Pag. 9

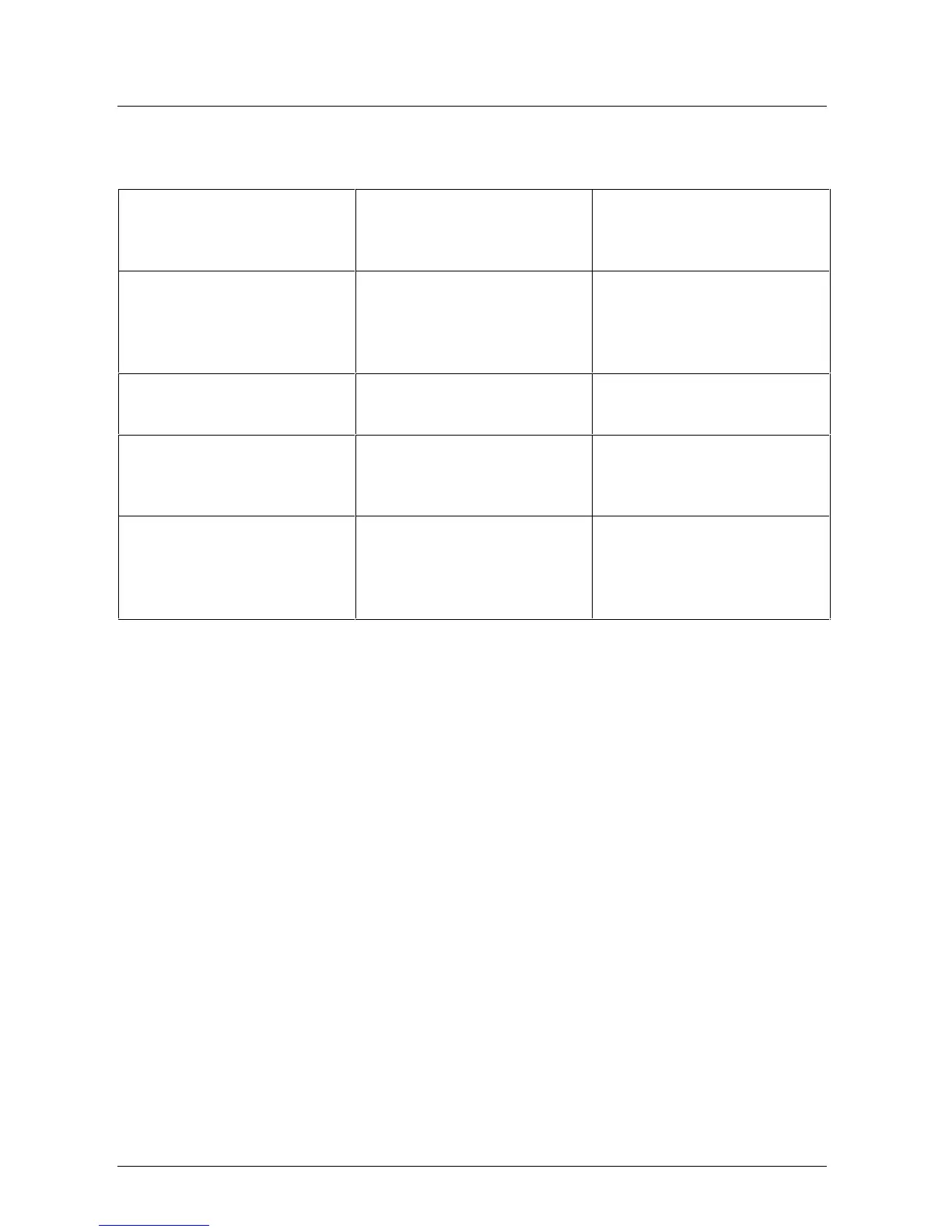

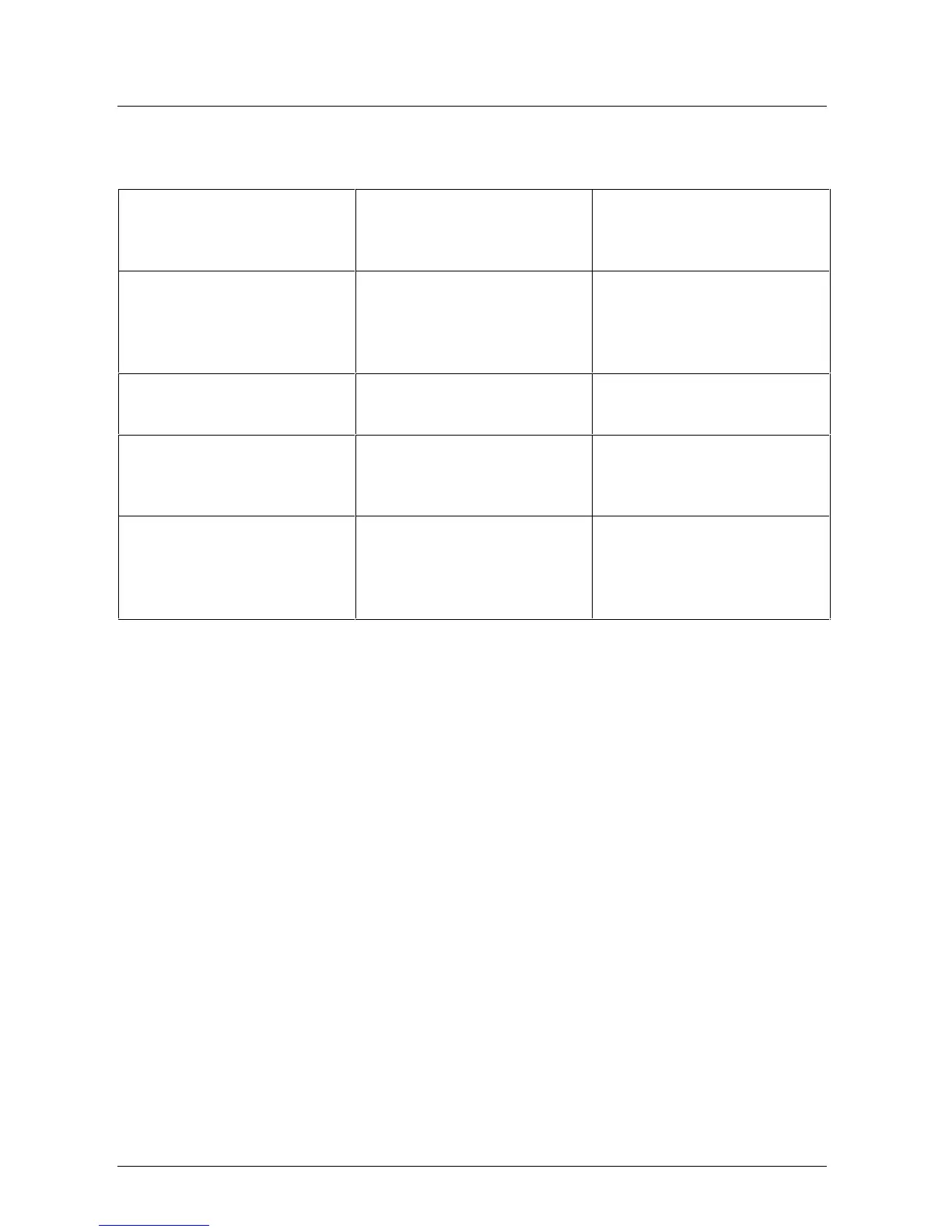

3.3 MAINTENANCE SCHEDULE

FREQUENCY INSPECT REPLACE

Before and after each use All screw nuts, bolts correctly

tigthen, silent-block in, and

check carburation.

Every 100 hours Cylinder head decarbonizing

and cleaning sponge filter

Complete piston

Reducer’s lubricant

Every 200 hours Diameter clutch, usury of the

bell clutch, and glass wool of

the silencer

Crankshaft bearing ,bearing

reducer, oil reducer, crankshaft

seals, thermical group,

connecting rod.

Each year All rubber and plastic

components.

Fuel diphragms of carburettor ,

spark plug.

Loading...

Loading...