3-5. Disassembly, Reassembly and Lubrication

3-39 CLP-621 & CLP-631

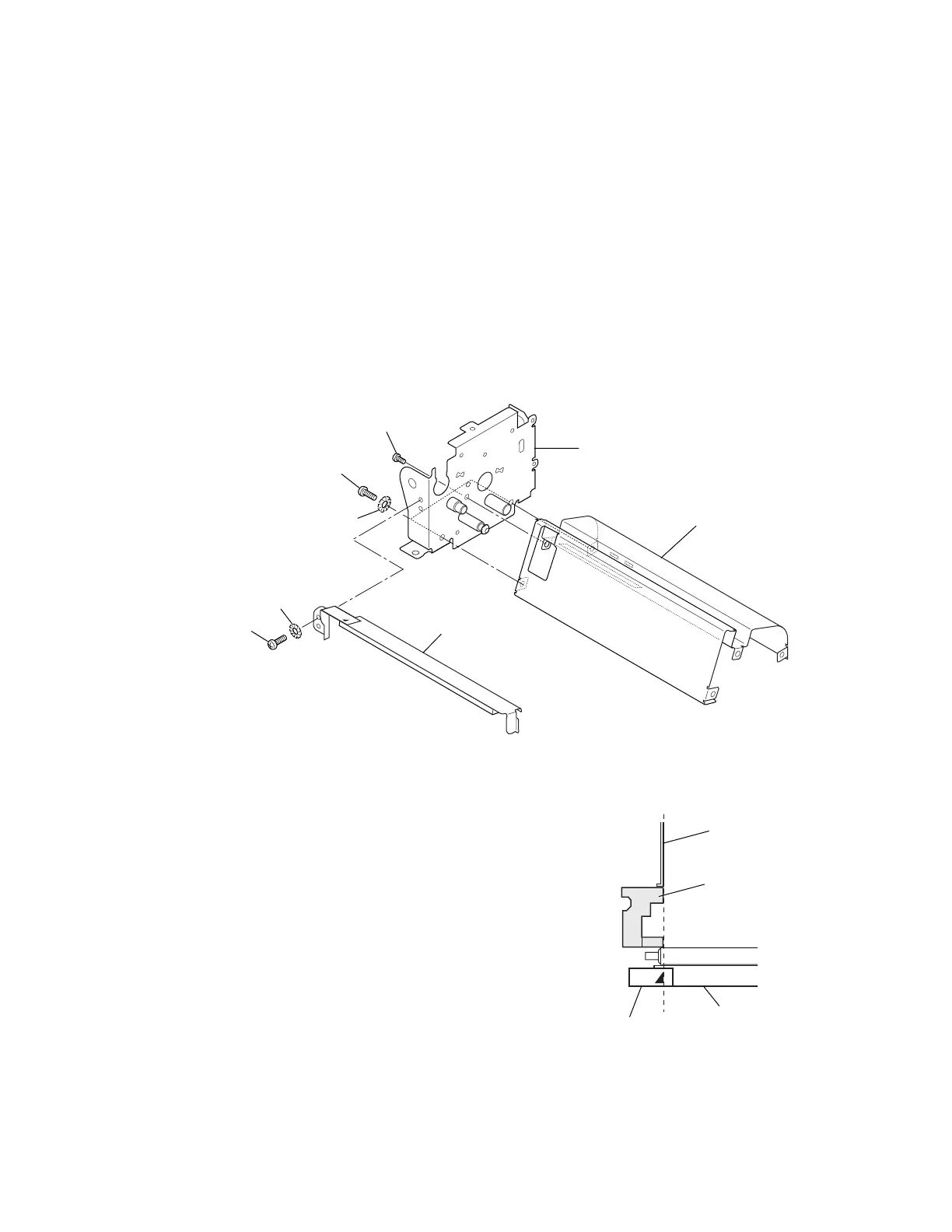

3-5-24. Main Frame, Main Plate L SA and Plate Peeler SA

1. Remove the Mechanism Unit. Refer to 3-5-13 “Mechanism Unit and Case L”.

2. Remove the PF Unit. Refer to 3-5-17 “Head Block and PF Unit”.

3. Remove the Motor SA. Refer to 3-5-20 “Motor SA”.

4. Remove the Sensor Guide Shaft (with the Sensor Holder L SA and the Paper Set Guide).

Refer to steps 1 to 4 in 3-5-21 “Reflective Sensor PCB SA”.

5. Remove 3 gears. Refer to 3-5-22 “Gears”.

6. Remove the Main Plate R Unit. Refer to steps 1 and 2 in 3-5-23 “Head Lock Lever and Main

Plate R SA”.

7. Remove 2 screws (BH (N), M3x6), 2 washers (EXT. T, 3 (NI)) and 1 screw (NO.0, PH (#1),

M2.6x6), and detach the Main Frame.

8. Remove 1 screw (BH (N), M3x6) and 1 washer (EXT. T, 3 (NI)) and detach the Plate Peeler SA

from the Main Plate L SA.

Frame, Main

SA, Main Plate L

BH (N), M3x6

NO.0, PH (#1), M2.6x6

SA, Plate Peeler

EXT. T, 3 (NI)

BH (N), M3x6

EXT. T, 3 (NI)

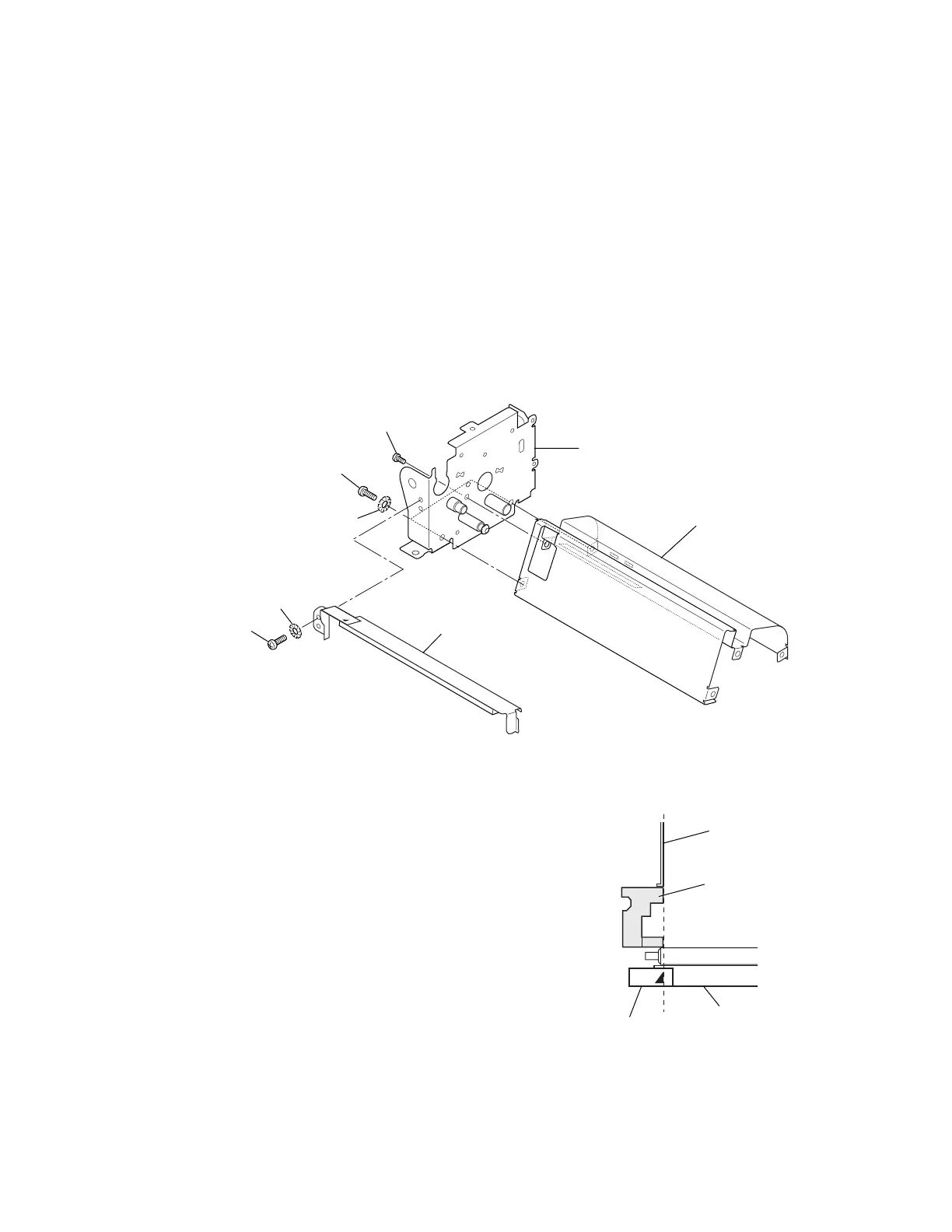

Note on reassembling:

• Media-path left-edge alignment when assembling the Plate

Peeler SA:

When assembling the Plate Peeler SA, align the arrow mark

on the Plate Peeler SA with the media contacting surface of

the Head Wire Cover as shown.

Also, when you stick a new Mark Label, align its arrow mark

with the media contacting surface of the Head Wire Cover.

(When assembling the Mechanism Unit, the media guide end

of the Head Wire Cover should be aligned with the chassis

plate of the Main PCB Block (as explained in 3-5-13

“Mechanism Unit”). Then, the media-path left-edges are

aligned on the basis of the Mark Label.

Cover, Head Wire

(Media Guide End)

Mark Label

Main PCB Block

(Media Guide End)

SA, Plate Peeler

Align.

Loading...

Loading...