9

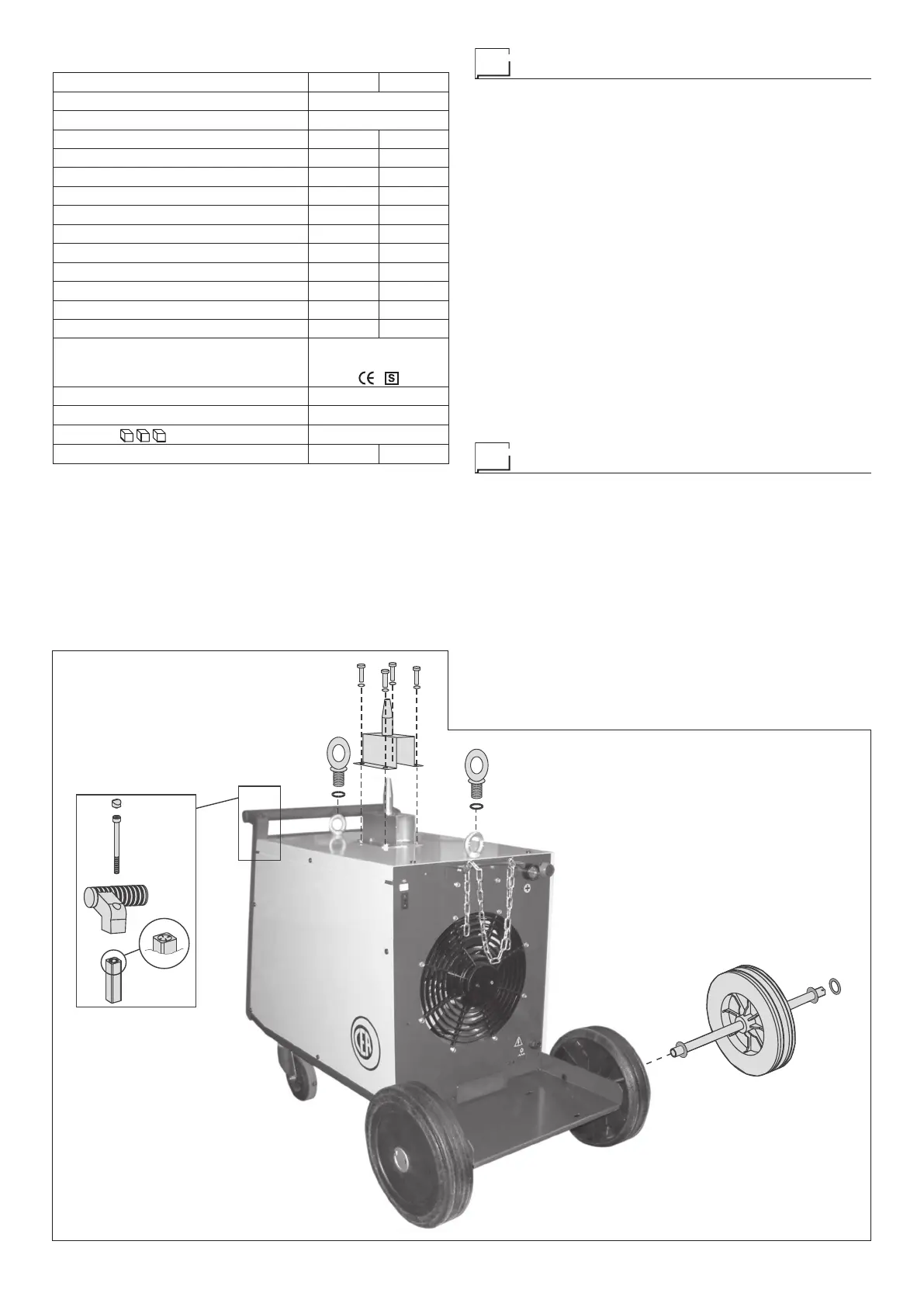

Assembling the welding machine

The standard composition of this welding installation consists

of:

• MAXI 405 or 505 generator.

• Earthing cable 4 m long (optional).

Accessories also include front and back wheels for moving

the welder, a chain for fastening the gas cylinder to the cylin-

der trolley easily, a handle especially for moving the machine

around manually, two eyebolts for lifting the machine off the

ground, a pivot to make sure the wire feeder is in the right po-

sition above the machine. Perform the following operations be-

fore using the machine:

• Open the case (box carton) and take out all the accessories

at the back of the welder.

•

Mount the back wheels following the description given in

Fig. A.

• Unpack the welder system.

•

Check that the welding apparatus is in good condition, other-

wise immediately inform the retailer or distributor.

•

Check that all ventilation grilles are open and that no objects

obstruct the free passage of air.

•

Lastly mount the handle, pivot and eyebolts following the de-

scription given in Fig. A.

How to lift up the system

Before lifting the unit, open the bag containing the eyebolts (at-

tached to machine), remove the two eyebolts complete with fi-

bre washers and mount them on the upper part of the cover.

IMPORTANT: Only lift the unit using the two eyebolts.

The wire-feeder has a handle and a hook so that it can be

hung up.

NOTE: The lifting and transporting devices conform with Eu-

ropean regulations. Do not use other equipment to lift or trans-

port the feeder.

Table 1

Model MAXI 405 MAXI 505

Three-phase power supply 50/60 Hz V 230/400

Mains supply: Z

max

Ω (*)

Power input @ I

2

Max kVA 19,0 24,2

Delayed fuse (I

2

@ 60%) A 35/20 40/25

Power factor / cosφ 0,96 0,97

Maximum efficiency degree η 0,75 0,71

Open circuit voltage V 20 ÷ 44 19 ÷ 51

№ of adjustments 20 30

Current range A 60 ÷ 400 60 ÷ 500

Duty cycle @ 100% (40°C) A 230 300

Duty cycle @ 60% (40°C) A 300 370

Duty cycle @ 35% (40°C) A 400 500

Wire diameter mm 0,6 ÷ 1,6 0,8 ÷ 2,0

Standards

IEC 60974-1

IEC 60974-10

Insulation class IP 23 S

Protection class H

Dimensions

mm 1060 - 780 - 600

Weight kg 99 113

(*) IMPORTANT:

•

This plant meets the requirements laid down in the EN/IEC 61000-

3-12 standard on harmonic currents.

•

This system, tested according to EN/IEC 61000-3-3, meets the re-

quirements of EN/IEC 61000-3-11.

FIG. A

2000H928

Loading...

Loading...