Pag.26

6.8 REDUCER

1. Disassemble the prop hub like chapter 6.6

2. Disassemble the reducer from the engine and

remove the 4 fixing cap screw

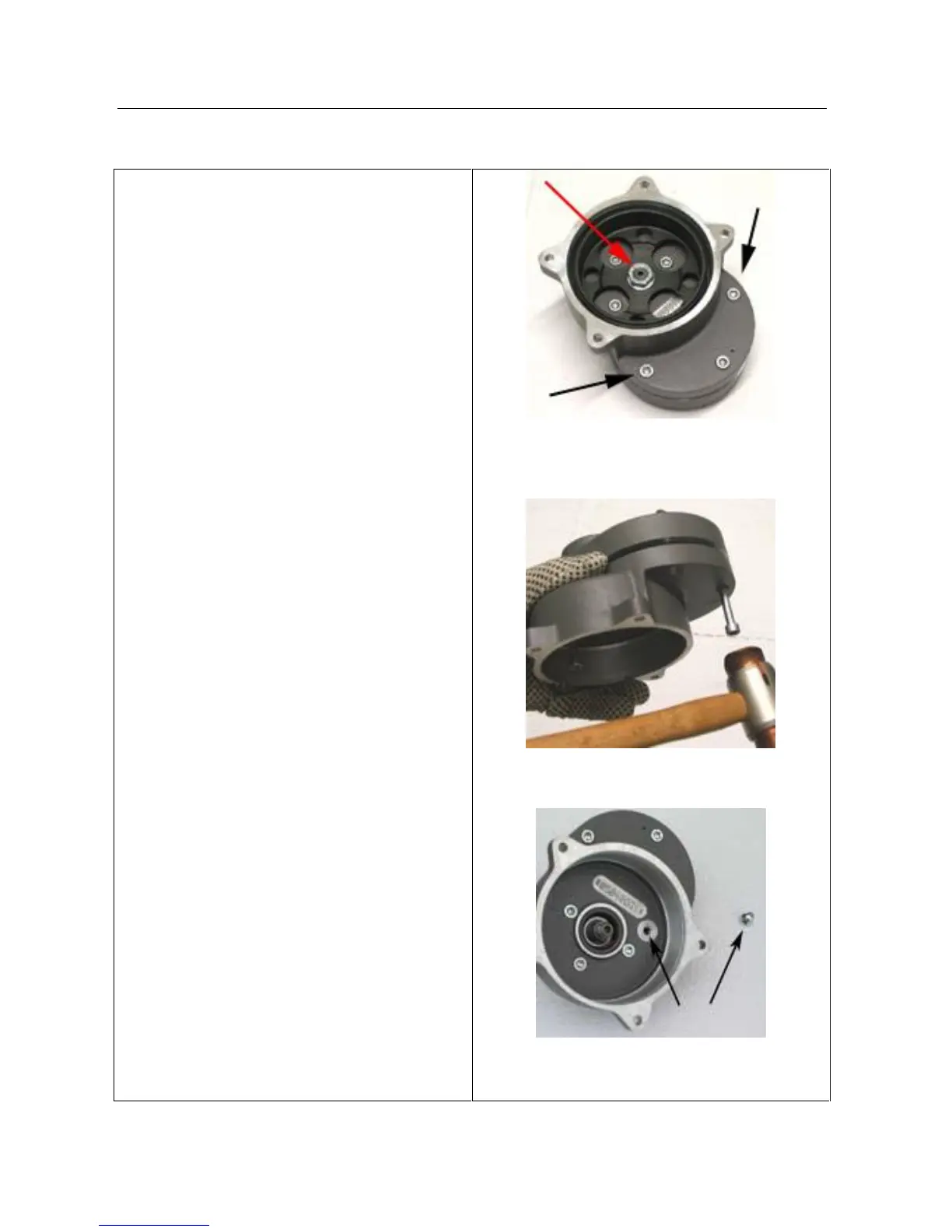

3. Remove the bolt from clutch bell (Fig.32)

with impact tool.

4. Take off the clutch bell with the exstactor

indicated (art. 100.201 Two-Jaws pullers)

5. Tighten the 2 cap screw in the position into

(Fig.33) and tap gently

6. For disassembling the bearing utilize a air

heater of 150° (hair-dryer)

7. Clean all and utilize a silicone gasket at thin

thickness.

8. Assembly the 2 carter in the right position

with gear and pin

CAUTION: Utilize manual press to get together

the crankcase

9. Tighten the screw at the specified torque

• TORQUE: 12Nm( 1,2 kgf/m

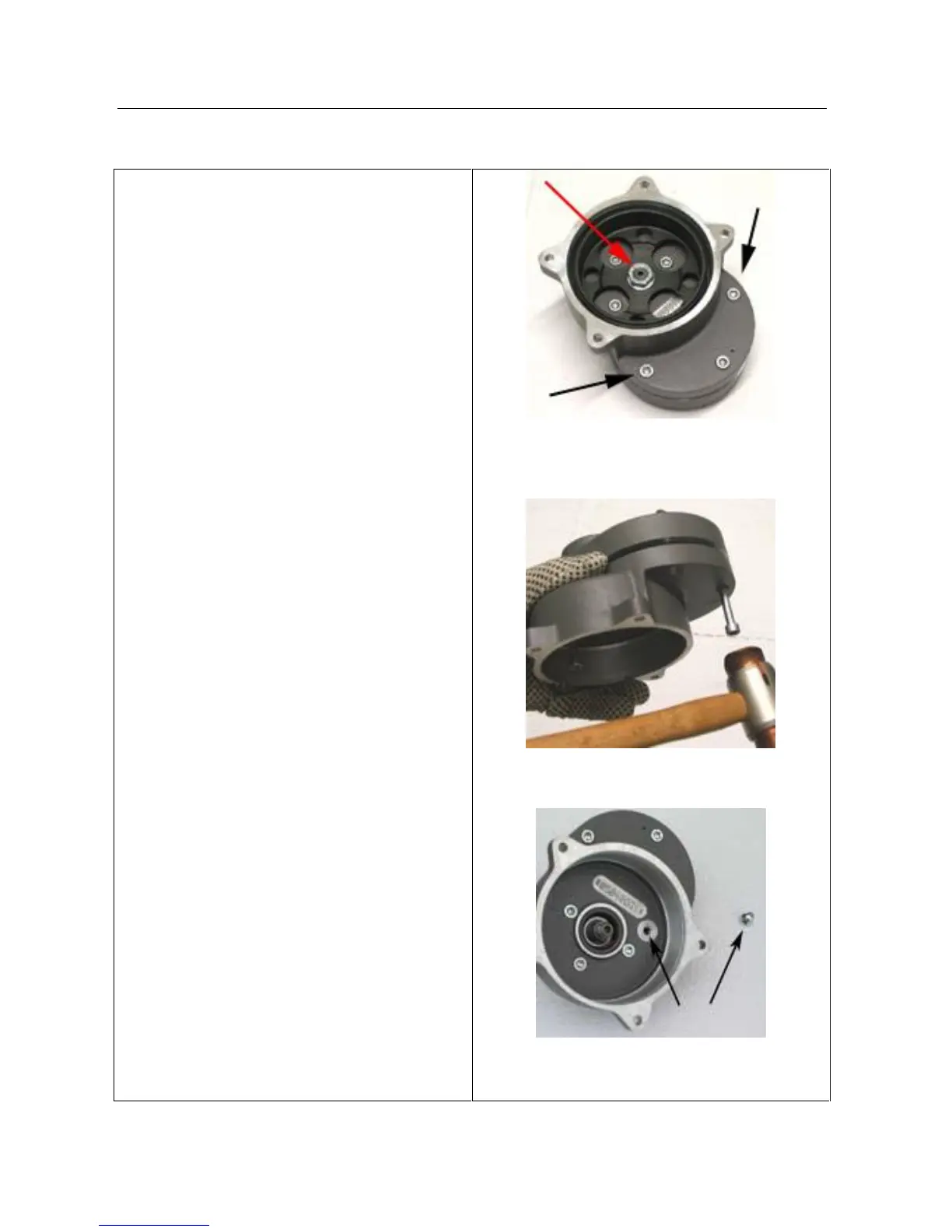

10. Insert into the hole indicated (Fig.34) with

lever operated grease pumps, 15 ml. of fat* .

Utilize a balance to verify if you insert the

correct quantity of fat Approximately 20 Gr.

11. Tighten the cup at the specified torque

• TORQUE: 12Nm ( 1.2 kgf/m)

12. Assemble the clutch bell into the clutch

tightening the bolt with locking agent at the

specified torque

• TORQUE: 300Nm ( 30 kgf/m)

*Grease type:

SINTOFLON GS2211NLGI classe00

BECHEM Berulub FG 8 EP NLGI classe00

Fig.32

Fig. 33

Fig. 34

Loading...

Loading...