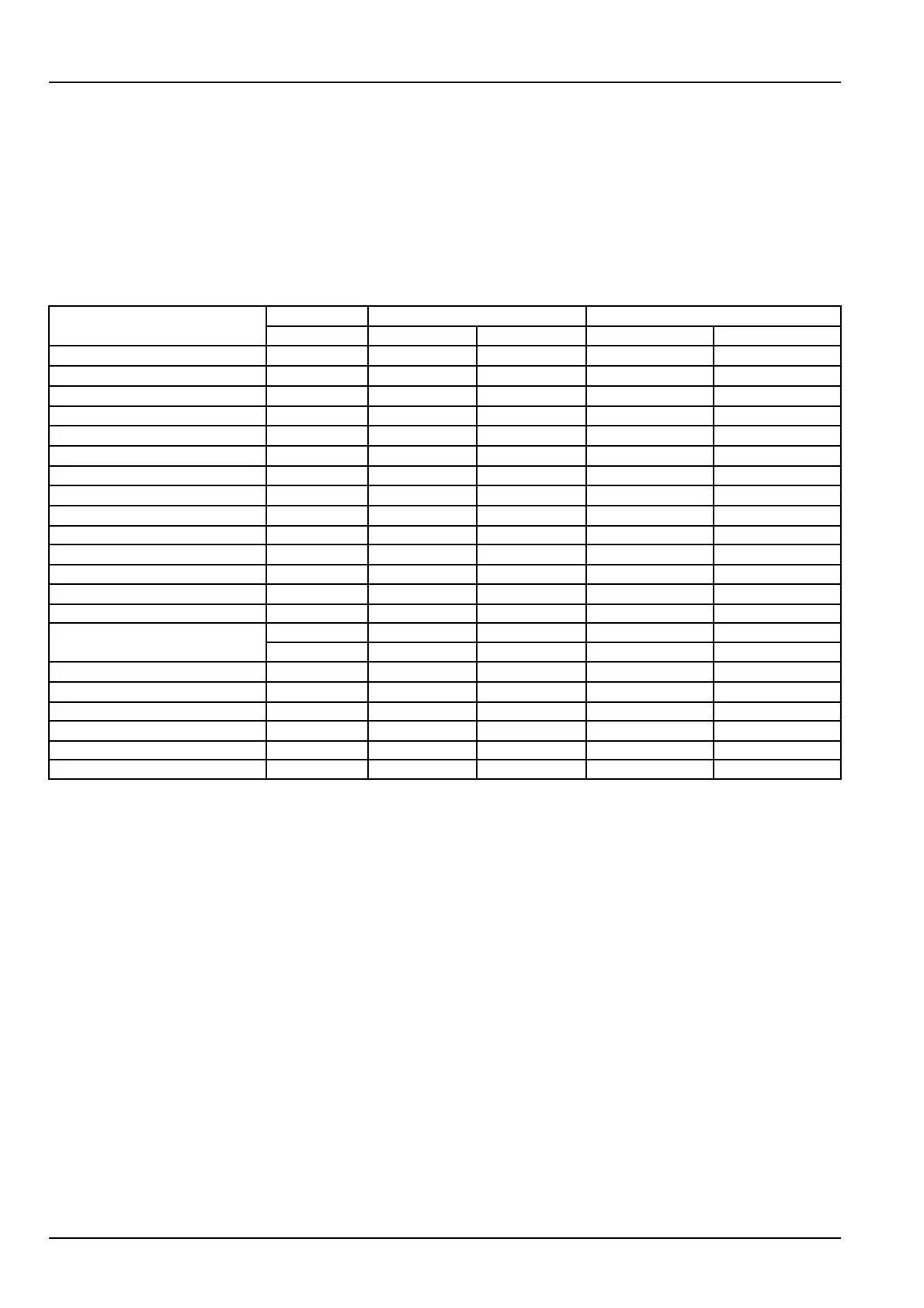

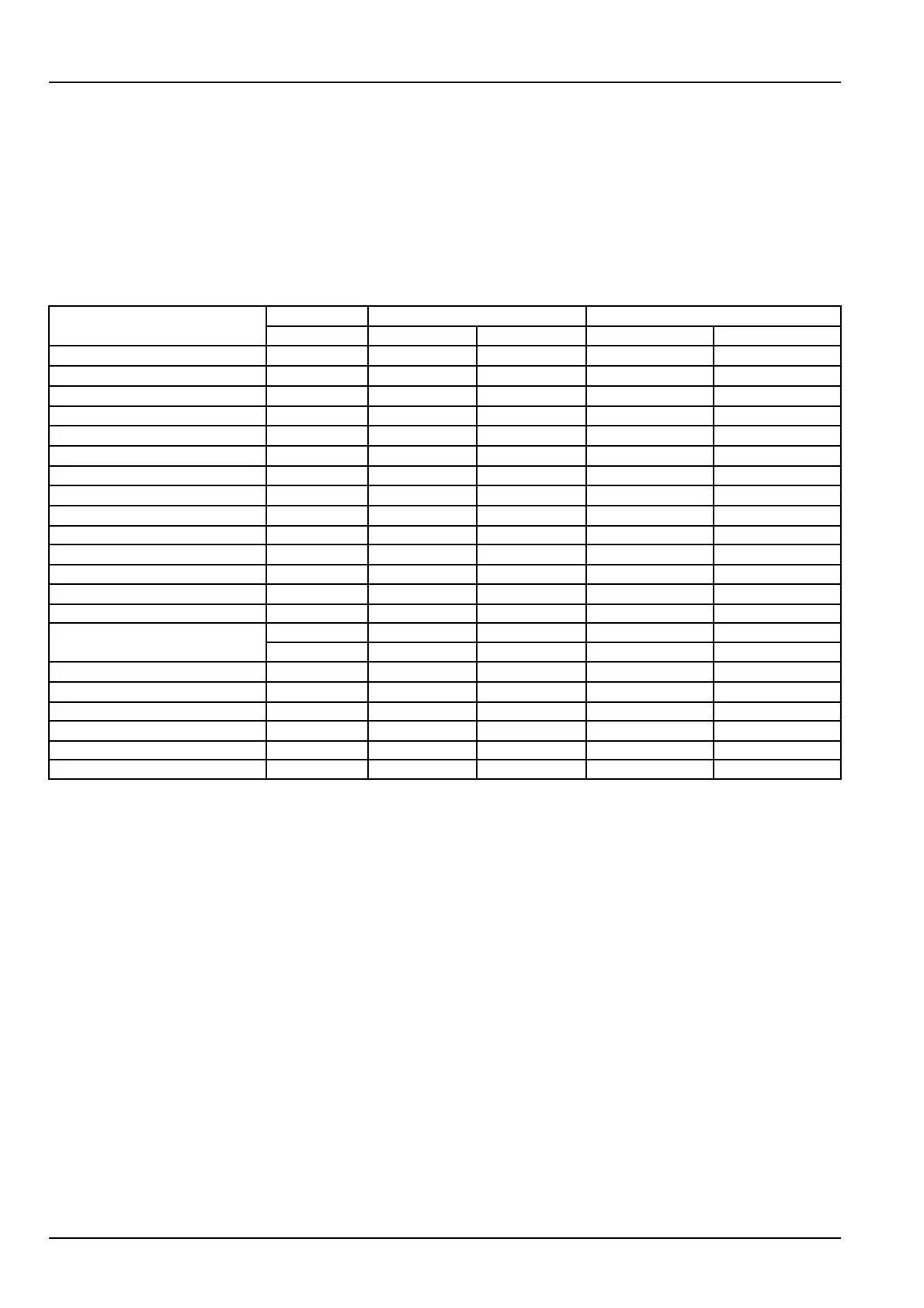

Torquespecicationspercomponent

Screw

Wrench

Torquesetting

Component

(Ø)

mm

inNm

lbft

Travelreductiongear(*)

M16240.9267–312197–230

Drivesprocket(*)

M16240.9267–312197–230

Idlerwheel(*)

M16240.9267–312197–230

Upperroller(*)

M20301.2521–608384–448

Lowerroller(*)

M18271.1371–432274–319

Chainguide(*)

M18271.1400–462295–341

Trackpad600mm(23.6in)

M20301.2250–350184–258

Trackpad800mm(31.5in)

M20301.2755–853557–629

Counterweight

M335021862–20581373–1517

TurntableM20301.2468–545345–402

Swingreductiongear(*)

M20301.2540–629398–464

Engine(*)

M10/M1617/240.7/0.964–74/206-24747–54/152-182

Enginemounts(*)

M16240.9265–314195–231

RadiatorM16240.9147–177108–130

M10170.764–7347–54

Hydraulicpump(*)

M20

hexagonalhexagonal

367–496271–366

Hydraulicreservoir(*)

M16240.9232–276171–204

Fueltank(*)

M16240.9232–276171–204

Controlvalve

M16240.9267–312197–230

Hydraulicswivel(*)

M12190.7109–12780–94

Cab

M16240.9149–173110–128

BatteriesM10170.720–2915–21

NOTE:UseLoctite262,ortheequivalent,onscrewsmarked(*).

6-74

Loading...

Loading...